You’ll replace EMD locomotive pinion gears when wear progression threatens your entire drivetrain system. Critical replacement triggers include feeler gauge measurements reaching 0.24mm thresholds, surface pitting on both sides of pitch points, and scuffing from lubrication film breakdown. Worn pinions cause misalignment-induced tooth fractures, bearing heat damage, and immediate locomotive immobilization. Emergency replacements cost 200-400% more than scheduled maintenance, while preventive replacement using remanufactured components saves 30-40%. Proper monitoring protocols and measurement techniques guarantee optimal replacement timing for maximum operational efficiency.

Key Takeaways

- Misalignment issues and axial run-out create uneven tooth contact patterns leading to premature wear and deterioration.

- Surface pitting on both sides of pitch point indicates tribological breakdown requiring immediate gear replacement.

- Lubrication film breakdown causes scuffing and metal-to-metal contact, generating excessive heat beyond safe operating limits.

- Manufacturing defects like insufficient case depth and heat treatment anomalies compromise gear integrity and service life.

- Tooth fracture from concentrated loading and reverse fatigue creates critical failure modes necessitating urgent replacement.

Primary Causes of Pinion Gear Deterioration in EMD Locomotives

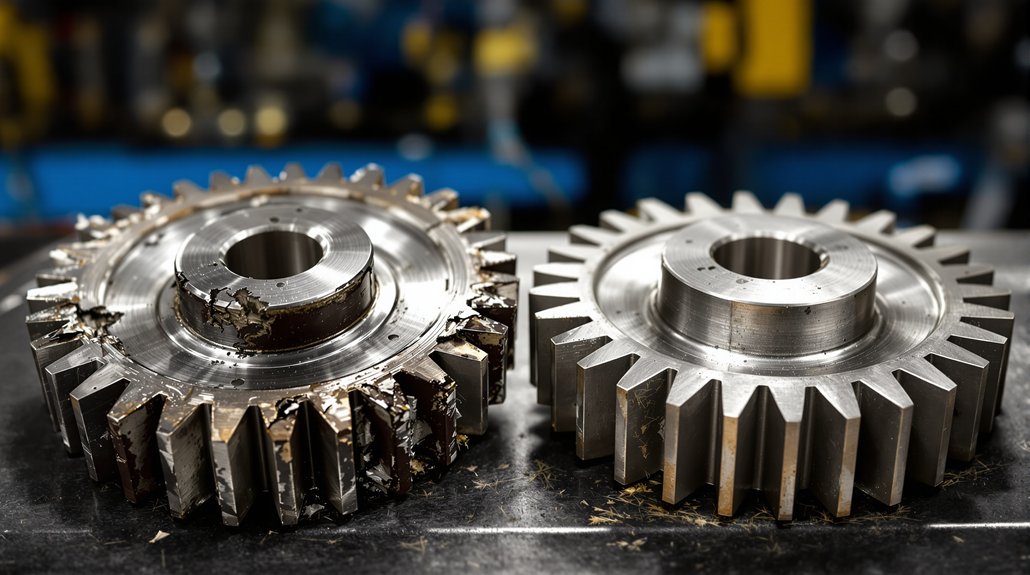

When examining EMD locomotive pinion gear failures, you’ll find that misalignment issues consistently rank as the primary cause of premature deterioration. Axial run-out creates uneven tooth contact patterns, while axial eccentricity between bearing bore and outer diameter produces irregular loading cycles that accelerate wear progression.

Surface contact damage compounds these problems through inevitable sliding at dedendum, pitch point, and addendum sections. You’ll observe pitting development on both sides of the pitch point as tribological factors intensify material loss during operation.

Lubrication degradation markedly accelerates deterioration rates. When lubricant film breaks down between tooth surfaces, you’re dealing with scuffing damage and increased friction coefficients. Contaminated lubrication systems create abrasive wear patterns that reduce component lifespan. Additionally, debris contamination in the gear housing introduces foreign particles that create scoring damage on tooth surfaces.

Excessive load conditions worsen these issues when only portions of designed gear face width carry operational loads, creating concentrated stress points that lead to premature fractures and discoloration patterns.

Critical Failure Modes That Demand Immediate Pinion Replacement

Several critical failure modes in EMD locomotive pinion gears require immediate replacement to prevent catastrophic drivetrain damage and costly operational downtime. You’ll encounter reverse fatigue when multiple initiation sites develop at opposing mid-tooth locations, creating fracture surfaces that compromise structural integrity. This failure pattern typically presents with a third initiation site at the tooth end, demanding urgent attention.

