The 26C WABCO brake system stands as a cornerstone of modern locomotive technology, ensuring the safe and efficient operation of trains. This comprehensive guide delves into the intricacies of the 26C WABCO air brake valve, a critical component responsible for controlling the air brake functionality of the entire train. Proper service and control of this valve is paramount to maintaining the integrity of the train’s braking system and ensuring the safety of both the train crew and the freight it carries. Mikura International, a top exporter of locomotive and marine engine parts, understands the critical nature of these systems and provides high-quality components for maintaining and repairing them.

Understanding the 26C WABCO Air Brake System

Overview of Air Brake Functionality

Air brake functionality in a locomotive is essential for both routine stopping and emergency situations. The system relies on compressed air, stored in reservoirs, to apply pressure to the train brakes. When the engineer operates the 26C brake valve, it either allows air into the brake pipe to release the train brakes or vents air from the brake pipe to apply them.

The reduction of brake pipe pressure signals the control valves on each car to apply the brakes proportionally. The effectiveness of the air brake depends on several factors, including brake pipe pressure, the condition of the brake equipment, and the proper functioning of the 26C valve itself. This functionality ensures controlled deceleration and prevents uncontrolled train movement, which is particularly crucial in freight operations.

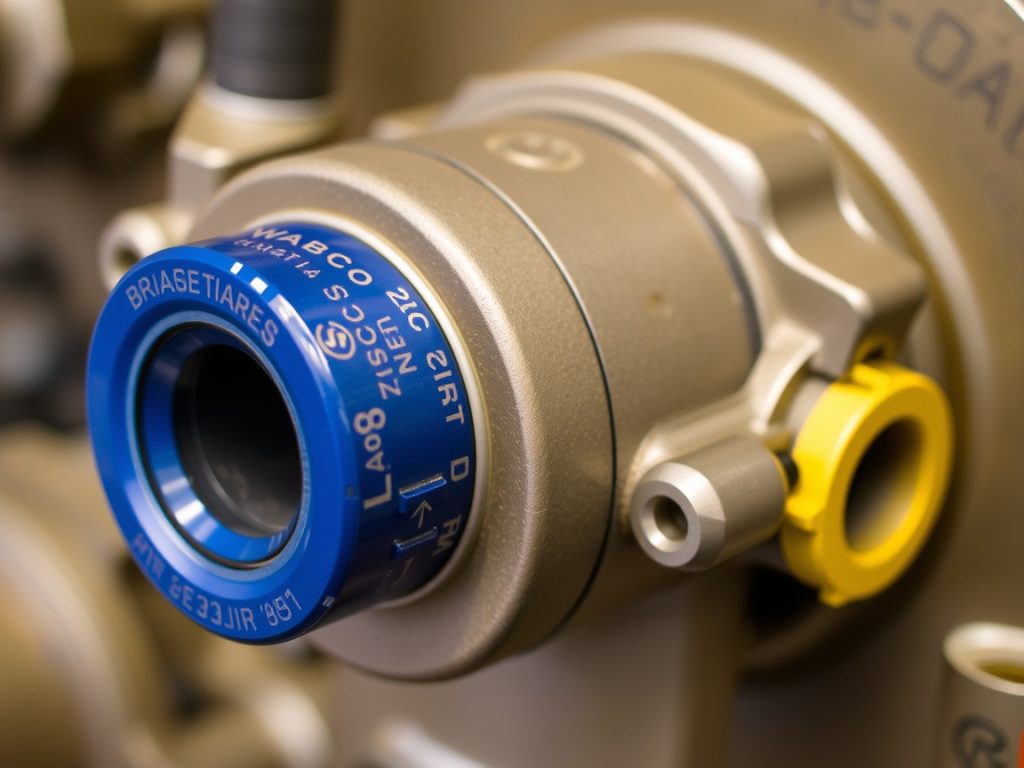

Key Components of the 26C Brake Valve

The 26C brake valve comprises several key components that work in harmony to control the air brake system. These include slide valves that regulate the flow of air, a feed valve to maintain brake pipe pressure, and various check valves that prevent backflow and ensure proper function. The main reservoir provides a constant supply of compressed air, while the brake pipe serves as the trainline, transmitting pressure changes to each car. Understanding the function of each component is crucial for effective service and troubleshooting. The 26C valve controls both the automatic and independent brake systems, providing the engineer with comprehensive control over the train brakes. These components must function correctly to ensure that the brake valve operates safely and reliably.

