Target wasted braking heat and convert it to usable power with regenerative braking. Many electric locomotives already support regenerative braking, yet settings, maintenance, and network constraints often limit results. Address battery readiness, grid receptivity, and dynamic control tuning. The benefit compounds over asset life and lowers cost. Mikura International supports operators with expert parts and guidance to match demand, reduce consumption, and optimize generation across complex routes.

Audit the use of dynamic and regenerative braking across different grades and speeds. To structure this assessment clearly, focus on the following:

- Evaluate braking performance on varying track grades.

- Review braking behavior at different speed ranges.

- Check inverter firmware for regenerative braking efficiency maps.

- Verify grid or wayside battery capacity to absorb returned power.

- Calibrate brake blending between friction and dynamic modes.

- Monitor wheel-rail adhesion to prevent regen cut-out.

- Add onboard battery to capture excess generation off-peak.

- Align driver training with energy targets and traction limits.

- Use data logs to track consumption, recovered power, and cost.

- Maintain traction motors and cooling to protect component life.

- Coordinate with network operators for receptivity windows.

Understanding Regenerative Braking in Locomotives

Regenerative braking converts a locomotive’s kinetic energy into electrical power during deceleration. Instead of wasting energy as heat in a brake resistor, the traction motors act as generators. The recovered energy can feed a receptive grid, a wayside network, or an onboard battery to reduce consumption and cost. When trains use regen well, component life improves because friction brake duty drops. The larger the demand for electricity nearby, the greater the benefit.

What is Regenerative Braking?

Regenerative braking is a dynamic train braking method that turns motion into electrical power. In electric locomotives, traction motors switch from motoring to generation. Energy flows back to the grid or into a battery when the network is receptive. This lowers fuel or electricity consumption and reduces brake wear. The system supplements, rather than replaces, friction brakes for safety. Operators gain a life cycle benefit through lower heat stress and reduced cost per kilometer.

How Does Regenerative Braking Work?

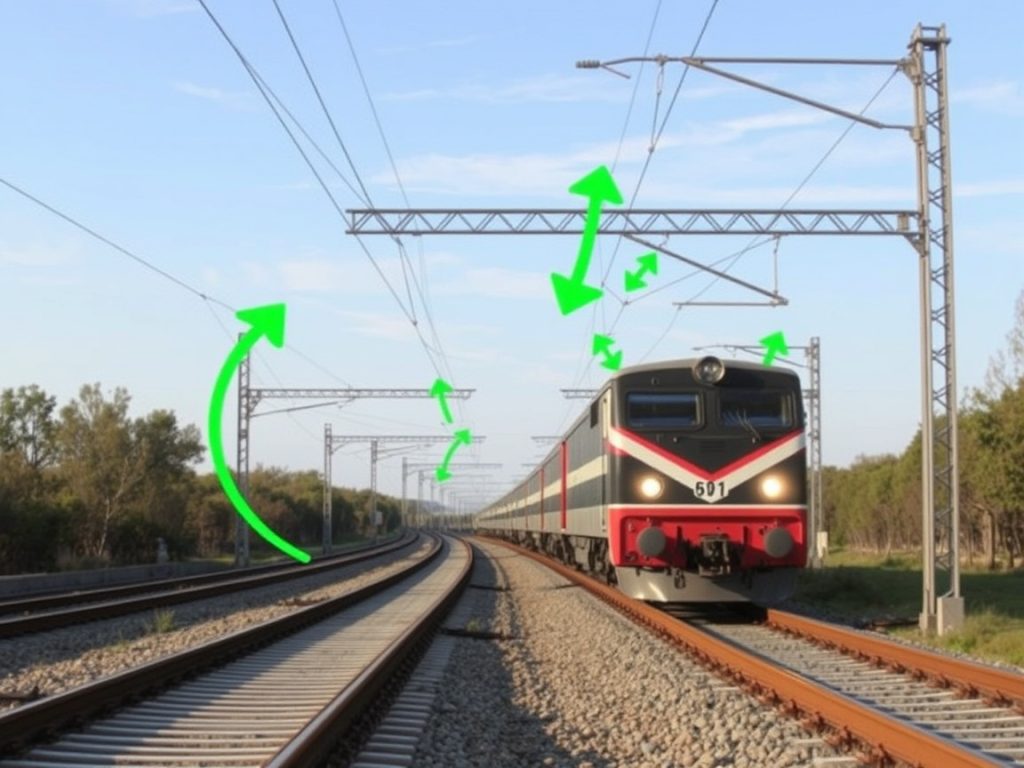

During deceleration, control systems command the traction motors to generate. The inverter regulates voltage and current to match grid or battery demand, while brake blending meets the target rate. If the catenary or third-rail can accept power, energy flows upstream; if not, an onboard battery captures the surplus generation. Adhesion control prevents wheel slip so trains use maximum regen safely. Proper tuning lowers consumption and stabilizes train handling.

