Imagine your locomotive as a well-oiled machine, seamlessly gliding along the tracks with precision and efficiency. The key to achieving this level of performance lies in the optimal choices you make when selecting locomotive contactors.

These crucial components play a significant role in enhancing your locomotive’s capabilities and ensuring smooth operations. By understanding the impact of high-quality contactors on your electrical systems, you can unlock a world of possibilities for maximizing performance and reliability. Curious to explore how the right contactors can transform your locomotive’s operation?

Key Takeaways

- Upgrading to high-quality contactors enhances locomotive performance and efficiency.

- Efficient contactors optimize power distribution for reliability and safety.

- Regular maintenance practices ensure optimal contactor functionality and longevity.

- Battery integration and advanced generators contribute to sustainable and efficient locomotive operations.

Locomotive Electrical Systems

When exploring the points related to locomotive electrical systems, you should focus on an essential components overview, system maintenance practices, and efficiency improvement strategies. Understanding the key components and how they interact within the system is crucial for maintaining optimal performance. By implementing effective maintenance practices and efficiency improvement strategies, you can enhance the reliability and functionality of locomotive electrical systems.

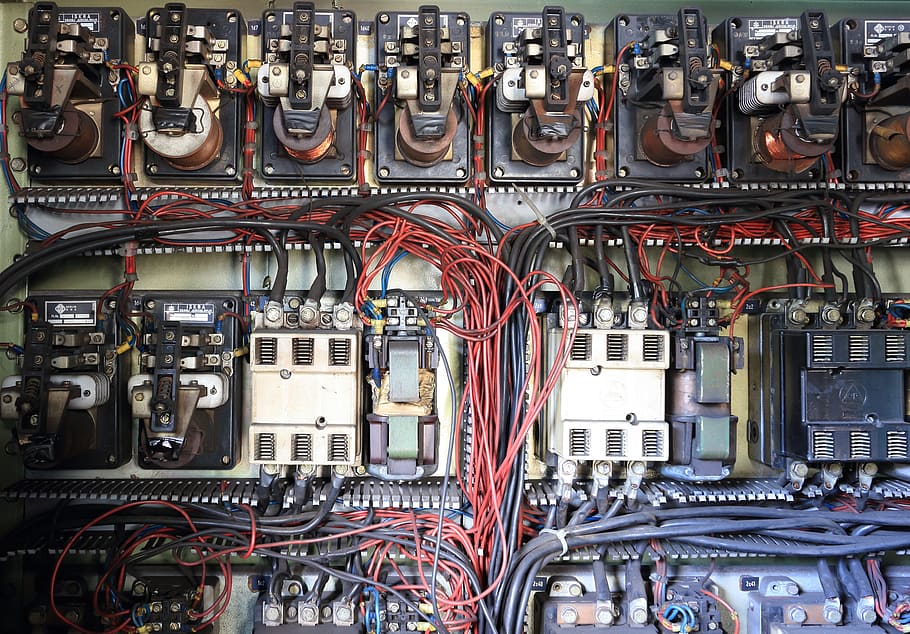

Essential Components Overview

To understand the intricate workings of locomotive electrical systems, you must grasp the pivotal role that locomotive contactors play in regulating power distribution and ensuring safe and efficient operation. Locomotive contactors are critical electrical components that control the flow of power to various systems on the locomotive, helping manage the electrical current to motors, lights, heaters, and other essential functions. These components are designed to handle high currents and voltages, making them essential for reliable performance. Contactors play a key role in power regulation, optimizing performance, and current management. Understanding the function and importance of contactors is crucial for maintaining optimal locomotive electrical systems, contributing to the overall safety and efficiency of rail transportation.

System Maintenance Practices

Regularly inspecting, cleaning, and testing components such as contactors, relays, wiring, and connectors is essential for maintaining the optimal performance and reliability of locomotive electrical systems. To ensure effective system maintenance, adhere to the following practices:

- Inspection Techniques: Use thorough examination methods to identify potential issues early.

- Safety Protocols: Follow strict safety guidelines to protect personnel and equipment during maintenance.

- Component Reliability: Assess the durability and performance of contactors, relays, and wiring regularly.

- Preventive Measures: Implement proactive maintenance schedules to prevent unexpected failures and extend component lifespan.

Proper maintenance training is crucial for personnel to understand inspection techniques, safety protocols, and preventive measures for maintaining locomotive electrical systems efficiently.

Efficiency Improvement Strategies

How can implementing advanced contactors enhance the efficiency of locomotive electrical systems? Upgrading to high-quality contactors can lead to significant improvements in energy savings, performance optimization, reliability enhancement, overheating prevention, and maintenance cost reduction. By selecting the best contactors for locomotives, operators can ensure efficient power distribution, minimize energy losses, and optimize electrical performance. Utilizing efficient contactors plays a crucial role in regulating electrical currents, reducing maintenance costs, and preventing overheating and electrical failures. This proactive approach not only enhances the overall efficiency of locomotives but also contributes to energy savings, increased reliability, and improved performance on the railway.

| Efficiency Improvement Strategies | Benefits |

|---|---|

| Energy savings | Reduced operational costs |

| Performance optimization | Enhanced system efficiency |

| Reliability enhancement | Improved system reliability |

Battery Power in Locomotives

Integrating battery power into locomotives revolutionizes energy storage and delivery for enhanced electrical component performance. This advancement brings about a significant shift in how locomotives operate, providing a range of benefits that optimize overall efficiency and sustainability. Here are some key points to consider:

- Battery Technology: Incorporating advanced battery technology, such as Nickel Cadmium and Lithium-ion batteries, ensures reliable power sources for locomotives, enhancing their performance capabilities.