Importance of Proper Brake Control

Proper brake control is fundamental to the safe and efficient operation of any train equipped with the 26C WABCO brake system. The engineer must be able to precisely apply and release the train brakes to maintain speed, navigate curves, and respond to unexpected situations. This control depends on the correct functioning of the 26C brake valve and the entire air brake system.

A malfunctioning valve can lead to unpredictable brake application, potentially causing derailments or collisions. Therefore, regular service and maintenance of the 26C valve is essential. By ensuring the brake equipment is in optimal condition, we prevent issues such as unintended emergency application or a failure to release brakes effectively. The ability to apply first service, full service, and manage reduction of pressure safely is key to preventing accidents.

Maintenance and Service of the 26C Brake Valve

Regular Inspection Guidelines

Regular inspections are paramount to maintaining the functionality and reliability of the 26C WABCO brake valve. These inspections should be performed on a scheduled basis, considering the service hours and operating conditions of the locomotive. During inspection, pay close attention to any signs of air leaks around the 26C brake valve, which can indicate worn seals or loose connections.

Check the position of the 26C valve handle to ensure it aligns correctly with the indicated operating modes. Verify the integrity of the brake pipe pressure by observing gauges and comparing them to the expected values in each position. Also, ensure that all control valves are functioning as designed. Mikura International recommends regular inspections to help prevent major failures and extend the lifespan of your brake equipment.

Common Issues and Troubleshooting

Several common issues can arise with the 26C WABCO air brake valve, affecting its performance and safety. One frequent problem is the sticking of slide valves, which can lead to delayed or incomplete brake application or release. Contamination within the air system can cause these valves to malfunction.

Another issue is the failure of the feed valve to maintain correct brake pipe pressure, resulting in inconsistent braking performance. Air leaks, often caused by worn or damaged seals, can also reduce the efficiency of the air brake system. For troubleshooting, use a systematic approach, starting with visual inspections and air pressure tests. If you encounter these problems, Mikura International offers rebuild kits and replacement parts to restore your brake valve to optimal condition.

Step-by-Step Service Procedures

Here’s how to service the 26C WABCO brake valve, taking a careful, step-by-step approach. First, isolate the valve and relieve all pressure. Then, you’ll need to perform several crucial actions:

- Disassemble the 26C valve, carefully noting the orientation of each component, and clean all parts thoroughly with appropriate solvents, paying close attention to slide valves and seats.

- Inspect each component for wear or damage, replacing any questionable parts with new ones from Mikura International to ensure optimal function.

- Reassemble the valve, lubricating moving parts with approved lubricants.

- Test the valve to ensure proper operation and calibration, verifying that it functions correctly in all positions, including release, running, and emergency application.

- Adjust the valve to maintain correct brake pipe pressure.

This ensures reliable control and prevents issues such as unintended service brake application.

Expert Insights on Air Brake Performance

Enhancing Brake Efficiency

To enhance brake efficiency in locomotives equipped with the 26C WABCO air brake system, several key strategies can be implemented. Regularly inspect and service the brake valve to ensure all components, including the slide valves and check valve, are functioning correctly. Maintaining proper brake pipe pressure is crucial, so ensure the feed valve is calibrated accurately.

Optimize the brake equipment by using high-quality replacement parts from Mikura International, a top exporter, ensuring each part fits and operates within specified tolerances. Consider upgrading to a newer version or feature of the 26C brake system if available, as newer models often incorporate improvements in air flow and control. Addressing these aspects helps maintain optimal performance, prevent issues like unintended brake application, and enhances the overall reliability of the air brake system. Ensuring that the engineer can apply the train brakes effectively is fundamental to safe train operation.

