Unexpected engine failure from aftercooler defects is costly and risky. Operators face breakdowns, downtime, and reliability loss on critical rail schedules. Moisture, corrosion, and mechanical failures drive most issues. The right maintenance can prevent many failure modes. Use this guide to identify weak points early and protect efficiency and longevity in diesel locomotives.

For reliable cooler performance and longevity, follow a consistent inspection and maintenance routine. Key practices include:

- Inspect for leaks at tubes, seals, and caps weekly.

- Track temperature deltas across the cooler under load.

- Check for condensation on the air side after shutdowns.

- Test sealing surfaces and grooves for pitting and fatigue.

- Monitor pressure drop to spot fouling and blockage.

- Verify alloy compatibility with condensate chemistry.

- Apply epoxy coatings where corrosion risk is high.

- Torque aluminum housing fasteners to spec after thermal cycles.

- Sample condensate for copper, aluminum, and stainless ions.

- Keep a repair kit with seals, caps, and approved cleaners.

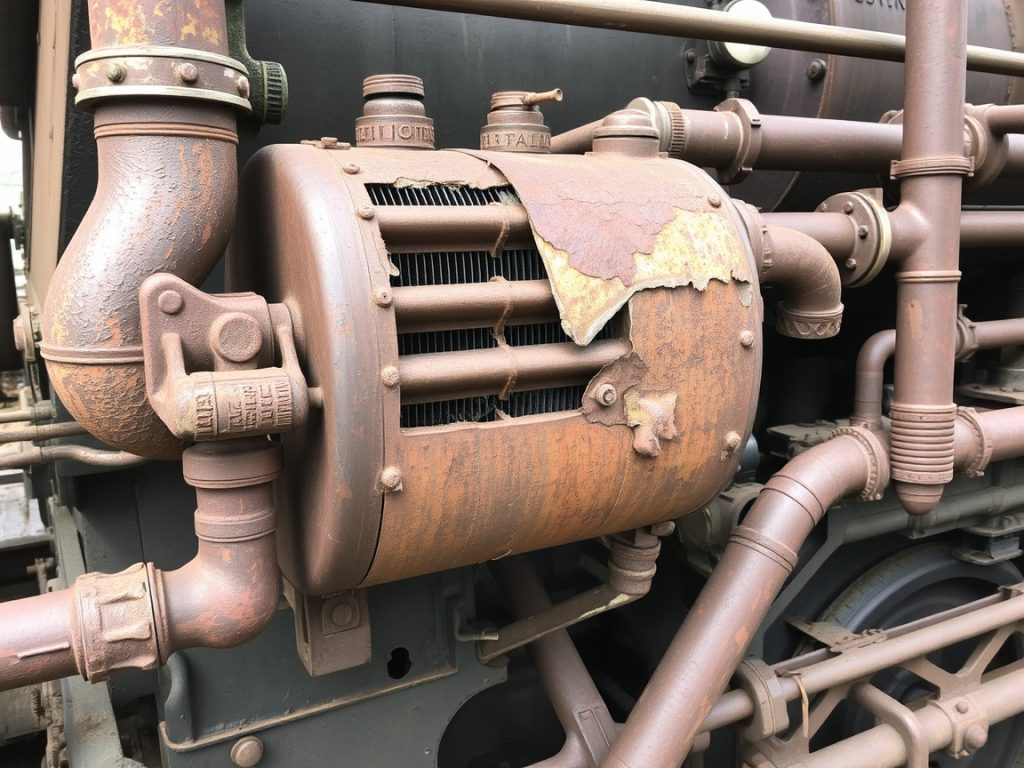

Understanding Aftercoolers in Locomotive Engines

Aftercoolers are heat exchangers that cool compressed charge air before combustion in a diesel engine. In a locomotive, this component stabilizes temperature, raises air density, and improves efficiency. Reduced intake temperature prevents knock-like events and protects the assembly from thermal expansion stress. Proper maintenance keeps the housing, tube bundle, and seal set reliable. Engineers and mechanics must prevent condensate pooling, manage corrosion, and confirm the cooler’s service readiness to avoid costly downtime on rail routes.

