Welcome to our comprehensive guide on the WABCO locomotive air brake system. This document provides a detailed overview of the system, its components, and their functions. The 26L air brake system is critical for ensuring the safe and efficient operation of locomotives. We will delve into the intricacies of the WABCO brake valve, offering free information and practical insights. Our aim is to provide a clear understanding of this essential technology, enabling you to maintain and troubleshoot your locomotive’s brake system effectively.

Understanding the WABCO Locomotive Air Brake System

Introduction to Locomotive Air Brake Technology

Locomotive air brake technology is a vital safety component in railway operations. The air brake system allows the operator to control the speed and stopping ability of the train. Central to this system is the WABCO valve, which regulates the air pressure and distributes it to the brake cylinders on each car of the train. The WABCO system is designed for reliable and consistent braking performance, enhancing safety and efficiency on the railways. Understanding the principles of air brake technology is essential for anyone involved in locomotive maintenance and operation.

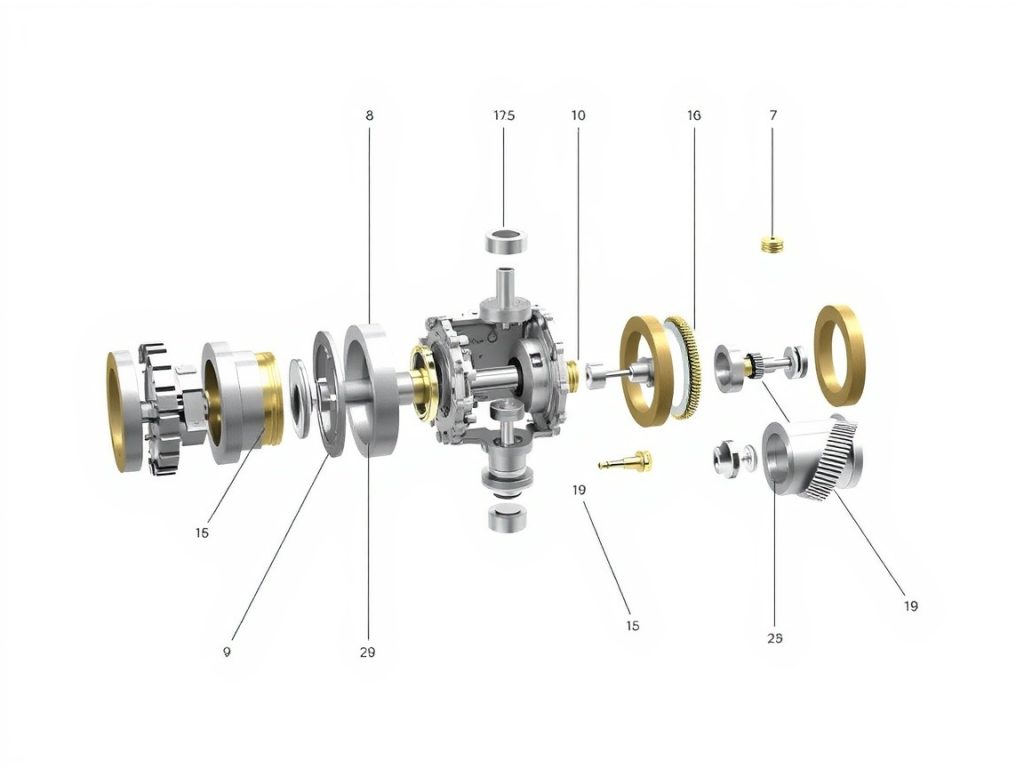

Components of the WABCO Brake Valve

The WABCO brake valve consists of several key components working in harmony. These include the service valve, the emergency valve, and various control chambers that regulate air flow. Each component plays a specific role in the operation of the air brake system. The complex interplay of these components enables the WABCO valve to provide precise control over the braking force applied to the train. Understanding these components is essential for troubleshooting and maintenance. Mikura International provides high-quality replacement parts for all WABCO valve components.

