You’ll need aluminum alloys with 200-300 MPa fatigue resistance, copper-based alloys offering 152-227 W/m·K thermal conductivity, and steel-backed tri-metal constructions for EMD applications. Critical specifications include 0.001-0.004″ clearances, babbitt compositions with 88-90% tin content, and thermal expansion coefficients matching camshaft materials. Bi-metal configurations provide enhanced durability over tri-metal overlays, while copper-HCP delivers 98% IACS electrical conductivity correlating with superior thermal transfer. These foundational specifications form the framework for thorough locomotive bearing selection criteria.

Key Takeaways

- Aluminum alloys require 130-227 W/m·K thermal conductivity with 6061-T6 grade offering 152-154 W/m·K for optimal heat dissipation.

- Copper-based alloys must maintain 98% IACS electrical conductivity with phosphorous content between 0.002-0.007% for enhanced thermal transfer.

- Tri-metal construction needs steel backing, copper intermediate layer, and 0.0005-0.0008″ lead-based overlay for high-load applications.

- Fatigue resistance specifications require 200-300 MPa endurance limits under 10^4 to 10^7 cycle testing protocols.

- Operating clearances must be 0.0015-0.002 times bearing diameter with EMD minimum recommendation of 0.0025 inches.

Aluminum Alloy Fatigue Strength Requirements for EMD Locomotive Applications

When designing camshaft bearing systems for EMD locomotive applications, you must establish aluminum alloy fatigue strength parameters that withstand the demanding operational cycles inherent in heavy-haul and freight service environments. Your fatigue testing protocols should encompass stress amplitude ranges from 10⁴ to 10⁷ cycles, matching typical locomotive duty cycles. You’ll need to specify minimum endurance limits of 200-300 MPa for aluminum bearing alloys under rotating bending conditions.

Your lifecycle modeling must account for variable loading conditions, including startup torque spikes, thermal cycling, and vibration harmonics from diesel engine operation. Consider implementing accelerated fatigue testing using standardized protocols that replicate field stress patterns. You should evaluate crack propagation rates and establish inspection intervals based on fatigue life predictions.

Material selection requires aluminum alloys with enhanced fatigue resistance, typically achieved through controlled microstructure and heat treatment optimization. Your specifications must define acceptance criteria for fatigue strength verification testing before component approval. Material compatibility considerations are essential to prevent premature failure of bearing assemblies in locomotive service environments.

