When a locomotive shuts down after a hard pull, the turbocharger is still extremely hot-but the oil flow that was keeping it cool stops almost instantly.

That’s when oil starts to overheat, oxidize, and coke on hot bearing and seal surfaces. Over time, this silent damage shortens turbo life, drives unplanned outages, and inflates overhaul costs.

Key pain points Turbo Soak Back Pump 40182032 is designed to address in locomotive turbochargers:

- Oil coking in the turbo center housing during hot soak after shutdown

- Varnish and hard carbon deposits on bearings and seal rings

- Sticking or dragging bearings leading to slow spool-up and power loss

- Increased turbo failures between scheduled overhauls

- Higher lube oil contamination and filter loading from coke debris

- Extended locomotive downtime due to turbo change-outs and inspections

- Unpredictable performance on hot days or after heavy load cycles

- Difficulty meeting OEM-recommended turbocharger life targets

- Rising lifecycle cost per turbocharger over the locomotive’s service life

How Pump 40182032 Helps You Overcome These Issues

| Problem / Symptom | Root Cause During Hot Soak | What Pump 40182032 Does | Operational Benefit for the Locomotive |

|---|---|---|---|

| Bearing oil coking after shutdown | Stagnant oil exposed to residual turbo heat | Maintains controlled oil circulation post-shutdown | Prevents coke formation on bearing surfaces |

| Varnish and deposits in turbo core | Localized overheating of trapped oil | Keeps oil moving to remove heat from core | Cleaner internals and smoother bearing operation |

| Frequent turbo overhauls or replacements | Progressive deposit buildup and bearing distress | Reduces thermal stress on oil and components | Longer intervals between turbo overhauls |

| Slow turbo response, reduced power | Deposits increasing friction and drag | Protects bearing clearances and surface finish | Faster spool-up, more consistent horsepower |

| Oil filter plugging, dirty crankcase oil | Coke particles flushed into engine lube system | Minimizes coke generation at the turbo source | Lower contamination load on engine oil system |

Like a slow bake in a hot engine compartment, a locomotive turbo’s hot soak after shutdown is exactly when oil coking quietly starts.

If you’re not controlling oil flow and pressure across those hot-side bearings, you’re inviting varnish, hard coke, and accelerated wear.

Pump 40182032 attacks this problem by keeping oil moving, pressurized, and cooling through the turbo core-but how it does that, and what it means for your overhaul intervals, is where it gets interesting.

How Oil Coking Damages Locomotive Turbochargers

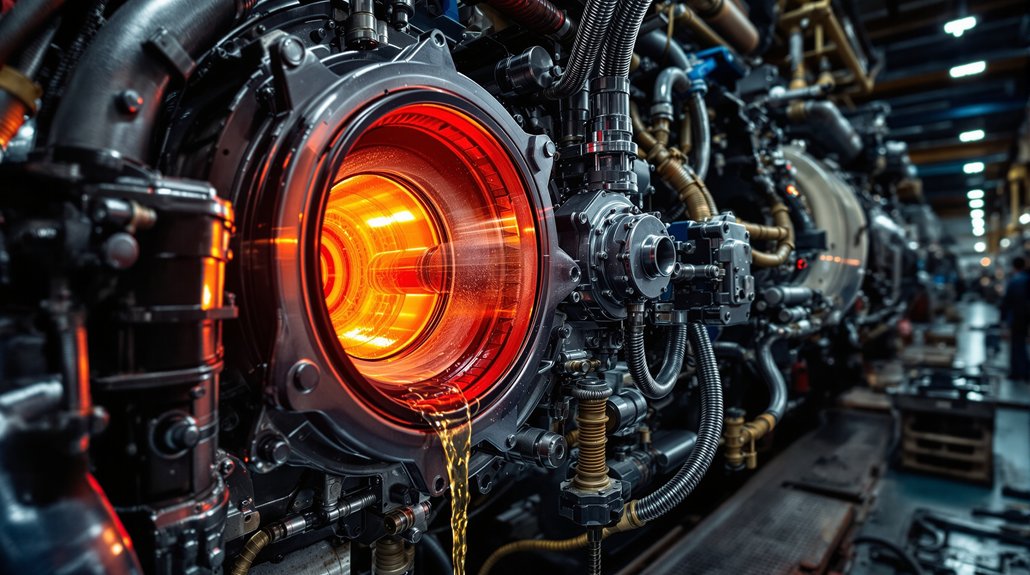

Although modern locomotive turbochargers are designed for extreme duty, oil coking remains one of the most destructive failure modes because it directly attacks the bearing system at its hottest point. At turbine-end metal temperatures of 450-650°C, any residual oil that’s not actively circulating oxidizes rapidly and polymerizes into varnish, then hard carbonized coke. You see the first effects as subtle journal scoring and darkened oil films in the bearing housing.

