Converting Reciprocation to Locomotive Power

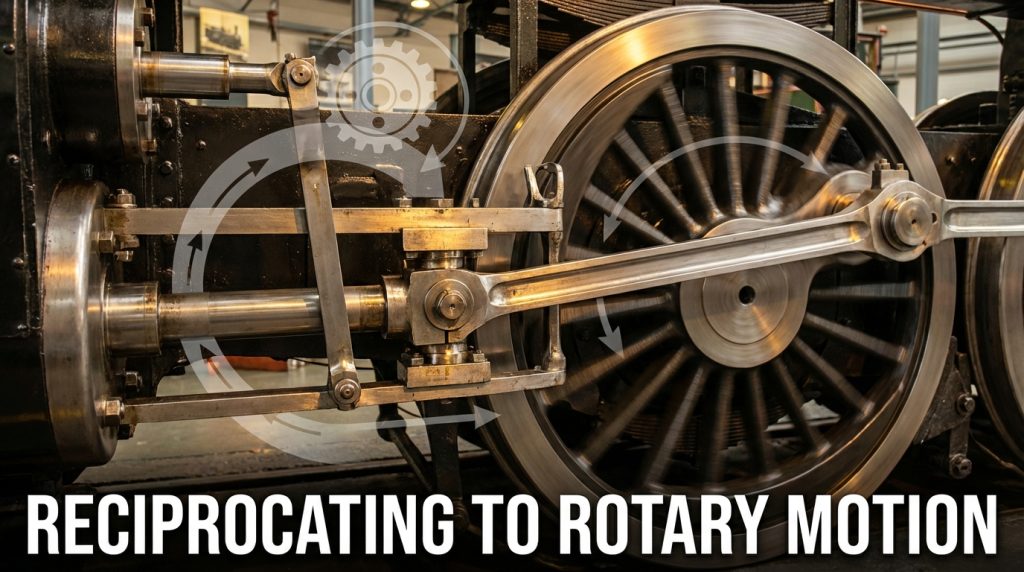

The core function of a Steam locomotive is the precise conversion of linear, high-force energy (derived from superheated steam expansion) into continuous rotational power for traction.

Spare parts sourcing managers frequently struggle with premature component wear, particularly in the critical motion components and piston valve assemblies. This issue directly diminishes operational efficiency and leads to unscheduled downtime.

Maintaining optimal performance requires absolute precision in component specification. The complex interplay between high-pressure fluid dynamics and the mechanical linkage responsible for controlling steam admission demands rigorous maintenance protocols.

To mitigate these critical pain points, minimize operational downtime, and maximize the lifespan of your heavy-duty components, implement the following rigorous operational controls:

- Implement non-destructive testing (NDT) on connecting rods quarterly to detect micro-fractures before catastrophic failure.

- Verify alignment tolerances for piston heads and cylinder bores during every major overhaul cycle to prevent uneven load distribution.

- Ensure specialized lubrication procedures are strictly followed for the crosshead assembly and valve spindle components.

- Source all replacement components, especially Piston valve rings and bushings, manufactured strictly to certified original equipment specifications.

- Monitor steam chest pressure fluctuations closely to diagnose potential leakage or wear in the Piston valve assembly, ensuring proper steam admission.

- Train maintenance teams on the precise setting and inspection of the valve gear timing, minimizing wasted steam and maximizing steam efficiency.

- Regularly inspect the crank pin and main bearing surfaces for signs of uneven load distribution, a critical indicator of underlying linkage misalignment.

Expert Insight

“Operational longevity in complex machinery relies on a proactive strategy: combining advanced diagnostics, like vibration analysis and NDT, with unwavering adherence to component alignment and specialized lubrication protocols.”

I. The Mechanical Chain: From Piston Thrust to Rotational Output

The conversion of linear force generated by high-pressure steam into usable rotational power is executed through a precise, four-part mechanical linkage. This fundamental process defines the power output characteristics of the Steam locomotive.

Sourcing reliable components for this linkage is essential. These parts must manage immense cyclical forces to prevent premature wear and catastrophic failure, a common pain point for sourcing managers.

Initiating Reciprocation via Controlled Steam Admission

The cycle begins when Superheated steam is admitted into the Locomotive cylinder. This admission is precisely managed by the Piston valve (or, in older designs, the Slide valve) operating within the Steam chest.