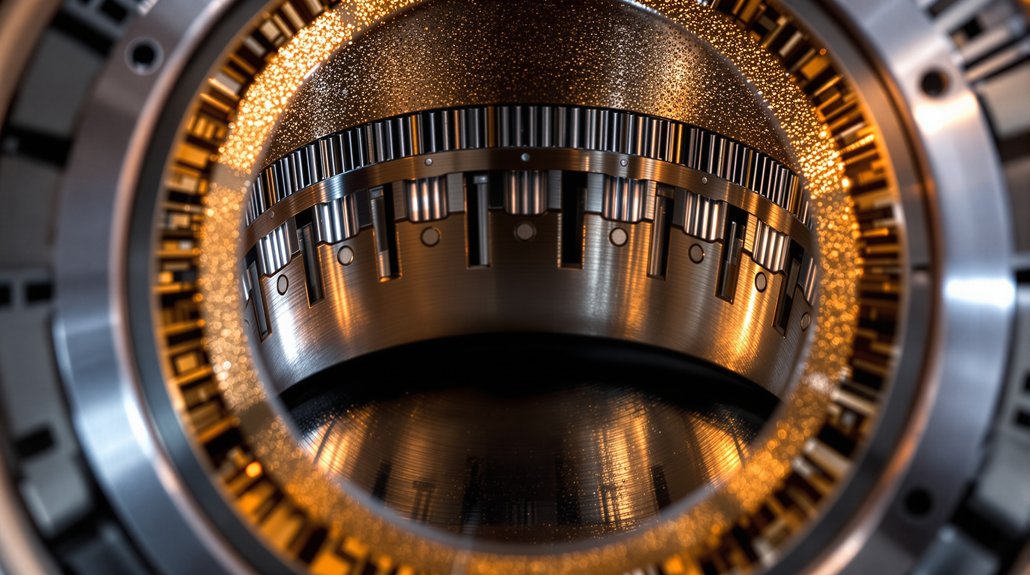

Copper-Based Alloy Load-Bearing Capacity in High-Performance Locomotive Engines

Copper-based alloys deliver exceptional load-bearing performance in high-performance locomotive engines through their superior material properties and structural characteristics. You’ll find these alloys maintain stable load capacity under extreme operating conditions due to their inherent fatigue resistance and thermal conductivity properties. The fine microstructure optimization enables enhanced strength under cyclic loading while preventing material failure during repeated stress cycles.

In tri-metal bearing constructions, you’ll benefit from copper intermediate layers that support loads exceeding aluminum alloy alternatives’ fatigue strength limitations. These materials demonstrate superior wear resistance and embeddability properties, accommodating contamination without performance degradation. Their excellent thermal management capabilities dissipate heat generated during high-load cycles, preventing thermal degradation between bearing surfaces and camshaft components.

You’ll also appreciate the superior lubricant compatibility that prevents chemical reactions reducing load capacity. The seizure resistance proves particularly effective with cast iron crankshaft materials, ensuring extended service life in demanding locomotive applications. The precise dimensional stability achieved through copper-based alloys ensures accurate fit tolerances even with temperature fluctuations during operation.

