The EMD 710 engine is a powerful and dependable diesel engine used in a multitude of locomotive and marine applications. EMD®, or Electro-Motive Diesel, is a leading manufacturer known for its high-quality products and innovative designs, often setting the standard in the locomotive industry. This article provides a comprehensive overview of EMD 710 engine bearings, critical components that ensure the smooth and efficient operation of these engines.

Overview of EMD Locomotive Components

EMD locomotive parts encompass a vast range of components, forming complex systems integral to the locomotive’s function. These parts include everything from the engine itself to the generator, alternator, and even the turbochargers. The 710 engine is just one model in EMD’s lineup, preceded by the 567 and 645 and followed by later generations.

Introduction to EMD and Its Importance in Locomotives

EMD stands as a cornerstone in the rail equipment and locomotive industry. EMD locomotives have long been the workhorse of railways across the globe, often compared with ALCO models for their reliability. Their diesel engine designs, particularly the 710 engines, provide significant power for moving heavy loads. The EMD locomotive is an icon, integrating innovation and standard configurations to meet the demanding needs of the railway, mining, and industrial markets.

Understanding EMD Bearings and Their Functions

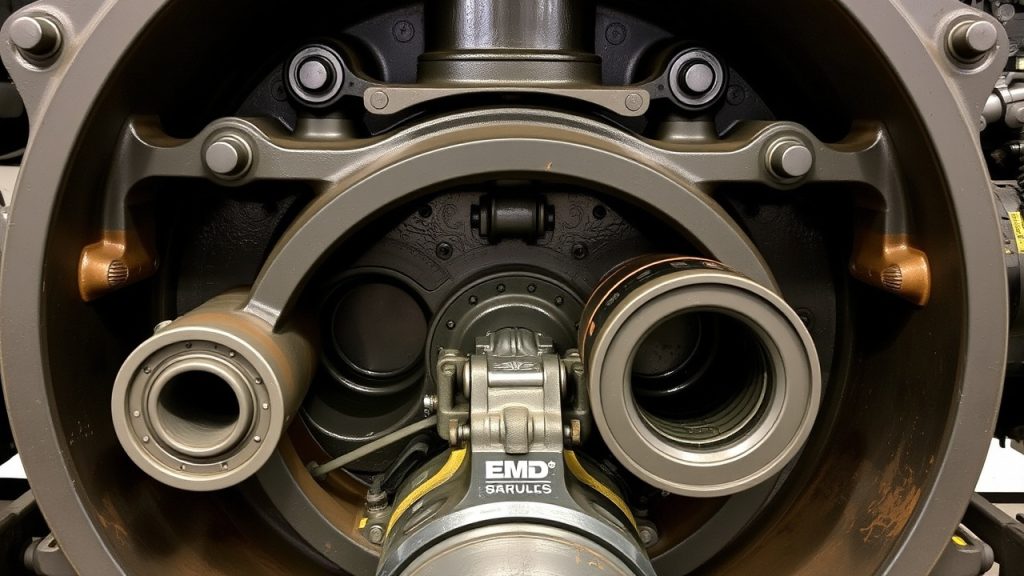

EMD bearings are crucial components within the engine, specifically designed to handle immense loads and torque. These bearings support rotating parts, minimizing friction and wear, and are essential for maintaining the engine’s performance and longevity. An EMD bearing is a vital locomotive part that ensures the dependable operation of the entire unit.

Key Components of EMD Locomotive Parts

Beyond the engine itself, EMD locomotive parts include essential components like valves, turbo units, alternators, and electric systems, all of which require rigorous testing to ensure reliability. These components work in concert to deliver power. The interaction of these locomotive parts influences the efficiency and reliability of the entire system. Replacement part options are available in both OEM quality and aftermarket.

Types of EMD Bearings

Main Bearings for EMD 710 Engines

The main bearings within EMD 710 engines are critical engine parts, as they support the crankshaft, which is the core of the engine, handling the substantial torque generated during the diesel combustion process. These EMD bearings are designed to withstand heavy loads and ensure the smooth rotation of the crankshaft, helping maintain the power output of the engine. Maintenance and timely replacement of these bearings are vital to prevent engine failure. These are locomotive parts that must be in perfect working order.