Benefits of Regenerative Braking

Lower energy consumption, reduced brake wear, and improved component life. Networks gain when multiple trains use regen, sharing power locally. Onboard battery systems store excess generation when grid demand is low. The result is smoother train braking, better thermal margins, and higher availability. With expert parts from Mikura International, upgrades integrate cleanly and reliably.

Components of a Regenerative Braking System in Locomotives

High efficiency depends on coordinated control, safe brake blending, and a receptive grid or battery. When demand varies across a network, systems must buffer and route energy. Proper sizing and tuning lower consumption and cost while protecting component life. The following sections explain each key brake element, integration with existing systems, and the maintenance practices that preserve benefit across fleets.

Key Components Explained

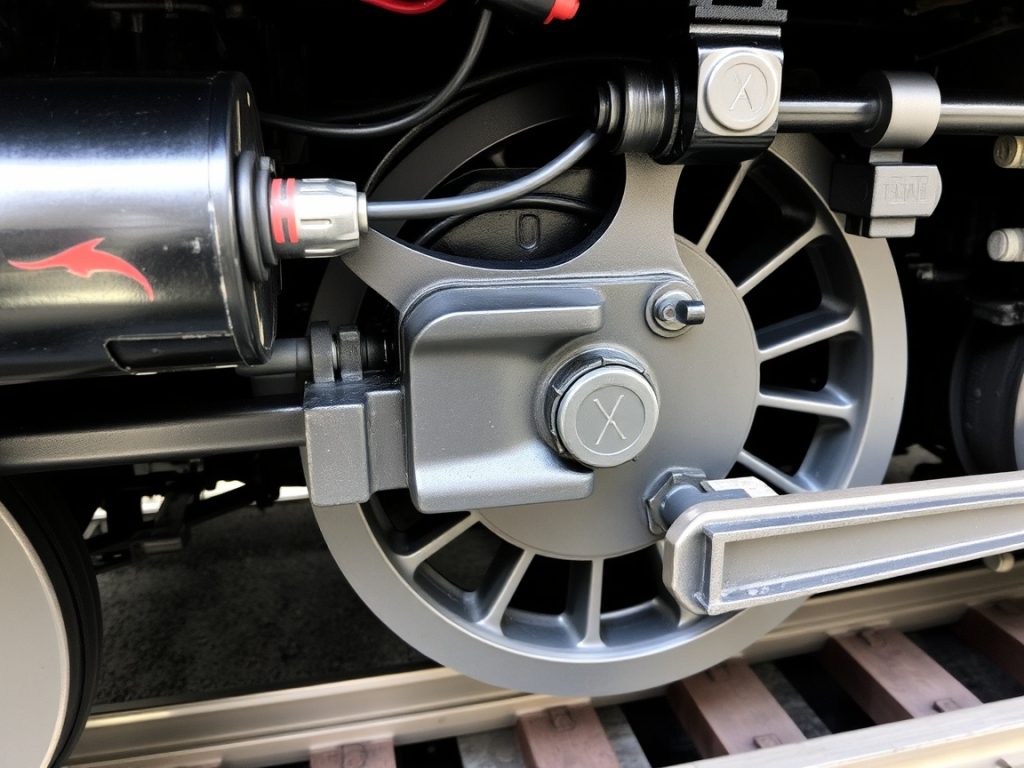

Traction motors act as generators during regenerative braking and convert motion to electrical power. The traction inverter manages voltage, current, and frequency to match grid receptivity or battery charge limits. A DC link and filter stages stabilize dynamic energy flow and protect equipment. Brake control units handle blending to meet target deceleration and keep train braking smooth. Adhesion management keeps wheels stable under changing demand. Wayside or onboard batteries store surplus generation when the network cannot absorb it. High-reliability contactors, sensors, and cooling close the loop.

Integration with Existing Brake Systems

Brake blending prioritizes regenerative braking to lower heat and cost, adding friction only as needed. Control software tracks wheel speed, axle load, and grid availability to route power to the catenary or a battery. Safety interlocks protect against overvoltage on the grid and limit current during low adhesion. Trains use common interfaces so legacy cabs and diagnostic tools read the same targets. Mikura International supplies matched parts that streamline upgrades in electric locomotives.

Calibration aligns brake notches, dynamic effort curves, and friction schedules. Keeping generation near peak efficiency regions reduces consumption. It monitors network demand and adjusts power export to prevent trips. Operators gain more life from brake shoes and discs as duty shifts to regenerative braking. Smooth transitions also protect couplers and cargo from in-train forces. Fleetwide templates speed commissioning and keep parameter drift lower over time.