As deposits build, they narrow feed and drain passages, so even with “normal” system pressure you’re running localized starvation at shaft speeds up to ~300,000 rpm. The bearing oil film collapses, metal-to-metal contact increases, and you move quickly from elevated vibration to full bearing seizure. Coke particles themselves act as abrasives, further eroding journals and thrust faces. With each thermal cycle and each hour on aged or contaminated oil, coke thickness grows, accelerating imbalance, shaft runout, and ultimately catastrophic turbocharger failure.

Shutdown and Soak-Back: When Coking Hits Hardest

Once you shut the engine down after a high-load run, the turbocharger instantly loses pressurized oil flow while turbine-end metal temperatures often remain in the 450–650°C range, creating the most coking-prone moment in the duty cycle. You’ve entered the hot soak phase: bearings sit surrounded by residual oil that can’t escape and can’t cool. With no cooldown flow, that trapped oil dwells at extreme temperature, oxidizes, and solidifies into coke.

During repeated stop/start operation, this thermal pulse becomes a cumulative failure driver. Each shutdown bakes a thin layer of oil into varnish and carbon, progressively:

- Narrowing feed and return passages

- Distorting hydrodynamic film thickness at the shaft

- Raising startup friction and wear

In locomotive service, long high-load pulls followed by shutdown maximize soak-back heat. If you don’t manage that interval, you effectively turn every stop into a controlled coking cycle inside the turbocharger.

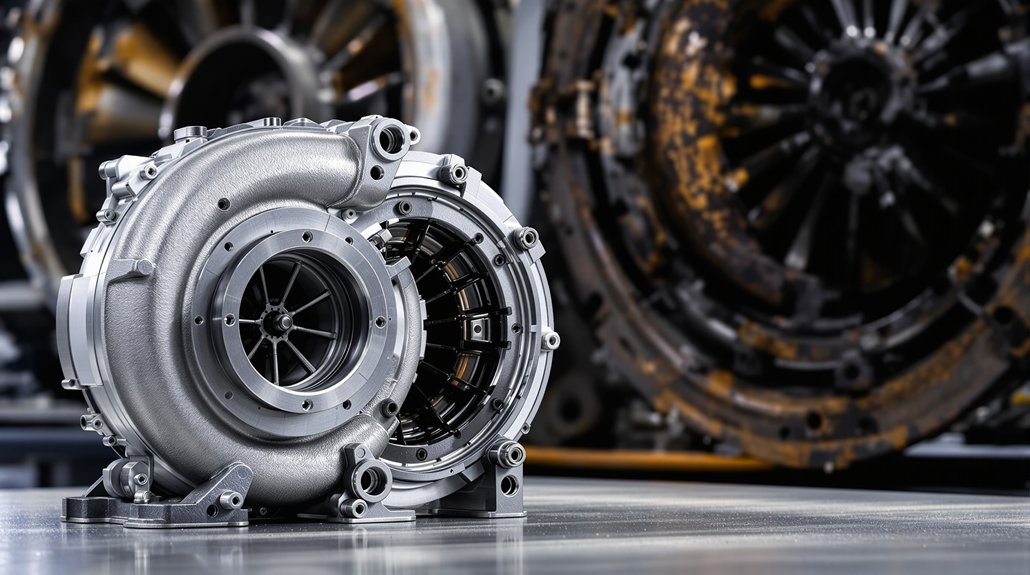

How Turbo Soak Back Pump 40182032 Prevents Oil Coking

In practical terms, Turbo Soak Back Pump 40182032 breaks the coking cycle by keeping oil moving through the turbocharger exactly when it would otherwise sit and burn. After shutdown, it continues to circulate engine oil across the hot-side bearings and oil passages, evacuating heat from the turbine housing and preventing stagnant oil pockets where thermal breakdown accelerates.

You maintain controlled post‑shutdown oil pressure, so bearing surfaces stay fully wetted and protected. Peak oil film temperature drops, slowing oxidation, varnish, and hard coke formation. That directly reduces abrasive deposits on the high‑speed shaft and avoids oil‑starvation events that cascade into bearing failure.