Surface pitting at both sides of the pitch point indicates tribological breakdown requiring immediate intervention. When you observe misalignment-induced tooth fracture from angular meshing conditions, replacement becomes critical as load concentration exceeds design specifications on active gear face portions.

Scuffing from complete lubrication film breakdown represents another immediate replacement trigger. You’ll need tooth realignment procedures during replacement to address axial run-out and eccentricity issues. Thermal distress causing case hardness loss, combined with bearing temperatures exceeding atmosphere plus 120°C, signals urgent replacement requirements to maintain locomotive operational safety and performance standards.

Manufacturing Defects That Compromise EMD Pinion Performance

Manufacturing defects in EMD pinion gears create systemic vulnerabilities that’ll compromise locomotive performance long before normal wear patterns emerge. Heat treatment anomalies represent the most critical failure pathway—incorrect carburizing operations produce insufficient case depth below 0.2mm specifications, while quench furnace temperature variations create inconsistent hardness distribution throughout your pinion body.

Material segregation during forging concentrates impurities at stress points, accelerating fatigue crack initiation. You’ll encounter profile deviations exceeding tolerance limits when manufacturers use improper tooth cutting procedures, creating meshing irregularities that generate destructive vibrations.

Case hardening defects leave soft surface areas vulnerable to accelerated wear, while contaminated gear compounds degrade lubrication effectiveness. Bore diameter inconsistencies prevent proper motor shaft fitment, causing misalignment-induced failures. Proper gear alignment during installation becomes critical to compensate for manufacturing tolerances and prevent premature failure modes.

Quality control breakdowns compound these issues—inadequate inspection procedures allow defective pinions into service, while incorrect backlash measurements at TM ends rather than wheel ends provide false assembly parameters.

Measuring Wear Limits and Establishing Replacement Criteria

You’ll need precise measurement techniques to determine when your EMD pinion gears have reached condemning limits and require replacement. The involute profile gauge method using feeler gauges provides the most accurate assessment, with the industry-standard 0.24mm gap serving as your critical replacement benchmark. Your feeler gauge inspection protocol must target specific measurement points on the gear tooth flanks to quantify wear deviation from the original involute profile. Alternative inspection methods include using soft lead wire positioned at the minimum point between meshing teeth to measure backlash, though the wire thickness must exceed the expected backlash by up to three times for accurate readings.

Involute Profile Gauge Methods

When measuring involute wear on EMD locomotive pinion gears, you’ll rely on profile deviation measuring gauges that utilize p-value and k-value measurements with feeler gauges for standard bull gear 65 teeth mating pinion 16 teeth configurations. These specialized gauges enable precise involute mapping and contact analysis to determine deviation from original tooth profiles.

Your measurement process involves three critical steps:

- Gauge positioning – Place the profile gauge against one side of the tooth profile to create measurable gaps

- Gap quantification – Insert feeler gauges through openings to measure involute wear starting at 0.24mm thresholds

- Profile comparison – Compare actual measurements against original design specifications to identify wear progression

You’ll find these gauges mirror the original tooth profile design, establishing baseline measurements for accurate variance detection between worn and specified configurations.

0.24mm Gap Benchmark Standards

After mapping involute wear through profile gauge measurements, you’ll establish replacement criteria using the 0.24mm gap benchmark standard. This condemning specification determines when gears and pinions require removal from service based on tooth profile clearances measured through feeler gauge insertion.

| Assessment Parameter | Specification |

|---|---|

| Maximum Gap Tolerance | 0.24mm |

| Measurement Method | Feeler Gauge |

| Application Scope | New & Re-profiled |

| Service Action | Condemning Limit |

| Evaluation Type | Tooth Thickness |

Your metric calibration procedures must verify gauge accuracy before conducting gap measurements. Both new component assessment and re-profiled gear evaluation follow identical tolerance requirements. Material traceability documentation guarantees compliance with ASTM 837 standards throughout the replacement decision process. When gaps reach or exceed this threshold, you’ll initiate component replacement protocols rather than attempting further re-profiling procedures. Comprehensive vibration monitoring systems track gear mesh frequencies to detect early signs of deterioration before reaching condemning limits.

Feeler Gauge Inspection Protocols

Carrying out feeler gauge inspections requires systematic measurement protocols that build upon the 0.24mm gap benchmark you’ve established. These clearance checks demand precise blade calibration to guarantee accurate wear assessments across all pinion gear contact surfaces.