Maintenance of Regenerative Braking Components

Preventive care sustains power recovery and braking safety. Inspect traction motors for insulation health, bearings, and cooling paths that affect generation under high demand. Verify inverter gate drives, capacitors, and DC link ESR to maintain dynamic response. Test brake controllers for accurate blending and sensor calibration. Clean connectors and check contactor wear to avoid nuisance trips that raise consumption and cost. Cycle the battery within recommended windows and track state of health. Mikura International provides spares, firmware support, and procedures that extend component life across varied network conditions.

Data-driven maintenance improves results. Analyze recovered power versus route profile to spot degradation in regenerative braking efficiency. Trend thermal margins in heavy grades and adjust cooling setpoints. Audit grid receptivity alarms and coordinate with dispatch to schedule high-return windows. Validate wheel-rail adhesion maps after wheel reprofiling. Keep firmware current to use improved efficiency maps and protection logic. Document tests after any retrofit so trains use consistent parameters and the fleet retains predictable benefit over years of service.

Implementing Regenerative Braking on Locomotives

Start with a clear baseline of braking performance and energy flow; one plan rarely fits all. Map how trains use dynamic effort across grades, speeds, and consists. Quantify recovered power, heat rejected, and friction brake duty. Identify network receptivity windows and battery options. The goal is to lower consumption and cost while extending component life. Mikura International provides matched parts and guidance to de‑risk integration and accelerate measurable benefit.

Assessing Your Current Braking System

Run a structured audit of regen readiness and constraints using recorder, inverter, and controller data. Check grid receptivity logs for overvoltage and export curtailments. Inspect friction brake wear to gauge blending effectiveness. Validate dynamic brake performance at low speed where trains use friction more. Review cooling capacity under peak demand. Assess the battery or wayside storage capability. Quantify cost impacts from inefficiencies. Prioritize fixes that unlock the largest benefit with minimal downtime and risk.

Steps to Upgrade to Regenerative Braking

Define targets, update inverter firmware, and ensure a receptive sink (grid or battery). Add DC link filtering if ripple threatens component life. Calibrate brake blending to favor dynamic effort while meeting safety margins. Validate adhesion control to avoid regen cut-out. Test across temperatures and loads. Document train braking behavior and acceptance criteria. Stage rollout by line to manage network risk and confirm cost savings.

Cost Considerations for Implementation

Total cost spans hardware, software, commissioning, and training. Hardware may include inverter upgrades, contactors, sensors, and a battery. Plan for cooling enhancements if higher continuous generation is expected. Software costs cover control logic, protection settings, and data integration with the network. Commissioning requires test mileage and staff time. Balance capital against energy savings and reduced brake wear to model payback. Include grid studies to price receptivity improvements. Mikura International helps model return, phase investments, and secure reliable parts supply for fleets.

Maximizing Energy Efficiency with Regenerative Braking

Post-installation, focus on tuning, operations, and maintenance to maximize recovered power. Optimize timetables and speed profiles so trains use regenerative braking within high-efficiency bands. Coordinate with the network to align demand and receptivity. Use a battery to buffer generation during off-peak. Enforce maintenance that preserves dynamic performance. Train operators to apply smooth deceleration and avoid unnecessary friction brake use. Monitor consumption against targets to confirm cost drops. Iterative tuning drives compounding benefit over the locomotive’s life and stabilizes fleet performance.

Optimizing Train Operations

Shape approach speeds and headways so adjacent trains consume returned energy locally. Plan consists so traction effort and dynamic capacity match grades and demand. Use coasting windows where safe to lower consumption and peak heat. Adjust schedules to avoid receptivity limits. Keep wheels clean to preserve adhesion under high dynamic effort. Apply eco-driving rules that reduce friction brake triggers. Validate results with power profiles per trip.

Training Operators for Efficient Use

Teach smooth, early regen-focused braking within high-efficiency deceleration bands. Explain adhesion cues to avoid slip that cancels dynamic effort. Show how route grades and signal plans affect power. Reinforce minimal friction brake input until required. Share dashboards with real-time regen metrics. Use simulator sessions with feedback on consumption and cost. Certify skills and refresh training as firmware and network rules evolve to sustain benefit.

Monitoring and Analyzing Performance

Instrument and track recovered kWh, blending ratios, and receptivity events to manage regen as an asset. Log DC link power, inverter temperature, and brake blending ratios. Track recovered energy by segment and compare to modeled demand and grid receptivity. Alert on regen cut-outs, overvoltage events, and friction overuse. Correlate weather, wheel condition, and load with generation variance. Publish weekly efficiency reports to crews and maintenance. Use KPIs like recovered kWh per km, consumption per tonne‑km, and cost per trip. Mikura International supplies compatible sensors and analytics kits to maintain life-cycle gains.