Valve Bearings and Their Role in Engine Performance

Valve bearings, or valve train components, in EMD 710 engines play a vital role in ensuring proper valve operation. Valves control the intake of air and exhaust of gases, thus optimizing engine performance. These EMD bearings help in reducing friction and wear in the valve mechanism, improving the efficiency and longevity of the engine. The right valve bearings are a locomotive part that ensures the proper functioning of the diesel engine. They also provide optimal sealing and are an integral part of the overall diesel engine assembly.

Comparison of Aftermarket vs. OEM EMD Bearings

When it comes to EMD bearings, the market offers both OEM quality and aftermarket options. OEM EMD bearings are manufactured by EMD® or its certified suppliers, guaranteeing compatibility and performance. Aftermarket EMD bearings, on the other hand, are supplied by third-party manufacturers, which may not always meet the same testing standards as OEM parts. Aftermarket parts may offer cost savings but can vary in quality and durability. When choosing EMD locomotive parts, consider the application, budget, and the criticality of the component; in this case, the bearing, which should be in stock for timely replacement. Genuine OEM parts are always best.

Applications of EMD Locomotive Parts

Utilization in Diesel Electric Locomotives

EMD locomotive parts are extensively used in diesel electric locomotives across various railway systems. These EMD locomotive parts, including the EMD 710 engines, provide the essential power for hauling heavy loads over long distances. The reliability and performance of these components are critical for maintaining efficient railway operations. Because of the demands of the application, the railway is where these locomotives are the most effective.

Role in Marine Engine Applications

Beyond the railway, EMD 710 engines and their respective parts, including EMD bearings, also find applications in marine environments. These diesel engines are used to power ships and boats, providing reliable power for propulsion and other onboard systems. In marine applications, the durability and resistance to corrosion of the EMD parts are essential to withstand harsh conditions. Marine applications are the perfect example of a location where the EMD parts can be implemented.

Performance in Mining and Heavy-Duty Use

EMD locomotive parts, designed for robust performance, are also employed in mining and other heavy-duty industrial applications. EMD 710 engines are adapted to power heavy machinery, providing the necessary torque and reliability for demanding tasks. The mining industry relies on the dependable performance of EMD engines and their components, including standard configurations, to maintain productivity. The design of these engines and parts are compatible with the challenges that arise in the mining industry.

Maintenance and Repair of EMD Bearings

Signs of Wear and Replacement Indicators

Early detection of wear in EMD bearings is key for proactive maintenance. Several indicators can signal a potential issue. These include:

- Unusual noises, increased vibrations, or elevated temperatures around the bearing housings.

- Excessive play or looseness in the bearings.

Visual inspection might reveal cracks, pitting, or discoloration, all suggesting the need for bearing replacement to avoid major engine failure and ensure that spare parts are readily available. Ignoring these indicators can lead to catastrophic damage to the EMD 710 engines and other locomotive parts, highlighting the importance of regular testing and maintenance.

Best Practices for EMD Bearing Maintenance

Effective EMD bearing maintenance involves implementing a strict schedule of inspections and lubrication. Using the appropriate lubricants, as specified by EMD®, is essential for reducing friction and wear. Keeping the bearing clean and free from contaminants is also vital. Regular monitoring of bearing temperature and vibration levels can help identify potential issues early. Properly maintained EMD bearings contribute to the longevity and reliable performance of EMD 710 engines. The OEM recommends using a quality lubricant to ensure maximum life of the EMD bearings. A genuine component is best to keep the EMD engine running smoothly, ensuring it meets the required standards for performance.

Repair Techniques for EMD Locomotive Components

When EMD locomotive components, including bearings, require repair, specific techniques must be employed. Minor repairs might involve cleaning, polishing, or re-lubricating the bearing to maintain standard performance levels. However, severely damaged bearings must be replaced. Proper installation techniques, including correct torque settings and alignment, are critical to ensure optimal performance and prevent premature failure of components in the configuration.. Specialized tools and trained technicians are often required for complex repairs of EMD 710 engines and related locomotive parts.

Suppliers and Availability of EMD Parts

Identifying Reliable Suppliers for EMD Bearings

Securing EMD bearings from reliable suppliers is paramount for ensuring quality and dependability. It’s important to look for specific characteristics in your suppliers, such as:

- Proven track record of providing OEM quality parts.

- A warranty on their products and excellent customer service.