Real-World Case Studies

Examining real-world case studies provides valuable insights into the performance and troubleshooting of the 26C WABCO air brake system. Consider a case where a freight train experienced inconsistent brake application due to a malfunctioning feed valve. Replacing the valve with a high-quality component from Mikura International restored consistent brake pipe pressure and resolved the issue.

Another case involved a road locomotive with excessive air loss, traced to worn seals in the 26C brake valve. A complete rebuild, using Mikura International rebuild kit, eliminated the air leaks and improved the overall brake efficiency. These examples underscore the importance of regular service and using quality parts to maintain the integrity of the brake equipment. Such practical scenarios offer guidance on addressing common problems and optimizing the performance of the air brake system on the engine.

Innovative Solutions for Common Problems

Innovative solutions are continually being developed to address common problems encountered with the 26C WABCO air brake system. One approach is to implement advanced diagnostic tools that can detect subtle air leaks or valve malfunctions before they escalate into major issues. Another solution involves using improved filtration systems to prevent contaminants from entering the air system and causing damage to the slide valves and other critical components.

Mikura International offers upgraded versions of certain parts, designed with enhanced materials and improved designs to prolong service life. For instance, using new generation of control valves that are more resistant to wear and tear. Additionally, consider incorporating automatic drain valves to remove moisture from the air reservoirs, preventing corrosion and ensuring the brake valve operates smoothly and correctly. Addressing these issues head-on with innovative solutions can significantly improve the reliability and efficiency of the locomotive air brake system, maintaining proper brake pipe pressure and preventing unexpected emergencies during first service or full service application.

Best Practices for Locomotive Brake Control

Training for Operators and Technicians

Comprehensive training programs are essential for locomotive operators and technicians to ensure the safe and efficient operation of the 26C WABCO air brake system. Operators must be thoroughly trained on the 26C brake valve’s function and how to correctly operate it in various situations, including first service, full service, and emergency application. Technicians need in-depth knowledge of the valve’s components, maintenance procedures, and troubleshooting techniques.

Training should cover the importance of maintaining proper brake pipe pressure and the consequences of malfunctioning brake equipment. Practical exercises and simulations can help reinforce theoretical knowledge and build confidence in handling different scenarios. Furthermore, training must emphasize the importance of regular service and inspection to prevent issues that could compromise safety. The goal is to ensure all personnel are capable of safely operating and maintaining the air brake system. Properly trained engineers can minimize the risk of unintended application of the train brakes or failure to release them, ensuring smooth and safe railroad discussion.

Implementing Safety Protocols

Implementing robust safety protocols is crucial for maximizing the reliability and safety of the locomotive air brake system, especially concerning the 26C WABCO brake valve. Regular inspections and maintenance schedules are the cornerstone of these protocols, ensuring that all components are functioning correctly. These protocols should specify the frequency and scope of inspections, detailing what to check for, such as air leaks, worn parts, and proper valve operation. It’s vital to implement a system for reporting and addressing any issues identified during inspections promptly.

Operators should be trained to recognize warning signs of potential problems, such as unusual brake application behavior or inconsistent brake pipe pressure, and to take appropriate action, including reporting the issue and, if necessary, stopping the train. These safety protocols prevent major malfunctions and ensure the safety of the train and its crew. Proper maintenance of the brake equipment and rigorous adherence to safety guidelines are essential for the safe and efficient operation of locomotives. Maintaining proper brake pipe pressure is essential, and a malfunctioning feed valve could lead to catastrophic events. The safety protocols should prevent such events during first service or full service.

Future Trends in Brake Technology

The future of brake technology for locomotives is focused on enhancing safety, efficiency, and reliability of the air brake system. One significant trend is the integration of advanced electronic control systems, which can provide more precise control over brake application and release. These systems often incorporate features such as automatic brake blending, which optimizes the use of both the air brake and dynamic brake to reduce wear and improve stopping performance. Another trend is the development of more durable and reliable brake valve components, such as slide valves and seals, that can withstand the rigors of heavy use and extreme conditions.