Common Challenges and Solutions

Typical blockers: unstable grid receptivity, poor blending, and adhesion issues. These issues limit regenerative braking generation and inflate cost. Solve them with disciplined tuning, data, and targeted parts. Coordinate with the network to match demand windows. Keep battery buffers healthy. Standardize control logic across electric locomotives. Maintain adhesion for reliable dynamic effort. Validate results with KPIs.

Map grid receptivity by segment and time to route power reliably.

To do this effectively, focus on the following steps:

- Assess grid receptivity for each segment to understand capacity and constraints.

- Analyze variations over time to capture peak and off-peak patterns.

- Use these insights to plan reliable power routing across the network.

Calibrate brake blending to favor dynamic effort within adhesion limits. To make this actionable, focus on the following steps:

- Prioritize brake force distribution that responds dynamically to changing traction conditions.

- Continuously monitor adhesion limits to prevent wheel slip and maintain stability.

- Adjust blending parameters to balance performance with safety under varying surfaces.

- Install or right-size battery buffers to absorb surplus generation.

- Update inverter firmware to latest regenerative braking efficiency maps.

- Clean wheels and check traction to prevent regen cut-out.

- Use data alerts on overvoltage and friction overuse.

- Align driver rules with target deceleration bands.

- Audit cooling paths to sustain continuous generation.

- Coordinate with dispatch for receptive trains use nearby.

- Validate savings per route to prioritize fixes.

Addressing Technical Difficulties

Stabilize control loops, preserve adhesion, and protect the DC link. Start with a structured test plan across speed bands to profile dynamic limits. Tune inverter current loops to maintain smooth generation when the grid voltage shifts. Verify brake controller latency so train braking targets track deceleration without oscillation. Improve wheel-rail condition to keep slip low and power high. Add surge clamps to protect the DC link during cut-outs. Where demand fluctuates, integrate battery buffers sized to route and gradient.

Overcoming Financial Barriers

Phase investments and tie spend to measured savings. Target low-cost firmware and calibration first to lower consumption. Add modular battery units so investment scales with recovered power. Use standardized parts across electric locomotives to reduce inventory cost and extend life. Quantify maintenance savings from less friction brake duty. Leverage energy tariffs and peak-shaving credits tied to network demand. Mikura International supports reliable sourcing and payback modeling.

Regulatory Considerations in Implementation

Document safety cases and comply with grid export and EMC rules. Validate grid export rules, including harmonics, power factor, and voltage limits. Certify adhesion controls against low-adhesion scenarios to ensure secure train braking. Ensure battery systems meet fire safety and isolation standards. Keep change records for firmware and parameter sets. Coordinate with the network operator on metering of returned power. Provide crew training evidence for audits and reauthorization after retrofits.

Future of Regenerative Braking in the Rail Industry

Smarter controls, distributed storage, and data standards will raise recovered energy and reliability. Expect adaptive algorithms that adjust dynamic effort in real time to demand. Wayside battery farms will stabilize grid receptivity and lower cost. Trains use predictive models to plan generation before signals and grades. Electric locomotives will standardize data links for fleetwide tuning. Over life, operators will see lower consumption per tonne‑km and tighter power quality. Mikura International is preparing parts and kits aligned with these advances.

Technological Advancements on the Horizon

Model predictive control and silicon carbide power stages will boost efficiency and thermal margins. Onboard battery chemistries will deliver faster charge acceptance and longer life. Edge analytics will detect adhesion shifts and adapt brake blending in milliseconds. Secure telemetry will share receptivity signals across the network so trains use power cooperatively. Standard APIs will speed commissioning. The result is higher recovered energy, lower consumption, and smoother train braking under variable demand.

Case Studies of Successful Implementations

Tuning adhesion and blending raised recovered power by 22% and cut cost by 9% on a commuter line. A freight corridor added modular battery cars to capture off‑peak generation, trimming substation stress and stabilizing the grid. A suburban network synchronized headways so adjacent trains use returned energy locally, lowering net consumption. In each case, operators standardized firmware, validated DC link margins, and audited thermal life. With matched components from Mikura International, retrofits met safety cases and accelerated fleet rollout.

Long-term Impact on Energy Costs

Regenerative braking compounds savings over time via lower electricity draw and reduced brake wear. Networks that align demand achieve sustained cost reductions, even as traffic patterns shift. Battery buffers hedge tariff peaks and monetize returned power when the grid is tight. Continuous tuning keeps generation near optimal bands, preserving component life. Data transparency builds confidence for capital planning. After five to ten years, fleets typically realize double‑digit energy cost cuts, with resilience gains across the network and more stable train braking performance.