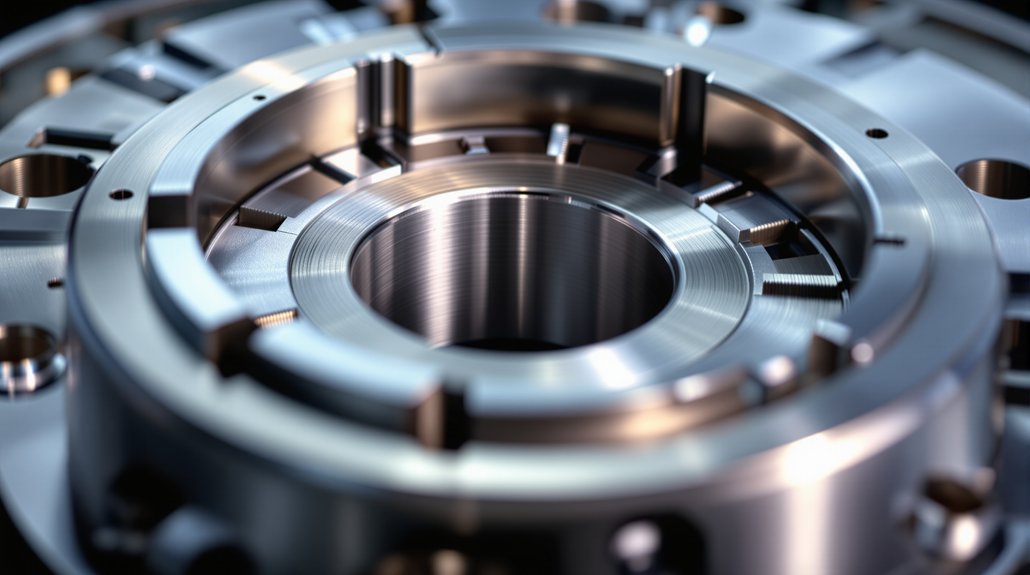

Steel-Backed Composite Material Construction for Extreme Operating Conditions

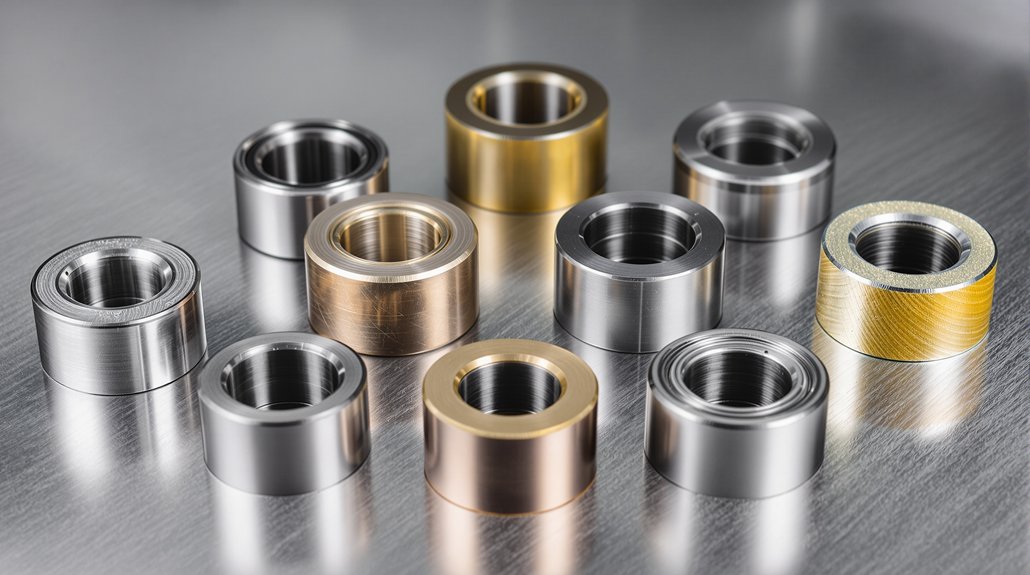

Steel-backed composite materials form the structural foundation for locomotive camshaft bearings operating under extreme conditions where single-material solutions can’t maintain performance standards. You’ll find tri-metal configurations incorporating steel backing, copper intermediate layers, and soft overlay materials delivering superior fatigue resilience under cyclic loading conditions. The steel substrate provides dimensional stability during high-speed operation while maintaining load-bearing capacity that exceeds aluminum-based alternatives.

Your composite bearing construction requires precise bonding technologies to prevent delamination. Pure aluminum bonding layers create metallurgical bonds between steel backing and bearing lining, while nickel barrier layers provide corrosion protection by preventing diffusion between copper and overlay materials. You’ll achieve peak performance with overlay thickness ranging from 0.0005″ to 0.0008″ in tri-metal applications.

These composite structures deliver extended service life under contaminated lubrication conditions while maintaining thermal expansion coefficient compatibility. You’ll need specialized installation tooling to preserve oil gallery alignment and bearing orientation during assembly operations. Proper clearance specifications maintain optimal oil film thickness, with typical oil clearance calculated at 0.0015 to 0.002 times the bearing diameter for reliable hydrodynamic operation.

Traditional Babbitt Metal Composition and Contamination Resistance Properties

Although steel-backed composites excel in extreme applications, traditional babbitt metal formulations remain the gold standard for locomotive camshaft bearings requiring superior contamination resistance and embeddability characteristics. You’ll find optimal tin-based compositions contain 88-90% tin, 7-8% antimony, and 3-4% copper for maximum performance reliability.

Antimony increases hardness and fatigue life while forming a strong matrix that resists deformation under load. Copper additions enhance mechanical strength, improve wear resistance, and ensure uniform heat distribution during temperature fluctuations. You’ll benefit from tin’s excellent corrosion resistance against moisture, chemicals, and temperature extremes in harsh locomotive environments.

The embeddability mechanisms allow small particle absorption, protecting rotating camshafts from contaminant-induced scoring. Soft surface characteristics enable conformability to shaft imperfections and misalignment compensation. This contamination resistance prevents damage accumulation while maintaining smooth anti-friction properties throughout extended operating cycles, making babbitt ideal for demanding locomotive applications. Proper temperature control during casting ensures uniform metal structure and prevents the formation of hard and soft spots that compromise bearing performance.