It is also important to verify that the EMD 710 engines’ parts from the supplier can handle the torque that the locomotive may output, as some may not be rated for industrial use.

Trusted suppliers like Mikura International are preferred over many local vendors.

Overview of Supply Chain for EMD Locomotive Parts

The supply chain for EMD locomotive parts involves a network of manufacturers, distributors, and service providers. EMD® itself manufactures many critical components, while other parts are sourced from certified suppliers. Distributors play a key role in making these parts available to railway operators and maintenance facilities. Understanding the supply chain helps in identifying potential bottlenecks and ensuring timely availability of replacement parts. The quality of the parts supplied will keep the engine running.

Future Trends in EMD Component Supply

Future trends in EMD component supply are likely to focus on improved efficiency, sustainability, and technology, with an emphasis on stock management of critical parts. There is a growing emphasis on remanufacturing and recycling of EMD parts to reduce waste and environmental impact. Advanced materials and manufacturing techniques are being used to produce more durable and efficient components, setting a new standard in the industry. Digital technologies, such as predictive maintenance and online parts catalogs, are also transforming the EMD parts supply chain by optimizing spare parts management. A dependable supply of EMD 710 engines’ parts will allow the user to keep the equipment in operation.

Q: What types of engine parts are included in the EMD 710 engine bearings product line?

A: The EMD 710 engine bearings product line encompasses a comprehensive range of components that are crucial for the optimal performance of EMD® engines. This includes not only main bearings, which are essential for supporting the crankshaft and ensuring smooth operation, but also connecting rod bearings that play a vital role in enabling the connection between the crankshaft and the engine’s pistons.

Additionally, turbocharger bearings are included in this product line, designed specifically to withstand the high temperatures and pressures associated with turbocharged engine applications. Together, these components are engineered to meet the rigorous demands of EMD locomotives, ensuring reliability and efficiency in various operational conditions.

Q: Are EMD 710 engine bearings compatible with GE generator systems?

A: Yes, EMD 710 engine bearings are compatible with certain GE generator systems, provided they meet the specifications for the engine assembly. This compatibility is crucial for ensuring optimal performance and longevity of the coupling bushings in EMD locomotives’ main generator systems.

Proper alignment and adherence to the specified tolerances are essential to prevent premature wear and maintain efficient operation. When integrating EMD 710 engine bearings into GE generator systems, it is important to consult detailed engineering documentation to ensure that all components work seamlessly together, thereby enhancing the overall reliability and functionality of the locomotive’s power generation capabilities.

Q: What is the power output of the EMD 710 engine compared to the EMD 645 and 567 engines?

A: The EMD 710 engine is renowned for its superior power output compared to its predecessors, the EMD 645 and 567 engines. This enhanced performance makes the EMD 710 the preferred choice for various applications that demand more robust and reliable operation. Whether in freight locomotives or other heavy-duty machinery, the increased efficiency and power of the EMD 710 engine ensure that it meets the rigorous demands of modern transportation and industrial needs.

Q: Where can I find replacement bearings for the EMD 710 engine assembly?

A: Replacement bearings for the EMD 710 engine assembly are available through authorized EMD® distributors and various online retailers specializing in locomotive and marine parts.

Q: Do EMD 710 engine bearings come with a warranty?

A: Yes, most EMD 710 engine bearings come with a manufacturer’s warranty, which covers defects in materials and workmanship under normal operating conditions.

Q: What maintenance is required for the EMD 710 engine bearings and other engine parts?

A: Regular maintenance for EMD 710 engine bearings includes routine inspections, proper lubrication, and ensuring that the engine operates within the recommended temperature and pressure ranges.

Q: Can I use EMD 710 engine bearings in marine applications?

A: Yes, EMD 710 engine bearings are suitable for marine applications, particularly in vessels that require high-performance engine components for reliability and efficiency.

Q: What are the key features of EMD 710 engine bearings that enhance performance?

A: Key features of EMD 710 engine bearings include advanced materials for durability, precision manufacturing for optimal fit, and designs that reduce friction and wear, enhancing overall engine performance.

Q: Are there any specific tools required for the installation of EMD 710 engine bearings?

A: Yes, proper installation of EMD 710 engine bearings may require specific tools such as torque wrenches, bearing pullers, and alignment tools to ensure accurate assembly and operation.

You may also like to read: EMD-Bearing Inspection and Qualification of Engine Main Bearings