High-intensity pressure forces the Piston heads to move linearly, or reciprocate, within the bore. Controlled Steam admission and exhausting ensures continuous power delivery throughout the stroke, maintaining high operational efficiency in the Steam engine.

Critical Components in the Conversion Sequence

The system relies on a sequence of robust components designed to translate this linear force while absorbing significant transverse and axial stresses. Understanding the function and stress profile of each element is critical for optimal component specification:

- The Piston Rod: This component transmits the axial force generated by the piston heads through the cylinder cover stuffing box. Its primary function is pure force transfer, demanding high tensile strength and precise alignment retention.

- The Crosshead Assembly: The crosshead acts as a crucial guide, ensuring the piston rod travels in a perfectly straight line. It absorbs the intense angular thrust generated by the main Connecting Rod, preventing destructive bending forces on the piston rod. Proper maintenance of the crosshead slides minimizes friction and lateral wear.The Connecting Rod (Main Rod): This rod attaches the crosshead to the crank pin on the driving wheel. This component executes the actual conversion. As the piston pushes the connecting rod linearly, the constraint imposed by the crank pin forces the crank to rotate, transforming the back-and-forth movement into continuous circular motion. 10 Best Ways Locomotive Pressure Drives Movement.

- The Crank Pin and Driving Wheel: The crank pin is offset from the center of the wheel axle, defining the stroke length. The leverage applied by the connecting rod to this offset point creates the high torque necessary to propel the Steam locomotive.

Expert Insight: Managing Angular Thrust

The most significant stress point in this system, related to sourcing replacement parts, is the interface between the connecting rod and the crosshead. This joint handles the transition from purely linear force to rotational torque, generating substantial side loads.

Sourcing high-grade crosshead assemblies and specialized guide materials is paramount to mitigating frictional resistance and ensuring the durability required for heavy-duty service.

Expert Insight

“The power of a steam locomotive hinges on running gear precision; ensuring the engine is in tram and maintained to proper tolerances is key to efficiently managing the substantial angular thrust generated at the critical crosshead-to-connecting rod interface.”

II. Controlling Power: The Function of the Piston Valve and Steam Efficiency

Sourcing managers must assess whether the original design utilized simpler systems like locomotive valve gear or more complex linkages like Walschaerts valve gear or Baker valve gear, as the required Valve spindle and linkage components differ significantly across these configurations.

III. Precision Control via Locomotive Valve Gear Systems

Sourcing reliable components for the valve gear linkage is paramount, as wear here directly translates to poor Steam efficiency and inconsistent power delivery. The primary function of the Valve gear is to precisely regulate the motion of the Piston valve or Slide valve, determining the timing and duration of Steam admission and Exhaust steam release within the Locomotive cylinder.

The motion of the Piston valve is governed by these complex mechanical linkages. The design of the Valve gear dictates the timing, duration, and cut-off point of Steam admission, directly impacting the engine’s power, speed, and overall operational stability.

Foundational Engineering and Valve Timing Analysis

The foundational understanding of efficient steam utilization originated with engineers like Franz Reuleaux and Gustav Zeuner. Their graphical analysis methods, particularly the Cylinder diagram, remain vital for optimizing valve events and ensuring maximum power extraction from Superheated steam.

The robust operation required for heavy-duty Steam locomotive service led to the widespread adoption of standardized, reliable systems. The Stephenson valve gear and the Walschaerts valve gear represent the most common mechanisms for controlling the Valve spindle.

Analyzing the Walschaerts Valve Gear Mechanism

The Walschaerts valve gear is an external mechanism preferred for its accessibility, simplifying maintenance and inspection routines. This system controls the Piston valve movement by combining inputs from two distinct sources, ensuring synchronization with the main Piston heads.

The two primary motion sources are:

- Eccentric Crank: Provides the primary reversing and travel motion, governing the position of the combination lever.

- Crosshead Link: Derives motion from the main crosshead, compensating for the angularity of the connecting rod and providing the necessary Lead (valve timing).

The precise setting of Steam lap and Exhaust lap within the Piston valve design, combined with the engineer’s ability to adjust the cut-off, dictates how long Steam admission occurs. This precision control is essential for maximizing Steam efficiency across varying speeds, minimizing operational cost.

Advanced Optimization for High-Speed Steam Flow

Pioneering work by engineers such as André Chapelon focused heavily on mitigating pressure drop during high-speed operation. Chapelon emphasized using large-diameter Piston valve designs and optimizing Walschaerts valve gear geometry to reduce wire-drawing and throttling of the Superheated steam.