Importance of Aftercoolers in Diesel Engines

Cooler charge air increases oxygen mass, improving combustion and fuel efficiency in diesel locomotives. The aftercooler also cuts exhaust temperature and reduces blow-by by stabilizing cylinder pressure. A reliable cooler helps prevent engine failure from detonation-like pressure spikes. It protects the turbo, valves, and pistons from heat fatigue. Proper maintenance extends longevity of the engine and cooler housing. Operators reduce risk, avoid costly repair, and keep trains on schedule. Mikura International supports parts supply to ensure reliability.

How Aftercoolers Work in Locomotive Systems

Compressed air exits the turbo hot and enters the cooler’s core of tubes within the housing. The heat exchangers transfer heat to coolant, lowering temperature before the air reaches the intake manifold. Expansion and cooling can create condensation on the air side, forming condensate that must drain. If drainage fails, moisture can pit copper or aluminum surfaces and attack seals. Technical controls manage temperature, flow, and pressure. Proper maintenance and correct alloys prevent corrosion, leaks, and mechanical defects that lead to breakdowns and downtime.

Common Mechanical Failures in Locomotive Aftercoolers

Most operators fear sudden engine failure from a defective aftercooler. The risk is costly downtime, lost rail slots, and safety exposure. Moisture, corrosion, and mechanical failures drive many breakdowns. The goal is to prevent failure modes before they escalate. Use the checks below to protect efficiency and longevity and keep service reliable.

To maintain optimal performance and reliability, follow these key maintenance practices for your heat exchanger system. Start by inspecting core components and monitoring operating conditions, then perform targeted checks and preventive actions as needed. Recommended steps include:

- Inspect the housing, tube bundle, and seal set for leaks.

- Track temperature and pressure drop to spot blockage.

- Check sealing surfaces and grooves for pits and fatigue.

- Test caps and fasteners on aluminum housing after cycles.

- Drain condensate to reduce corrosion and moisture damage.

- Verify alloy compatibility: copper, aluminum, stainless.

- Apply epoxy where corrosion risk is high.

- Replace worn components with manufacturer-approved parts.

- Calibrate sensors to avoid false diagnostics.

- Keep a repair kit ready to cut downtime.

Identifying Mechanical Failures

Mechanical failures often begin with small leaks, unusual temperature spreads, and rising pressure drop across the cooler. Look for condensation on the air side after shutdowns, as pooled condensate indicates drainage defects. Inspect tube ends for cracks, pits, and fretting at the sealing surface and groove. Check caps and fasteners on the aluminum housing for torque loss from thermal expansion and fatigue. Listen for hiss under load, which signals a leak near a component joint. Review data trends; step changes reveal failure modes early.

Consequences of Aftercooler Failures

When an aftercooler fails, hot air reaches the diesel engine, reducing charge density and combustion efficiency. The result is power loss, higher exhaust temperature, and increased blow-by. Moisture carryover from condensate can pit copper and stainless tubes and contaminate the intake. Leaks allow unfiltered air, raising wear on cylinders and valves. Severe defects can trigger runaway detonation-like pressure spikes, risking engine failure and costly downtime. Rail schedules slip, repair costs spike, and reliability metrics degrade, exposing operators to service penalties.

Preventive Measures to Avoid Failures

Prevent failures with proper maintenance that targets moisture, corrosion, and mechanical stress. Drain condensate routinely and verify free flow paths. Use compatible alloy pairs and apply epoxy coatings where saltwater exposure or aggressive condensate exists. Retorque aluminum housing fasteners after heat cycles to prevent fatigue loosening. Pressure test the assembly and inspect each tube and seal for wear. Track temperature delta and pressure drop to flag fouling. Use manufacturer-grade components and caps. Mikura International supplies precision parts to restore reliability and extend longevity in locomotive service.

Condensation Issues in Locomotive Aftercoolers

Condensation in a locomotive aftercooler is a silent driver of failure and engine downtime. Moisture pools after shutdown, attacks the tube bundle, and accelerates corrosion. Operators then face costly repair, reduced efficiency, and risk of engine failure on critical rail routes. Tackle the root causes with disciplined maintenance and technical controls that prevent condensate carryover, protect the sealing surface, and extend longevity across service intervals. The goal is simple: keep air cool, dry, and clean so the diesel engine delivers reliable power.