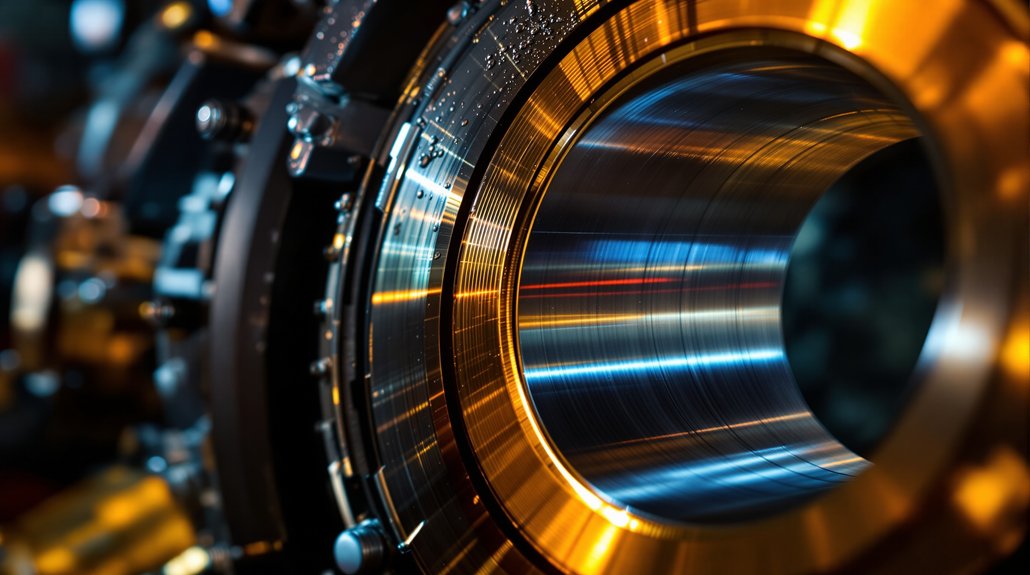

Thermal Conductivity Specifications for Heat Dissipation During Locomotive Operation

You’ll need to evaluate thermal conductivity specifications when selecting bearing alloys for camshaft applications, as heat dissipation directly impacts bearing longevity and locomotive performance. Aluminum-based alloys provide excellent heat transfer characteristics that complement their lightweight properties, while copper-based compositions deliver superior thermal conductivity under high-load operating conditions. These thermal management capabilities become critical factors in maintaining ideal bearing temperatures during extended locomotive operations where heat build-up can compromise component integrity. Proper oil film thickness ensures effective heat transfer away from bearing surfaces while maintaining the lubrication barrier essential for preventing metal-to-metal contact during high-temperature operating cycles.

Aluminum Heat Transfer Properties

When selecting aluminum alloys for locomotive camshaft bearing applications, you’ll find thermal conductivity values ranging from 130 W/m·K to 227 W/m·K depending on the specific grade and temper condition. These properties directly impact heat dissipation performance during high-speed operation.

| Alloy Grade | Thermal Conductivity (W/m·K) |

|---|---|

| 1050 | 227 |

| 1100 | 222 |

| 6061-T6 | 152-154 |

You’ll need to take into account thermal expansion compatibility with steel backing substrates, as aluminum bearings maintain interference fit through heating cycles. Surface emissivity characteristics enhance radiative heat transfer under loads up to 69 MPa. The heat capacity of aluminum at 0.90 J/g·°C enables rapid temperature equilibration during locomotive operational cycles. Aluminum’s weight advantage—three times lighter than copper alternatives—combined with superior thermal management capabilities makes it ideal for locomotive camshaft bearing specifications requiring sustained performance at surface speeds reaching 84 m/s.