Proper Valve lubrication is critical for the longevity of the Valve spindle and its bushings within the Steam chest. Inadequate lubrication leads to scoring and increased friction, directly diminishing the precision of the valve events.

The choice between Inside admission (where steam enters the valve chest between the piston heads) or Outside admission affects the thermal environment of the engine. Inside admission is often favored with Superheated steam as it keeps the hottest steam away from the valve spindle packing glands, improving component life and reducing maintenance frequency.

Specialized Valve Systems for Enhanced Volumetric Efficiency

While the Piston valve remains dominant, specialized systems were developed for superior volumetric efficiency. The Poppet valve utilizes cam-actuated lift valves instead of the sliding motion required by the Slide valve or Piston valve.

Systems like the Caprotti valve gear employ independent cams for inlet and exhaust, allowing precise, separate timing adjustments for Steam admission control and Steam exhausting. This level of control significantly enhanced Steam efficiency in high-performance engines, notably achieving success in designs like the SR Merchant Navy class.

Alternative linkages, such as the Baker valve gear, offered simplified maintenance and reduced the number of pins and joints compared to earlier internal linkages like the Stephenson valve gear, while still providing the precise control needed for efficient use of Superheated steam.

The fundamental principle for maximizing power output in a reciprocating Steam engine is ensuring rapid, unrestricted Steam admission and exhaust. Failures in the Valve gear linkage or wear on the Piston valve can severely restrict flow, rendering the Steam locomotive inefficient and unreliable. Sourcing managers must prioritize quality components for these high-stress linkages.

Expert Insight

“The inherent function of the valve gear is to manage the critical balance between maximum power output, requiring long steam admission for starting, and operational efficiency, which is achieved through precise, adjustable cut-off timing to minimize steam waste.”

IV. Maintenance Protocol for Sourcing Managers: Ensuring Component Longevity

Sourcing managers must prioritize component integrity in the motion work to guarantee maximum uptime for the heavy-duty Steam locomotive fleet. Premature failure of critical reciprocating parts directly impacts the overall Steam efficiency and requires immediate, costly intervention.

1. Crosshead and Connecting Rod Procurement Specifications

The main connecting rod transmits colossal forces and operates under cyclical stress reversal during the conversion of linear motion to rotational power. Specifying and procuring high-quality replacements is non-negotiable to prevent catastrophic failure in the Steam engine.

- Bearing Material Certification: Demand certification proving the bearing surfaces at the crank pin and crosshead pin utilize specified high-load alloys (e.g., specialized bronze or babbitt). Concentricity must be verified upon delivery.

- Fatigue Crack Inspection: Ensure replacement rod strap bolts and connecting rod assemblies have undergone Non-Destructive Testing (NDT), such as Magnetic Particle Inspection (MPI). Use only certified high-tensile steel replacements designed for high-stress applications in the Locomotive cylinder environment.

- Guide Alignment Tolerances: Verify that replacement crosshead shoes meet the strict tolerances required for the crosshead guides. This minimizes friction and prevents misalignment that stresses the piston heads and main rod assembly.

2. Piston Valve and Steam Chest Integrity for Optimal Steam Flow

Maintaining the components that control steam flow is vital for achieving the high performance standards exemplified by designs studied by engineers like André Chapelon. The transition from the older Slide valve to the modern Piston valve demanded better sealing against the pressures of Superheated steam.

The high temperatures associated with Superheated steam necessitate exceptional material quality in both the Piston valve and the surrounding Steam chest liner.

Critical Checks for Piston Valve and Steam Chest Components

- Piston Valve Ring Sealing Assessment: Regularly assess the sealing rings on the Piston valve for wear. Worn rings cause steam blow-by, which significantly reduces pressure applied to the Piston heads and degrades overall Steam efficiency. While some contemporary engines utilize the Poppet valve, the majority of heavy Steam locomotive fleets rely on robust Piston valve systems.

- Valve Spindle Straightness: The integrity of the Valve spindle must be verified. Any deflection will cause uneven ring wear and potential binding within the Steam chest liner, disrupting precise Steam admission and Exhaust steam cycles.

- Gland Packing Maintenance: Specify high-grade packing materials for the glands around the valve and piston rods. Effective packing prevents steam leakage, conserving energy and maintaining the integrity of the critical Valve lubrication system.