Because the unit’s brushless drive and liquid‑cooled electronics are designed for frequent start/stop operation, you get consistent soak‑back performance over long service intervals. Integrated pre‑lube capability builds an oil film before crank‑over, minimizing dry‑start wear. With proper coolant interaction management and scheduled electrical diagnostics, you keep this anti‑coking control loop stable and predictable.

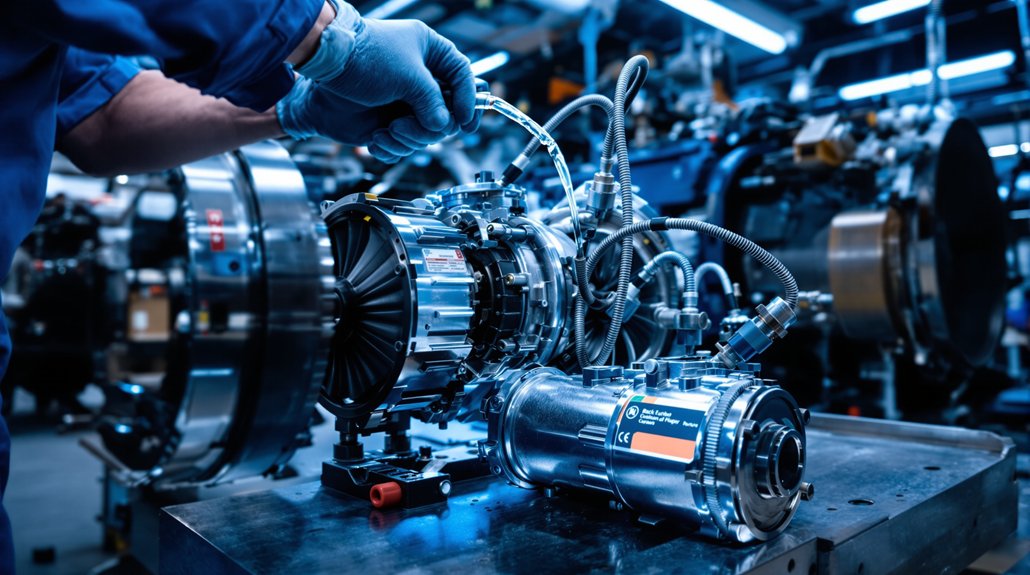

Inside Pump 40182032: Design That Protects Your Turbo

Built around a brushless-induction, liquid‑cooled DC drive, Pump 40182032 is engineered as a dedicated post‑shutdown oil mover that protects your turbocharger when thermal stress is highest. You get a controlled 13 LPM (3.5 GPM) at 2.8 bar (40 PSI), keeping turbo bearings under positive pressure while the housing heat‑soaks. Integrated cooling channels in the pump housing and electronics pull heat away from the drive, preventing thermal drift and extending component life under repeated shutdown cycles.

Internally, hardened gear materials and a reinforced pump body resist scoring from contaminated oil and high differential pressures. Continuously lubricated, self‑cleaning bearings maintain alignment, so you hold flow and pressure without constant adjustments or rebuilds. The same architecture doubles as a pre‑lube system, restoring oil to the turbo before shaft speed rises.