Your inspection protocol must include:

- Calibrated blade selection – Use manufacturer-certified feeler gauges with verified thickness measurements for consistent clearance checks

- Multiple measurement points – Document gap measurements at minimum three locations around each gear tooth interface

- Torque specification verification – Cross-reference clearance readings with EMD technical specifications before determining replacement necessity

You’ll need to document each measurement systematically, comparing readings against established wear thresholds. When clearance measurements exceed manufacturer limits or show inconsistent patterns, you’ve identified components requiring immediate replacement to prevent cascading traction system failures and maintain locomotive operational reliability. Safety inspections must include exposed gears within the engine compartment to identify defects that could compromise operational integrity.

Secondary System Failures Triggered by Worn Pinion Gears

When you ignore worn pinion gear replacement schedules, you’ll encounter support bearing heat damage as misalignment forces excessive loads through the bearing assembly. The resulting thermal stress breaks down bearing lubricant properties and creates metal-to-metal contact that generates destructive heat cycles. You’ll then face oil leakage cascade effects as deteriorated seals and gaskets fail under increased operating temperatures, contaminating adjacent systems with debris-laden lubricant. Field technicians often mistake these secondary failures for slipped pinion conditions when the actual problem involves electrical system malfunctions that simulate locked axle symptoms.

Support Bearing Heat Damage

Worn pinion gears consistently trigger a destructive cascade of secondary failures that devastates support bearing systems through excessive heat generation. When gear misalignment creates metal-to-metal contact, frictional heat exceeds safe working limits of atmosphere temperature plus 120°C maximum. This thermal stress causes silver-and-lead bearing material to soften and extrude into oil channels, blocking lubricant flow.

Critical Heat Damage Indicators:

- Thermal mapping reveals exact locations where bearing temperatures exceed operational thresholds

- Lubricant chemistry breakdown accelerates when film strength fails under marginal lubrication conditions

- Steel-to-steel contact occurs after protective bearing material completely wears away from heat exposure

You’ll observe progressive wear patterns starting with surface material displacement, followed by wristpin burning and heavy scoring as bearing protection fails completely.

Oil Leakage Cascade Effects

Heat-damaged support bearings create the initial failure point that triggers a destructive oil leakage cascade throughout the entire pinion gear system. You’ll observe that worn bearings generate excessive pinion movement, damaging sealing surfaces and creating primary oil seepage points. This leaked oil attracts environmental contaminants, establishing contamination pathways that accelerate system-wide degradation.

Your gear case experiences secondary seal failures as misalignment stresses propagate through the sealing system. Grooved pinion flanges develop from continuous wear, allowing persistent oil seepage even after seal replacement. Drive shaft damage from dents or cracks generates vibration that accelerates seal wear and compounds the leakage problem. You’ll face escalating repair costs as contaminated oil circulation damages precision-machined surfaces throughout the gear train. The cascade effect transforms isolated bearing wear into all-encompassing system failure, requiring complete component replacement rather than targeted maintenance interventions.

Operational Disruptions Caused by Failed EMD Pinions

Once EMD locomotive pinion gears fail, you’ll face immediate and severe operational disruptions that can bring your entire rail operation to a standstill. Failed pinions create three critical operational challenges:

EMD pinion gear failures trigger immediate locomotive immobilization and cascading operational disruptions that can paralyze entire rail networks.

- Immediate locomotive immobilization – Your units become essentially immovable when wheel pairs lock up, requiring emergency repairs wherever they stop, including on main tracks

- Cascading service delays – You’ll experience significant revenue loss as disabled locomotives block critical rail infrastructure until repairs are completed

- Emergency repair complications – Your crews must perform repairs in challenging field conditions, creating crew safety hazards and requiring specialized equipment access

You’ll need to nurse disabled units into sidings when possible to minimize main line disruption. Slipped pinions rank among the three primary causes of locomotive immobilization alongside seized motor armatures and failed journal bearings. Torsional vibration from damaged pinion teeth affects operational stability, while progressive gear wear leads to increasingly severe disruptions over time.

Cost Analysis of Preventive Versus Emergency Pinion Replacement

The financial impact of EMD pinion gear failures extends far beyond the immediate operational disruptions, creating a compelling case for preventive replacement strategies. Emergency replacements force you into expedited procurement scenarios where pinion gear costs increase 200-400% over standard pricing. You’ll face overnight shipping charges and premium labor rates at 150-200% of normal maintenance costs.