Sustaining the heavy freight service demands placed on powerful engines, such as the Pennsylvania Railroad class I1s, requires continuous vigilance over these specialized components. By sourcing quality replacement parts designed specifically for high-stress applications, you ensure the specified component life cycles of the Steam engine are met.

Focusing on components that ensure accurate Steam admission and efficient exhausting is the primary strategy for maximizing locomotive performance.

V. Frequently Asked Questions

What mechanical factors cause premature wear in the main motion components?

Premature failure of components like the crosshead, connecting rod, and piston heads often stems from misalignment during installation or the use of incorrectly specified materials that cannot handle the cyclic stress loads.

Sourcing managers must verify that replacement components meet precise metallurgical standards to resist fatigue failure, especially where the connecting rod interfaces with the crank axle.

Inadequate lubrication, particularly in the harsh operating environment of a heavy-duty Steam locomotive, is a leading factor. Ensure all components are compatible with required high-pressure lubricants for the specific application.

How critical is the Piston valve design to overall Steam efficiency?

The Piston valve is fundamental to achieving high Steam efficiency in modern Steam engine designs compared to the older Slide valve technology.

Piston valves are necessary to manage the high temperatures and pressures associated with Superheated steam, which significantly improves engine performance.

They provide superior sealing within the Steam chest, allowing precise Steam admission control and minimizing leakage of the working fluid, which directly impacts the locomotive’s power output.

What role does specialized Valve gear play in optimizing locomotive performance?

The Valve gear system, such as the Walschaerts valve gear or the Stephenson valve gear, dictates the precise timing of steam entry and exit from the Locomotive cylinder.

Optimized valve timing is achieved by adjusting parameters like steam lap and lead, ensuring that the Control steam flow maximizes expansive work while minimizing back pressure during Exhaust steam release.

Engineers like André Chapelon rigorously advanced the design of valve gear and steam pathways, demonstrating that precise timing is essential for maximizing the thermal and mechanical efficiency of the Steam locomotive.

What specifications should be prioritized when sourcing components for high-pressure Steam chests?

When sourcing parts related to the Steam chest, prioritize material strength and resistance to thermal shock. The constant cycling of high-pressure, Superheated steam demands specialized alloys.

Focus on maintaining extremely tight tolerances for the Valve spindle and the Piston valve itself to ensure effective sealing and prevent costly leakage, which degrades overall Steam efficiency.

Always confirm that the components are manufactured to handle the specific operational parameters set by the original design, such as those used in the Pennsylvania Railroad class I1s or SR Merchant Navy class engines.

What is the primary difference between a Slide Valve and a Piston Valve?

The fundamental distinction lies in sealing and operational balance. The Slide valve utilizes flat surface contact. This design generates significant friction, particularly when handling high pressures or superheated steam, making adequate valve lubrication challenging.

In contrast, the Piston valve is cylindrical and operates within a steam chest. Steam pressure acts equally around its circumference, achieving hydraulic balance. This drastically minimizes friction and is essential for high-temperature applications, often employing configurations like inside admission or outside admission. This superiority led to its adoption in most modern steam locomotive designs.

How does Valve Gear affect Steam Efficiency?

Valve gear controls the precise timing of steam admission and the release of exhaust steam. Efficiency is directly proportional to how long the steam is allowed to work expansively within the locomotive cylinder.

Systems like the Walschaerts valve gear or the rotary Caprotti valve gear enable the engineer to accurately adjust the cut-off point. Reducing the cut-off means steam is admitted for only a small fraction of the stroke, allowing maximum expansion.

This maximization of expansive work significantly increases steam efficiency. Advanced designs, often inspired by engineers like André Chapelon, rely on optimized valve gear settings to dramatically improve power output and fuel economy for the steam engine.

Why is the Crosshead assembly so critical for rod conversion?

The crosshead assembly is indispensable because it acts as a mechanical interface, successfully isolating the purely linear motion of the piston rod from the angular thrust generated by the connecting rod.

This isolation is crucial. If the angular forces required to turn the crank pin were transmitted directly to the piston, severe bending moments would be imposed on the rod and the piston heads.

Such stress would rapidly accelerate wear on the locomotive cylinder walls and inevitably lead to catastrophic component failure. The crosshead ensures the piston reciprocates with precise linearity, protecting the entire power assembly.

You may be interested in reading: Piston valve (steam engine) – Wikipedia