Additionally, research is underway to develop brake systems that are more resistant to contamination and corrosion, reducing the need for maintenance and extending service life. Advanced sensor technology is also being integrated to continuously monitor brake pipe pressure and system performance, providing early warnings of potential issues. These advancements ensure that the brake equipment maintains the highest level of safety and efficiency, providing engineers the reliable control needed for safe train operation. Future versions of the 26C WABCO brake valve may feature improved materials and designs to enhance its performance and longevity. Automatic train control (ATC) systems also integrate with brake systems to prevent accidents.

Q: What is the function of the 26C WABCO brake in electric locomotives?

A: The 26C WABCO brake is designed to control the air brake system in electric locomotives, ensuring effective braking through proper charge distribution and pressure management.

Q: How do you adjust the release position on a 26C WABCO brake?

A: To adjust the release position on a 26C WABCO brake, ensure the system is in the running position, then calibrate the settings according to the manufacturer’s specifications to achieve the desired pressure for a smooth release.

Q: What does it mean when the 26C WABCO brake drops pressure unexpectedly?

A: An unexpected drop in pressure can indicate a malfunction within the brake system, such as a leak or failure in the distribution system. This issue is critical as it can compromise the overall safety and functionality of the locomotive’s braking system. To ensure the reliability and performance of the brakes, it is essential to conduct immediate inspection and servicing whenever a pressure drop is detected. Addressing these problems promptly can prevent further damage and ensure the locomotive operates safely and efficiently.

Q: How can you troubleshoot a big hole problem in a 26C WABCO brake?

A: Troubleshooting the WABCO locomotive service brake valve requires careful attention to several components. Begin by examining the 26-c valve, as any choke or blow in the system can lead to significant air loss, often measured in lbs. The 24-rl model may also need inspection for proper operation. Ensure that the bracket holding the valve is secure and that the connections are tight to prevent leaks. Additionally, verify the performance of the 8-el and 6-et valves to maintain the recommended pressure levels and avoid issues that could arise from a big hole problem.

Q: What are the key components of the 26C WABCO air brake system?

A: Key components of the 26C WABCO air brake system include the charge valve, lap valve, release valve, and distribution system, each playing a crucial role in the effective operation of the braking system.

Q: How does the lap function work in the 26C WABCO brake?

A: The 26C WABCO locomotive service brake valve features a lap function that plays a crucial role in maintaining brake pressure, effectively preventing any unintended release of the air brake system. This control mechanism ensures that the brake valve remains in a position that keeps the train brakes engaged until the engineer applies a deliberate action to release them.

By managing the brake pipe pressure and utilizing the correct operation of control valves, the system can adapt to various situations, including emergency applications, without compromising safety. Proper maintenance of the brake equipment, including the check valve and feed valve, is essential to prevent issues such as a drop in pressure that could lead to a “big hole” scenario. Additionally, understanding the function of the independent and automatic brake systems allows for effective troubleshooting and ensures optimal performance of the locomotive’s braking capabilities, especially in freight and road locomotives.

Q: What should you do if the 26C WABCO brake does not respond to throttle commands?

A: When troubleshooting the WABCO locomotive service brake valve, it is essential to ensure that the air brake system is operating correctly. Begin by checking the brake pipe pressure and verifying the positions of the control valves. The control features of the 26C version should be inspected for any faults, particularly focusing on the release position and the function of the check valve.

If the train brakes do not respond, inspect the main reservoir and ensure it is properly charged. Additionally, the feed valve and slide valves should be examined to prevent any reduction in braking performance. A thorough discussion on the operation of the brake equipment is crucial for maintaining safety on freight and passenger trains, especially in emergency applications where every pound of pressure counts.

Q: How often should the 26C WABCO brake system be serviced?

A: The 26C WABCO brake system should be serviced regularly, typically every 1,000 miles of operation or as recommended by the manufacturer, to ensure reliability and safety.

Q: What is the significance of the 14-EL and 8-ET valves in the 26C WABCO brake?

A: The 14-EL and 8-ET valves are critical components that help regulate the air flow and pressure within the 26C WABCO brake system, ensuring proper operation and responsiveness during braking.