Functions of the Air Brake Valve

The primary function of the WABCO air brake valve is to control the application and release of air pressure to the brake cylinders. This control allows the engineer to initiate service braking for controlled stops, emergency braking for immediate halts, and to maintain a constant brake pressure while descending grades. The WABCO system ensures the brake system responds accurately to the engineer’s commands, providing the safety and reliability required for modern rail operations. The valve’s ability to modulate air pressure ensures smooth and safe braking, preventing wheel lockup and ensuring optimal stopping distances.

Technical Specifications of WABCO Locomotive Brake Valves

Key Technical Features

The 26L air brake system, featuring the WABCO valve, is characterized by several key technical features. These include its robust design, precise control mechanisms, and reliable performance under various operating conditions. The valve is engineered to maintain consistent air brake pressure, ensuring optimal braking force. With the use of high-quality materials, the WABCO system offers longevity and minimal maintenance. The 26L system‘s modular design allows for ease of maintenance and replacement of individual components, enhancing overall efficiency. The specifications are available as free information.

Performance Metrics and Standards

The performance of the WABCO 26L air brake system is measured against stringent industry standards, ensuring reliable and safe operation. Key performance metrics include brake response time, pressure regulation accuracy, and overall braking efficiency. The system must meet or exceed these standards to guarantee consistent performance in all operating conditions. Regular testing and maintenance are crucial to upholding these performance standards. Mikura International ensures that all replacement parts meet these rigorous requirements. You can freely download as a PDF file to check performance standards

Compatibility with Locomotive Systems

The WABCO 26L air brake system is designed for broad compatibility with various locomotive models and configurations. The valve is engineered to integrate seamlessly with existing locomotive control systems, ensuring reliable performance without extensive modifications. Its adaptability makes it a versatile choice for diverse railway operations. Understanding the compatibility requirements is crucial for proper installation and maintenance. Mikura International can provide support in determining WABCO part compatibility. Feel free to ask us for more information regarding this topic.

Common Issues and Troubleshooting Tips

Identifying Common Locomotive Brake Valve Problems

Several common issues can affect the performance of the WABCO locomotive brake valve, including air leaks, sticking valve components, and pressure irregularities. Identifying these problems early is crucial for preventing more significant issues. Regular inspection of the 26L system can help detect these issues. Recognizing the symptoms of these problems allows for prompt troubleshooting and maintenance. The WABCO system, if regularly checked, can provide a safe and efficient use. Free your mind by troubleshooting these issues.

Practical Troubleshooting Steps

When troubleshooting the WABCO air brake system, start by checking for air leaks and inspecting the condition of valve components. Use a pressure gauge to verify correct pressure levels within the 26L system. Clean and lubricate any sticking components to ensure smooth operation. Refer to the manufacturer’s manual for detailed troubleshooting procedures. Mikura International provides free resources and support to assist with these steps. You can freely download as a PDF file and check troubleshooting steps.

When to Seek Expert Assistance

For complex issues such as internal valve damage or persistent system failures, it’s best to consult with a qualified technician. Attempting to repair these issues without proper training can lead to further damage or safety risks. Contact Mikura International for access to qualified service providers and expert guidance on maintaining your 26L brake system. With the right approach, the WABCO valve is a safe system to use. We are here to help you and give you free information.

Maintenance Best Practices for WABCO Locomotive Air Brake Valves

Routine Maintenance Checklist

Regular routine maintenance is essential for ensuring the reliable operation of the WABCO air brake system. A comprehensive checklist should include several key inspections:

| Component | Action |

|---|---|

| Valve components | Inspect for wear or damage. |

| Air brake system | Check for leaks and verify proper pressure levels. |

Lubricate moving parts to prevent sticking and ensure smooth operation. Inspect the condition of hoses and fittings, replacing any that show signs of deterioration. Follow this checklist consistently to maintain the integrity of your 26L brake system.

Expert Insights on Long-term Care

For long-term care of your WABCO air brake system, consider the following:

| Area | Recommendation |

|---|---|

| Parts | Use high-quality replacement parts from Mikura International. |

| Maintenance | Implement a proactive maintenance schedule. |

| Personnel | Regularly train maintenance personnel. |

By following these insights, you can extend the lifespan of your WABCO valve and minimize downtime. We are here to help you and give you free information.