To maintain optimal performance and prevent premature failures, follow these maintenance and inspection practices for your equipment:

- Drain condensate immediately after shutdowns and cold starts.

- Verify free drainage paths and cap vents on the air side.

- Monitor temperature delta to detect hidden moisture risks.

- Inspect tubes, grooves, and seals for pits and fatigue.

- Pressure test the housing to rule out leaks and defects.

- Use compatible alloy pairs to resist corrosion damage.

- Apply epoxy coatings where saltwater aerosols exist.

- Retorque aluminum housing fasteners after heat cycles.

- Log data trends to flag early failure modes.

- Stock a repair kit for rapid service recovery.

How Condensation Affects Aftercoolers

When hot compressed air cools, condensation forms on the air side and collects as condensate. If drainage is poor, the moisture remains in the housing and tube lanes. It causes corrosion on copper, stainless, and aluminum surfaces. Expansion and contraction drive fatigue at each sealing surface and groove. Pitting weakens tubes and raises the chance of a leak. Water carryover into the diesel engine reduces efficiency and promotes failures. Proper maintenance and material selection prevent this costly chain reaction.

Signs of Condensation Problems

Watch for water drips at the cap or drain after shutdown. Smell of damp air in the intake tract suggests pooling. Rising pressure drop and a falling temperature differential indicate fouling from moisture and debris. Inspect for pits on tube ends, dark stains on the aluminum housing, and softened seals. Look for rust blooms near fasteners and the assembly base. Unusual hiss during load changes can reveal a leak created by corrosion. Frequent sensor faults may mask moisture-related failure modes, so confirm with physical checks.

Solutions to Prevent Condensation

Maintain steady coolant flow to keep heat exchangers stable during load changes. Add timed drain cycles after shutdown to purge condensate. Angle the cooler and routing to favor gravity drainage. Use epoxy-lined passages where saltwater aerosols or marine environment exposure reach the intake path. Select proper alloy pairs for tubes and seals to limit galvanic corrosion. Retorque fasteners on the aluminum housing to counter thermal expansion fatigue. Validate caps and vents. Mikura International can supply optimized components and kits that prevent moisture-related breakdowns.

Maintenance Tips for Locomotive Aftercoolers

Effective maintenance prevents condensation damage, corrosion, and mechanical failures in locomotive aftercoolers. The focus is early detection, correct cleaning, and timely replacement of worn parts. Short, disciplined tasks protect reliability and efficiency, avoiding costly downtime on rail schedules. Engineers and mechanics should monitor temperature, pressure drop, and drainage performance on every service. Use manufacturer specifications for torque and pressure testing. Keep records to pinpoint recurring failure modes. A proactive plan delivers longer life for the cooler assembly and safeguards the diesel engine.

Regular Inspection and Monitoring

Inspect the housing, tube bundle, seals, and caps weekly under normal service. Track temperature delta across the cooler at steady load to confirm proper cool performance. Record pressure drop to catch fouling before it escalates. Check for condensation on the air side after shutdowns and confirm free condensate flow. Examine each sealing surface and groove for pits, fatigue, and wear. Pressure test for leaks after any thermal event. Review trend data; sudden shifts suggest a defective component. Schedule targeted repairs before a breakdown occurs.

Best Practices for Cleaning Aftercoolers

Choose cleaners that protect copper, stainless, and aluminum without aggressive attack. Flush debris from tubes with controlled flow to avoid mechanical damage. Avoid high-pressure shocks that may open a latent leak. Dry the air side thoroughly to prevent residual moisture. Apply epoxy coatings only on approved surfaces to limit corrosion in harsh service. Reassemble with manufacturer-grade seals and verify torque on the aluminum housing fasteners. Calibrate sensors after cleaning to restore accurate diagnostics. Document results to refine intervals and reduce future risk.

When to Replace Aftercooler Components

Replace tubes or seals when pits exceed tolerance or fatigue marks appear near the groove. Any recurring leak, rising pressure drop, or unstable temperature differential signals end-of-life for the component. Swap caps and fasteners that lose clamp load after repeated expansion cycles. Retire an assembly with corrosion spreading across dissimilar alloy joints. If moisture carryover affects combustion quality or raises blow-by, prioritize replacement to protect the diesel engine. Mikura International provides validated parts for Cummins engines and other locomotive platforms to restore reliability and longevity.