- Energy Storage: Battery-powered locomotives excel in efficiently storing and delivering energy to various electrical components, enabling smooth operations and reducing downtime.

- Environmental Impact: By reducing emissions and promoting sustainability, battery-powered locomotives contribute to a cleaner and greener transportation system, aligning with eco-friendly initiatives.

- Operational Flexibility: The use of batteries in locomotives offers operational flexibility, particularly in areas without overhead power lines, allowing for increased versatility in rail transportation.

Generator Functionality

When considering generator functionality in locomotives, focus on optimizing efficiency enhancements, regulating power output, and implementing maintenance best practices. Understanding how generators convert mechanical energy into electrical power for various systems is crucial for maximizing locomotive performance. Proper monitoring and care for generators ensure continuous power supply and reliable locomotive operation.

Generator Efficiency Enhancements

Enhancing locomotive generator efficiency involves optimizing the conversion of mechanical energy into electrical energy for improved performance and reduced environmental impact. To achieve this goal effectively, consider the following:

- Implement energy optimization techniques to maximize the efficiency of the generator.

- Enhance performance through the integration of advanced generator advancements.

- Upgrade generator components and systems to boost efficiency levels.

- Improve electrical efficiency by employing cutting-edge control systems.

Power Output Regulation

To optimize locomotive performance, ensuring precise regulation of power output from generators is essential in maintaining operational efficiency and controlling speed effectively. Power output optimization is crucial for the overall functionality of the locomotive. Voltage regulation techniques help in stabilizing the electrical supply to different components, while current control mechanisms ensure that the right amount of power is distributed. Speed management strategies rely on the accurate control of power output to adjust locomotive speeds as needed. Efficiency enhancement methods are implemented through the proper regulation of power output, contributing to the safe and reliable operation of the locomotive. The table below summarizes the key elements related to power output regulation in locomotives:

| Power Output Optimization | Voltage Regulation Techniques | Current Control Mechanisms |

|---|---|---|

| Ensure efficiency | Stabilize electrical supply | Control power distribution |

| Regulate speed effectively | Maintain consistent voltage | Monitor power flow |

| Enhance operational efficiency | Prevent voltage fluctuations | Adjust current levels |

| Optimize locomotive performance | Control electrical output | Regulate power supply |

| Ensure safe and reliable operation | Ensure stable voltage | Manage power distribution |

Maintenance Best Practices

Inspecting locomotive generator contactors regularly is a critical maintenance practice to prevent malfunctions and ensure optimal functionality. To maintain peak performance of the generator, follow these best practices:

- Contactor cleaning: Regularly clean contactor components to remove dirt and debris that can affect their operation.

- Lubrication techniques: Apply recommended lubricants to contactor parts to reduce friction and wear, extending their lifespan.

- Voltage testing: Conduct regular voltage tests to ensure that the contactors are receiving and transmitting the correct voltage levels.

- Current flow analysis: Monitor the current flow through the contactors to detect any irregularities that may indicate potential issues.

Motor Mechanisms

Selecting the appropriate motor contactors for locomotives is essential for optimizing the efficiency and reliability of their electrical systems. Motor contactors in locomotives play a vital role in controlling the electrical current flow to the motors, enabling their operation. These components help manage the start, stop, and direction of locomotive motors efficiently, contributing to overall performance optimization. Contactors are crucial for ensuring the smooth and safe functioning of locomotive motors, protecting them from electrical overload by opening or closing the circuit as needed.

To enhance motor operation, it is important to focus on current regulation through the proper selection and maintenance of contactors. By adhering to maintenance tips and guidelines, operators can ensure that the contactors function effectively, promoting electrical safety and preventing potential issues that could lead to downtime. Regular inspection and testing of contactors are essential for identifying any issues early on and addressing them promptly to maintain optimal performance. By prioritizing the selection of high-quality contactors and implementing proactive maintenance practices, operators can maximize the longevity and efficiency of locomotive motor mechanisms.

Traction Control Insights

Enhancing the efficiency and reliability of locomotive electrical systems requires a keen focus on traction control insights, crucial for optimizing power delivery to traction motors and ensuring operational safety and effectiveness. When delving into traction control technology, several key aspects need consideration:

- Motor Performance: Traction control systems are pivotal in managing and enhancing the performance of traction motors, ensuring optimal power delivery and efficiency.

- Contactors Reliability: The reliability of contactors is paramount in traction control systems, as they are responsible for switching high current circuits to regulate motor operations effectively.