- Maintain predictable cooldown oil pressure every shutdown

- Minimize internal wear over 10‑year heavy‑duty duty cycles

- Reduce unplanned turbo and pump maintenance interventions

Installing and Operating the Turbo Soak Back Pump Safely

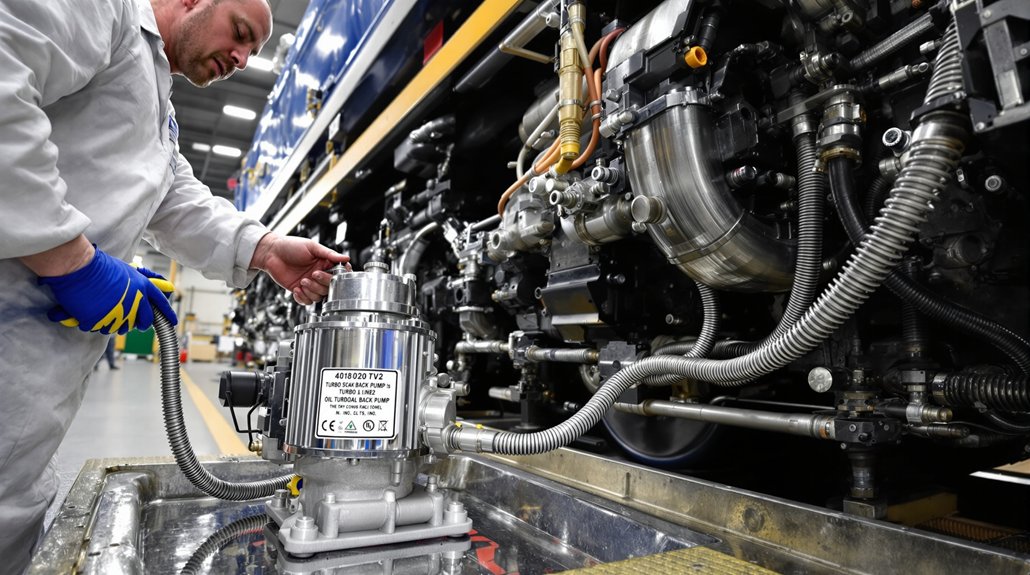

Although Pump 40182032 is designed for unattended reliability, safe installation and operation depend on how precisely you integrate it into the turbo oil and electrical systems. Mount the pump in the turbo oil return or sump feed line exactly per the routing schematic, and confirm the part number and rating: 13 LPM (3.5 GPM) at 2.8 bar (40 PSI) for the 74 VDC AESS model. Any oil pan modifications must use OEM sealing, torque, and cleanliness controls.

Treat electrical routing as a reliability variable: use the specified 74 VDC input, segregate harnesses from exhaust and hot manifolds, and secure all terminations to withstand vibration and contamination.

Validate coolant plumbing to the electronics section for leak-free liquid cooling, then confirm motor orientation and access clearances. Program post-shutdown and pre-lube run times, and verify approximately 13 LPM at 2.8 bar during tests. Finally, implement periodic inspections of lines, fittings, and housing for wear and contamination.

Turbocharger Reliability, Maintenance Savings, and ROI With Pump 40182032

Drive turbocharger reliability higher by attacking one of its primary failure modes: oil coking during hot soak. By keeping oil circulating at roughly 3.5 GPM and ~40 PSI after shutdown, Pump 40182032 flushes hot-side passages, limits varnish and carbon, and protects shaft and bearing surfaces. You cut unplanned turbo replacements, stabilize fuel efficiency by preserving turbo performance, and reduce warranty implications from coked, oil-starved failures.

- Extend turbocharger service life and overhaul intervals by minimizing coke-driven bearing and shaft damage.

- Reduce labor and parts costs tied to turbo swaps, oil-line cleaning, and repeat post-failure inspections.

- Protect assets in frequent start/stop AESS duty cycles where hot-soak events multiply.

The brushless induction motor, liquid-cooled electronics, and hardened internals target a maintenance-free life approaching 10 years. That durability turns a one-time capital outlay into predictable ROI, anchored in avoided turbo failures, fewer warranty disputes, and higher locomotive availability.

Frequently Asked Questions

How to Prevent Turbo Coking?

You prevent turbo coking by controlling heat and oil chemistry. Since deposits can cut bearing life by over 50%, you must manage idle heating: after high load, idle a few minutes so metal temps drop below coke-forming ranges. Use strict additive selection—high-oxidation-stability synthetic oils, boosted detergents, and dispersants. Maintain clean feed/return lines, enforce short oil-change intervals under severe duty, and verify post-shutdown oil circulation performance.

How Do Scavenge Pumps Work?

You use scavenge pumps to pull hot oil away from bearings and return it to the dry sump before it degrades. A rotary scavenge stage runs under slight vacuum at the turbo outlet, rapidly evacuating oil and entrained air. You size the pump for several L/min flow so residual volume stays low. This controlled extraction reduces dwell time, prevents coking, and stabilizes bearing temperatures and oil film thickness.

What Causes Oil in a Turbocharger?

You get oil in a turbocharger because the engine’s pressurized lube circuit feeds the turbo bearings for cooling and friction control. At turbine-side temperatures approaching 650°C, you’re fighting thermal degradation and oil contamination from oxidized films and fine wear metals. Any seal wear, housing distortion, or drain restriction lets that oil leak into the compressor or turbine housings, where it burns, forms deposits, and undermines long-term reliability.

Does a Turbo Pump Its Own Oil?

No, a turbo doesn’t pump its own oil; you rely on the engine’s lube system for shaft lubrication and cooling. The engine oil pump provides pressure regulation and flow through the turbo’s feed gallery, then oil drains back to the sump by gravity. When the engine stops, circulation ceases, so you must manage shutdown and auxiliary systems carefully to avoid stagnant hot oil, varnish, and bearing damage.