Case Studies: Locomotive Aftercooler Failures in the Field

Operators often discover a failure only after a breakdown and costly downtime. The root issue is hidden condensation, corrosion, or a defective component inside the housing. Prevent engine failure by learning from field failures and applying proper maintenance. Use these insights to protect efficiency and longevity on rail service.

– Confirm drainage to stop condensate pooling in the cooler.

– Track temperature and pressure drop daily under load.

– Inspect the sealing surface and groove for pits.

– Retorque aluminum housing fasteners after heat cycles.

– Verify alloy compatibility across copper, stainless, and aluminum.

– Pressure test the assembly after any overload event.

– Use epoxy only on approved surfaces.

– Replace caps and seals when fatigue appears.

Real-World Examples of Aftercooler Failures

An operator reported rising pressure drop and a cool-side hiss under load. Inspection found pits at tube ends and a cracked seal near the groove. Condensation on the air side had attacked copper and stainless after repeated expansion cycles. Another case showed a leak at the cap on an aluminum housing, traced to torque loss and corrosion. A third event involved fouling from condensate mixed with saltwater aerosols, which degraded efficiency and produced moisture carryover into the diesel engine.

Lessons Learned from Aftercooler Issues

Every failure revealed a common chain: moisture, corrosion, and mechanical stress. Condensate left in the cooler increases risk of fatigue at each sealing surface. Poor torque control on the aluminum housing accelerates leaks during thermal expansion. Mismatched alloy pairs can drive galvanic attack. Incomplete cleaning forces recurring fouling and rising temperatures. Proper maintenance and timely replacement of seals prevent most failures. Operators who trend data avoid surprise defects and reduce costly downtime.

Improving Reliability Through Analysis

Start with technical baselines for temperature delta, pressure drop, and flow. Build control charts to flag step changes that suggest a leak or blockage. Correlate events to load cycles, coolant flow, and ambient conditions. Inspect tube ends, caps, and grooves after any heat spike. Use metallurgical review to assess alloy compatibility and corrosion rates. Validate condensate drainage paths with timed tests. Mikura International provides precision parts for Cummins engines and other locomotive platforms, helping engineers convert analysis into longer service life and reliability.

Conclusion: Enhancing Aftercooler Longevity

Longevity depends on dry air, stable temperatures, and strong sealing. Prevent condensation on the air side, control corrosion, and catch mechanical failures early. Verify torque on the aluminum housing, protect copper and stainless surfaces, and use compatible alloys. Track pressure drop and temperature to expose hidden failure modes. Replace defective components before they trigger engine failure. With disciplined maintenance, operators cut risk, protect combustion quality, and maintain rail schedules with fewer costly interruptions.

Summary of Key Points

Condensation drives corrosion and fatigue in the cooler assembly. Proper maintenance prevents leaks, pits, and seal defects. Monitor temperature delta and pressure drop to detect failures early. Use epoxy coatings only where manufacturer approvals exist. Confirm alloy pairing across copper, stainless, and aluminum surfaces. Retorque fasteners on the aluminum housing after thermal expansion events. Drain condensate, verify caps and vents, and pressure test after service. These steps improve efficiency, reliability, and longevity for locomotive diesel engines.

Final Tips for Locomotive Engine Owners

Keep drainage clear and schedule timed purge cycles. Inspect every sealing surface and groove during planned service. Replace caps, seals, and tubes at the first sign of fatigue or pits. Document all measurements for trend analysis. Avoid aggressive cleaning that risks a leak. Validate coolant flow to stabilize heat exchangers. Confirm material compatibility in marine environment exposure with saltwater aerosols. Use manufacturer-grade components to prevent defects. These actions prevent breakdowns, reduce downtime, and safeguard the diesel engine from costly failures.

Contacting Experts for Assistance

When data trends shift or defects persist, get expert support. Mikura International can audit your aftercooler, review condensate chemistry, and validate alloy choices. Our team advises on epoxy zones, torque specs for aluminum housing fasteners, and pressure testing methods. We stock precision tubes, caps, and seals for Cummins engines and related locomotive platforms. Engage us early to prevent a leak from becoming an engine failure. Fast parts supply and practical guidance restore reliability and service confidence on critical rail routes.