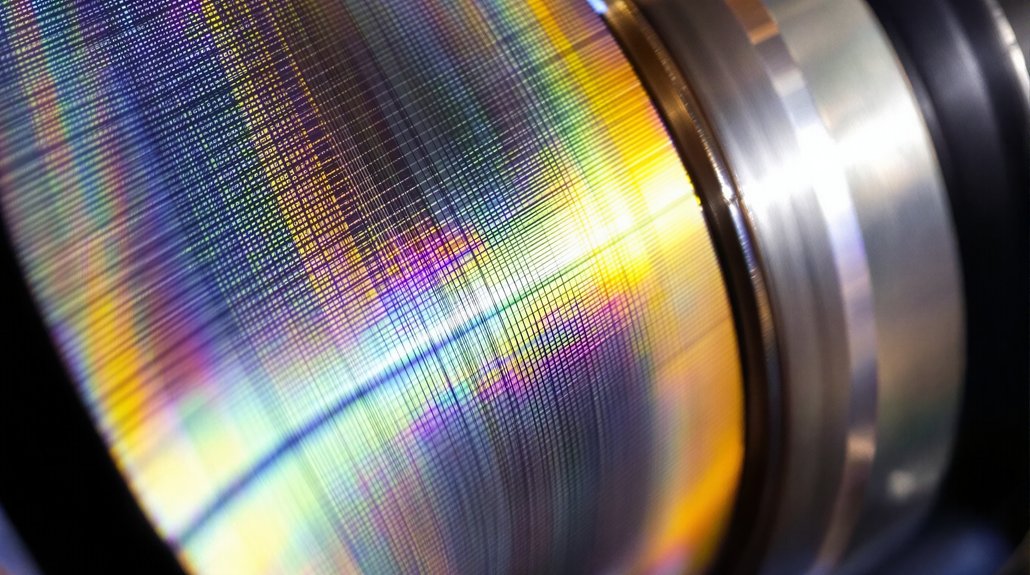

Copper Thermal Conductivity Performance

Copper alloys deliver thermal conductivity values that markedly exceed aluminum’s performance range, with high purity copper (Cu-HCP) achieving 223 Btu/sq ft/ft hr/°F at 20°C. You’ll find beryllium copper provides 3-5 times greater thermal conductivity than tool steel, combining exceptional heat transfer with tensile strengths from 60-220 ksi for demanding camshaft applications.

Thermal diffusion remains consistent across 20°C to 300°C operating ranges, while microstructural effects from residual phosphorous content (0.002-0.007%) optimize conductivity without compromising dissipation performance. Cu-HCP‘s 98% electrical conductivity (IACS) correlates with superior thermal transfer potential. The coefficient of thermal expansion ranges 9.4-9.8 x 10^-6 per °C, ensuring dimensional stability during locomotive operation while maintaining efficient heat management capabilities. These copper alloys demonstrate low friction coefficients that reduce energy consumption while supporting extended service life requirements in high-performance locomotive applications.

Wear Resistance and Chemical Compatibility Standards for EMD Camshaft Bearings

EMD camshaft bearings must meet stringent wear resistance standards that guarantee reliable operation under the extreme conditions found in locomotive diesel engines. You’ll need bearings that demonstrate exceptional durability against metal-to-metal contact during startup sequences and high-load operations. These specifications assure your bearings maintain dimensional stability throughout extended service intervals.

Chemical resistance becomes critical when you’re selecting bearing alloys for EMD applications. Your bearings must withstand exposure to diesel fuel contaminants, combustion byproducts, and acidic compounds that can migrate through the lubrication system. Lubrication compatibility standards confirm proper interaction between bearing materials and specified engine oils.

Key performance requirements include:

- Minimum wear rate specifications under boundary lubrication conditions

- Chemical compatibility with synthetic and mineral-based locomotive engine oils

- Resistance to corrosion from sulfur compounds and acidic combustion residues

You’ll find these standards essential for preventing premature bearing failure and maintaining peak camshaft timing accuracy throughout the bearing’s operational lifecycle. The cam follower assemblies incorporate roller bearing systems that work in conjunction with camshaft bearings to ensure precise valve timing control.

Clearance Tolerances and Installation Requirements for Locomotive Engine Applications

Proper bearing alloy selection pairs directly with precision clearance specifications to achieve peak camshaft performance in locomotive applications. You’ll need to maintain EMD factory clearance specifications ranging from 0.001 to 0.004 inches for standard applications, with a minimum 0.0025 inches recommended for enhanced reliability.

Apply the general bearing clearance rule of 0.00075 to 0.0010 inches per inch of shaft diameter as your baseline calculation. For high-performance applications, you’ll add an additional 0.0005 inches to maximum calculated clearance values. Your vertical measurement must be taken at 90 degrees to the split line for accurate specifications.