Preventive replacement enables inventory optimization through bulk purchasing and scheduled maintenance windows. You can utilize remanufactured components at 60-70% of new part costs while avoiding overtime premiums. Emergency repairs often require specialized technician callouts and extended diagnostic procedures to assess secondary damage to bull gear assemblies.

Your preventive approach minimizes revenue-generating downtime by scheduling replacements during planned maintenance windows. Emergency failures create missed freight schedules, potential contract penalties, and customer dissatisfaction. Proper preventive measurement using profile deviation gauges prevents cascade failures that compound repair costs exponentially. Quality suppliers with North American manufacturing capabilities ensure faster delivery times and reduced supply chain risks during planned maintenance cycles.

Best Practices for EMD Pinion Gear Maintenance and Replacement Scheduling

While emergency repairs drain resources through reactive responses, implementing systematic maintenance protocols transforms pinion gear management into a predictable cost center with measurable performance outcomes.

Systematic maintenance protocols transform reactive pinion gear repairs into predictable cost centers with measurable performance outcomes.

You’ll maximize component lifespan through three critical maintenance practices:

- Scheduled Inspections Every 92 Days – Assess pinion gears for pitting, scoring, and uneven wear patterns. Check axles for discoloration indicating excessive stress. Compare findings against your locomotive’s minimum continuous speed and tonnage ratings.

- Lubricant Audits Using GE-Approved Specifications – Apply high-grade lubricants designed for high-load gear systems. Clean traction motor pinions regularly to remove abrasive grime that accelerates wear.

- Torque Verification with Calibrated Equipment – Follow manufacturer’s specifications meticulously during installation. Re-check torque after initial operation periods to confirm proper tightening.

You’ll prevent cascading failures by addressing wear issues promptly. Monitor consistent wear patterns as performance indicators, integrating proactive practices that minimize downtime while extending your pinion gear service intervals. The pinion’s high-speed carbon steel construction provides superior durability under demanding operational conditions.

Frequently Asked Questions

Can Worn EMD Pinion Gears Be Refurbished Instead of Replaced?

Ironically, you’ll often spend more replacing what could’ve been saved. Yes, you can refurbish worn EMD pinion gears when wear measurements remain within acceptable limits. Your refurbishment process requires systematic visual inspection, precise tolerance verification, and specialized heat treatment including case hardening and carburizing operations. Critical factors include maintaining 0.13mm axle bore alignment, using refurbished bearings, and ensuring spline dimensions meet manufacturer specifications before determining refurbishment feasibility.

What Is the Typical Lifespan of EMD Pinion Gears Under Normal Operation?

You’ll typically see EMD pinion gears lasting 500,000 to 1,500,000 miles under normal operating conditions, depending on your locomotive’s service intervals and load cycles. Heavy freight operations with high tractive effort demands reduce lifespan to the lower range, while passenger service extends it. You should expect 8-15 years of service life with proper lubrication maintenance and adherence to manufacturer-specified torque settings during installation.

Are Aftermarket Pinion Gears Compatible With Original EMD Locomotive Specifications?

You’ll find aftermarket compatibility with original EMD specifications when suppliers maintain identical diametral pitch requirements of 2.25 and 20-degree pressure angles. Leading manufacturers like SUPCO Canada and PowerRail guarantee their material standards match EMD’s carburizing processes and hardening cycles. Cross-reference systems let you identify compatible parts using original EMD numbers like 9556211 or 8452310, maintaining proper gear mesh and operational reliability.

How Do Weather Conditions Affect EMD Pinion Gear Replacement Frequency?

While pinion gears endure constant mechanical stress, you’ll find temperature extremes create the harshest replacement conditions. You’re dealing with accelerated wear when operating in sub-zero conditions versus desert heat – thermal expansion cycles stress gear teeth differently. Moisture intrusion becomes your primary concern in humid environments, causing corrosion that compromises gear integrity. You’ll need more frequent inspections and replacements in coastal or high-humidity regions where salt accelerates deterioration.

What Special Tools Are Required for EMD Pinion Gear Removal and Installation?

You’ll need specialized hydraulic removal tools rated for 40,000 PSI, dual air-powered pump systems, and hydraulic pinion puller sets with tube-to-motor shaft adapters. Essential precision instruments include dial indicators for alignment verification, pinion taper plug gauges for D90 motors, and armature shaft taper gauges. You’ll also require calibrated torque wrenches, EMD-specific pinion nut wrenches, and various adapters including MAC 90 pinion adapters with 3/4″ hex configurations.