- Wheel Slip Prevention: Traction control technology aids in managing wheel slip, ensuring maximum adhesion between the wheels and the track for safe and efficient locomotive operation.

- Speed Regulation Strategies: Effective speed control strategies are implemented through traction control systems to maintain operational safety and efficiency, allowing for precise regulation of locomotive speeds.

Electrical Circuitry Benefits

Controlling the flow of electricity within locomotive systems, locomotive contactors play a vital role in optimizing power distribution and enhancing overall performance. Voltage regulation is a key benefit provided by these contactors, ensuring that the electrical systems receive the appropriate voltage levels for efficient operation. Moreover, current management is crucial in maintaining the balance of electrical currents flowing through different components, preventing overloads and potential damage.

Efficient power distribution is another advantage offered by locomotive contactors. By directing electricity to the necessary parts of the locomotive system, these components enable smooth operation and effective utilization of power. This optimized distribution contributes to energy efficiency, reducing wastage and promoting a more sustainable operation.

In addition to managing voltage and current, contactors play a significant role in performance optimization. Their ability to enable quick and reliable switching of electrical currents enhances the overall functionality of locomotive systems. By ensuring that the right amount of power is delivered to each component at the right time, contactors help maximize performance and minimize disruptions during operation.

Diagnostic System Advantages

Utilizing diagnostic systems in locomotive contactors provides real-time monitoring capabilities for assessing performance metrics. These systems offer a range of advantages that significantly contribute to the efficiency and reliability of locomotive operations:

- Performance Monitoring: Diagnostic systems continuously track key performance indicators, allowing operators to gauge the effectiveness of the contactors in real-time.

- Early Detection: By detecting issues at their onset, these systems enable early intervention, preventing potential malfunctions and minimizing downtime.

- Preventive Maintenance: The ability to identify and address issues proactively through diagnostic systems facilitates scheduled maintenance, reducing the likelihood of unexpected breakdowns.

- Reliability Enhancement: Through detailed monitoring and analysis, these systems enhance the overall reliability of locomotive contactors, ensuring consistent performance and operational safety.

Frequently Asked Questions

How Do Locomotive Contactors Differ From Regular Electrical Contactors?

When comparing locomotive contactors to regular electrical contactors, you’ll notice significant differences. Locomotive contactors are built to withstand the demanding conditions of rail operations, with enhanced electrical and mechanical features. They use robust contact materials and are designed to handle higher operating voltages and current capacities. These specialized contactors ensure reliable performance and safety in locomotive electrical systems, catering specifically to the unique requirements of rail transportation.

What Are the Key Factors to Consider When Selecting Contactors for Battery-Powered Locomotives?

When selecting contactors for battery-powered locomotives, key factors include contactors selection, maintenance, performance optimization, efficiency enhancement, and traction control advancements. The right contactors are crucial for regulating electricity flow, controlling speed, and maintaining overall performance. By choosing high-quality contactors tailored to locomotive requirements, operators can ensure smooth operations and reduce downtime, ultimately contributing to safe and efficient rail transportation.

How Do Contactors Contribute to the Overall Efficiency of Generator Functionality in Locomotives?

When it comes to the efficiency of generator functionality in locomotives, contactors are key players. They optimize efficiency, enhance performance, and contribute to traction control. By comparing different contactor options, you can determine the best fit for your locomotive’s needs. The right contactors regulate electricity flow, ensure smooth operations, and maintain overall performance, crucial for safe and efficient rail transportation. Choose wisely for optimal generator functionality in your locomotives.

Can Contactors Impact the Performance and Lifespan of Locomotive Motors?

When it comes to the impact on performance and lifespan of locomotive motors, contactors play a crucial role. Optimal contactor selection directly influences the efficiency of electrical systems in battery-powered locomotives. By regulating electricity flow and ensuring proper traction control, high-quality contactors contribute to extended motor lifespan and enhanced overall performance. Advancements in technology further improve efficiency and reliability, making contactor choice essential for safe and efficient rail transportation.

Are There Specific Technologies or Features in Contactors That Improve Traction Control in Locomotives?

When it comes to traction control in locomotives, specific technologies and features in contactors can significantly improve performance. Advanced contactors with enhanced traction control capabilities can optimize efficiency, regulate electricity flow, and maintain speed control. These features not only contribute to better traction control but also impact the overall performance and lifespan of locomotive motors. Selecting contactors designed for traction control can ensure safe and efficient rail transportation.

Conclusion

By carefully selecting high-quality contactors for your locomotive, you can significantly enhance its performance and ensure smooth operations. Optimal choices in contactors play a crucial role in managing electricity flow, regulating speed, and optimizing overall locomotive functionality. With the right contactors in place, you can maximize efficiency, reduce disruptions, and achieve your operational goals with ease. Make informed decisions when it comes to choosing contactors for your locomotive to elevate its capabilities and enhance its reliability.

If you want to read further in detail on this topic, check out: Maintenance of Electromagnetic Contactor On Electric Locomotive.