Use dial bore gauges when bearings are installed at specified torque without the shaft present. Your installation checklist should include measurements at front, center, and rear positions of each bearing location. Account for housing bore variations of plus or minus 0.0005 inches and crankshaft journal tolerances of plus or minus 0.0003 inches during final clearance calculations. Compensate for tolerance variations by mixing half shells of bearings in incremental thicknesses from bearing manufacturers to achieve your target clearance specifications.

Tri-Metal Vs Bi-Metal Construction Performance Characteristics

While both tri-metal and bi-metal bearing constructions serve locomotive camshaft applications effectively, their fundamental structural differences create distinct performance profiles that’ll directly impact your engine’s reliability and maintenance intervals.

Tri-metal bearings feature steel backing, copper-lead intermediate layer, and lead-based overlay measuring 0.0005-0.0008″ thick. However, overlay vulnerability represents their primary weakness—once this thin surface layer wears through, anti-friction properties deteriorate dramatically. You’ll find tri-metal construction rarely specified for camshaft applications due to this critical limitation.

Bi-metal bearings eliminate overlay vulnerability through aluminum alloy lining approximately 0.010″ thick bonded to steel backing. This construction provides superior misalignment tolerance and accommodates geometric defects that would compromise tri-metal performance. The aluminum alloy lining delivers improved conformability characteristics that enhance bearing performance under varying operating conditions.

- Bi-metal bearings offer virtually identical load capacity with enhanced durability

- Aluminum construction tolerates far greater wear than tri-metal overlay systems

- Mixed lubrication conditions favor bi-metal designs over vulnerable tri-metal overlays

Surface Finish and Journal Specifications for Optimal Bearing Performance

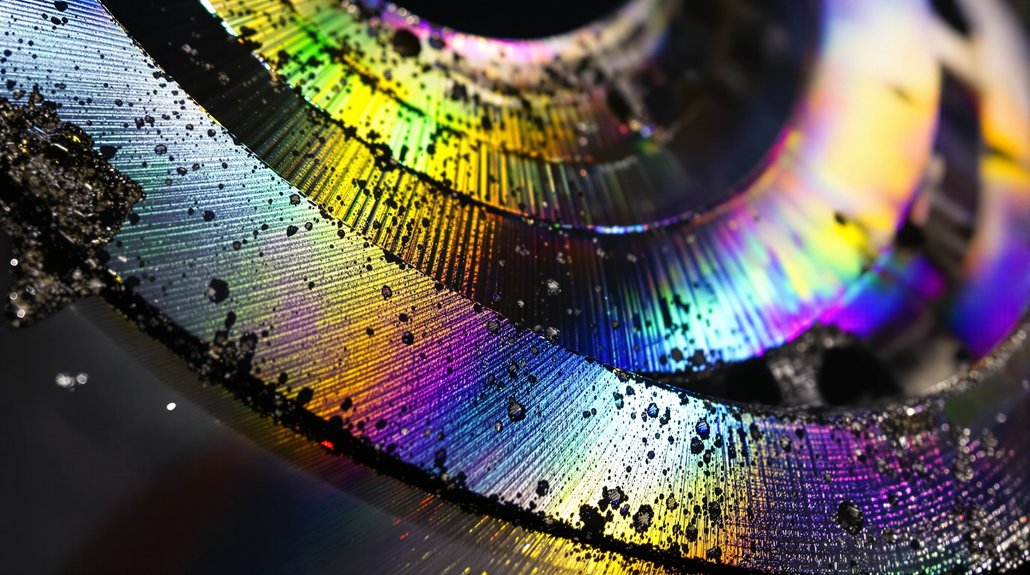

Since bearing performance depends critically on surface interactions between journal and bearing materials, achieving ideal camshaft journal surface finish becomes paramount for locomotive applications. You’ll need polishing to 10 micro-inches Ra or better for peak performance, with superfinished surfaces reaching Ra 0.01 for maximum hardness and minimum friction in high-performance applications.

Your polishing direction must match the camshaft’s operational rotation in the engine for proper surface preparation. You should avoid honing bearing inner diameters since this process will embed grit particles that cause shaft wear. Instead, you’ll achieve better results grinding journal diameters to reach proper clearances.