Benefits of Regular Maintenance

Regular maintenance ensures optimal performance, extends system lifespan, minimizes costly repairs, maintains operational efficiency, and reduces downtime. The benefits of regular maintenance on your WABCO 26L air brake system are numerous. Regular maintenance ensures optimal performance of the WABCO valve, enhancing safety and reducing the risk of accidents. Regular maintenance also extends the lifespan of the system, minimizing costly repairs and replacements. This proactive approach helps maintain operational efficiency and minimizes downtime. In the long run, regular maintenance saves time and money, making it a worthwhile investment for any locomotive operator.

Conclusion and Actionable Advice

Summary of Key Takeaways

The WABCO locomotive air brake system is critical for safe and efficient railway operations, and regular maintenance is essential. Understanding the system’s components, functions, and technical specifications is essential for effective maintenance and troubleshooting. Regular maintenance, including inspections, lubrication, and timely repairs, ensures optimal performance and longevity of the WABCO valve. By following expert insights and addressing common issues promptly, you can minimize downtime and maximize the reliability of your 26L brake system. Mikura International provides free information regarding the system. You can also freely download as a PDF file.

Next Steps for Implementation

Implement best practices by regularly reviewing your maintenance plan to maintain the integrity of the WABCO air brake system. To support this, consider the following key areas:

| Area | Action |

|---|---|

| Maintenance Schedule | Create a detailed schedule tailored to your specific locomotive and operating conditions. |

| Personnel Training | Train your maintenance personnel on the proper inspection and troubleshooting procedures. |

Source high-quality replacement parts from Mikura International to ensure compatibility and reliability. Regularly review and update your maintenance plan to reflect changes in operating conditions or new technological advancements.

Contacting Mikura International for Sales and Support

Contact Mikura International for high-quality replacement parts, expert technical support, and customized maintenance solutions. For all your WABCO locomotive air brake system needs, contact Mikura International. We offer a wide range of high-quality replacement parts, expert technical support, and customized maintenance solutions. Our experienced team can assist you with troubleshooting, maintenance planning, and product selection. Contact us today to learn more about how Mikura International can help you optimize the performance and reliability of your 26L brake system. We are here to provide you with free information.

Q: What is the WABCO Locomotive Air Brake Valve system?

A: The WABCO Locomotive Air Brake Valve system is a critical component in locomotive braking systems, designed to control air flow and pressure for efficient braking performance, ensuring safety and reliability during operations.

Q: How does the WABCO air brake valve work?

A: The WABCO air brake valve operates by regulating air pressure in the braking system. It receives signals from the engineer or the train control system, which activates the valve to either apply or release the brakes based on real-time requirements.

Q: What are the main features of the WABCO Locomotive Air Brake Valve?

A: Key features of the WABCO Locomotive Air Brake Valve include automatic application and release of brakes, pressure regulation, and enhanced reliability under various operating conditions, making it suitable for modern locomotives.

Q: What maintenance is required for the WABCO air brake valve?

A: Regular maintenance for the WABCO air brake valve includes inspecting for leaks, checking air pressure settings, and ensuring that the valve operates smoothly without any obstructions or wear that could affect performance.

Q: What troubleshooting steps can be taken if the WABCO air brake valve is not functioning properly?

A: If the WABCO air brake valve is not functioning, troubleshooting steps include checking for air leaks, verifying the electrical connections, inspecting for mechanical obstructions, and ensuring proper air pressure levels in the system.

Q: Are there specific training requirements for technicians working on WABCO air brake valves?

A: Yes, technicians working on WABCO air brake valves typically need specialized training on the system, including understanding its operation, maintenance procedures, and safety protocols to ensure effective handling and repair.

Q: How can I obtain replacement parts for WABCO Locomotive Air Brake Valves?

A: Replacement parts for WABCO Locomotive Air Brake Valves can be obtained through authorized WABCO distributors or service centers, where you can also find guidance on the ordering process and available parts.

Q: What are the safety features of the WABCO Locomotive Air Brake Valve?

A: The WABCO Locomotive Air Brake Valve includes safety features such as automatic fail-safe mechanisms that prevent unintended brake applications, pressure monitoring systems, and robust construction to withstand harsh operating conditions.