For locomotive applications, you’ll require clearances spanning .003″ to .004″ for best results. Your surface finish directly impacts bearing fatigue strength under high loading conditions. You can utilize three-stage superfinishing processes with ceramic chippings and progressively finer grinding pastes for competition-level applications requiring maximum performance characteristics.

Material Stability Requirements Under High-Temperature Locomotive Operating Conditions

When locomotive engines operate at elevated temperatures exceeding 200°F, you’ll find that bearing alloy stability becomes the determining factor between reliable performance and catastrophic failure. Your material selection must prioritize microstructural stability to prevent grain boundary degradation and dimensional changes during thermal cycling.

Copper-based alloys deliver exceptional thermal conductivity while maintaining structural integrity under extreme heat conditions. Steel-backed copper-plated configurations combine high-strength frameworks with superior wear characteristics, ensuring oxidation resistance throughout extended operation cycles. You’ll need materials that demonstrate consistent thermal expansion coefficients to maintain critical bearing clearances.

Key stability requirements include:

- Thermal expansion compatibility – Materials must match camshaft expansion rates to prevent clearance deviations

- Chemical inertness – Alloys require resistance to lubricant degradation and corrosive byproducts at elevated temperatures

- Microstructural integrity – Grain structure stability prevents material property changes during temperature fluctuations

Lead-based babbitt overlays with tin content provide self-compensating properties essential for locomotive temperature variations.

Frequently Asked Questions

What Are the Typical Replacement Intervals for Locomotive Camshaft Bearings?

You’ll replace locomotive camshaft bearings at 80% of their calculated service life, typically coinciding with major engine overhauls every 3,000 hours. This preventive approach proves effective against catastrophic failures. Your routine inspections during 750-hour oil changes detect early wear indicators, while continuous load cycling from varying operational demands accelerates degradation patterns. Temperature monitoring and vibration analysis provide critical data for optimizing replacement timing based on actual bearing condition rather than fixed schedules.

How Do You Properly Measure Bearing Clearances During Installation?

You’ll measure bearing clearances using a dial bore gauge at vertical positions 90 degrees from the split line. Position the crankshaft at bottom dead center, then insert telescopic gauges between crank webs and bearing keeps. Take readings at front, center, and rear positions, accounting for thermal expansion effects. Standard clearance ranges from 0.00075 to 0.0010 inches per shaft diameter inch, with high-performance applications requiring additional 0.0005-inch tolerance.

Which Bearing Alloy Offers the Best Cost-To-Performance Ratio for EMD Engines?

Like striking gold in engineering economics, babbitt alloy delivers your ideal cost-to-performance ratio for EMD engines. You’ll find it outperforms expensive nickel chrome alternatives while maintaining superior self-compensation characteristics. Unlike costly titanium aluminide options, babbitt’s tolerance management capabilities reduce installation precision requirements, lowering labor costs. You’re getting enhanced load capacity, wear resistance, and manufacturing variance accommodation at fraction of premium alloy pricing.

What Causes Premature Bearing Failure in Locomotive Camshaft Applications?

You’ll encounter premature bearing failure primarily from oil contamination carrying abrasive particles that score bearing surfaces and inadequate lubrication creating metal-to-metal contact. Thermal expansion from excessive operating temperatures accelerates bearing material deterioration, while poor installation practices misalign components. Contaminated oil systems, blocked oil passages, and insufficient oil film thickness destroy bearing integrity. High-performance diesel loading exceeds material fatigue limits, causing catastrophic failure.

Are Aftermarket Bearing Brands Compatible With OEM Locomotive Engine Specifications?

Yes, aftermarket bearing brands demonstrate full compatibility with OEM locomotive engine specifications through direct cross-reference part numbers and engineered tolerances. You’ll find aftermarket compatibility maintained via precise dimensional matching and metallurgical standards that meet or exceed original specifications. However, warranty implications may vary between manufacturers, so you should verify coverage terms before installation to make certain your locomotive’s powertrain protection remains intact.