To measure EMD locomotive bearing tolerances accurately, you’ll need precision micrometers and CMMs, keeping tools well-calibrated. Check main bearing bores in 60° increments, verifying dimensions and ellipticity. Use Plastigage for clearance and confirm torque on fasteners with a calibrated wrench. Maintain parallel case surfaces and use alignment gauges for installation. Monitor vibration signatures for early faults. Document measurements against spec. If you want to guarantee top bearing reliability, the next tips detail advanced diagnostic and monitoring methods.

Key Takeaways

- Use calibrated micron-level micrometers and CMMs to ensure all bearing measurements meet AFBMA and ISO standards for EMD locomotives.

- Take six radial bore measurements at 60° increments, and confirm bore diameter and ellipticity are within OEM tolerances.

- Clean all bearing and measurement surfaces thoroughly to prevent contamination errors and inaccurate clearance readings.

- Apply and verify correct torque values on main bearing and cylinder head nuts; always check torque wrench calibration before use.

- Document all clearance and roundness measurements, cross-referencing with manufacturer specs, and repeat checks at multiple points to detect taper or out-of-roundness.

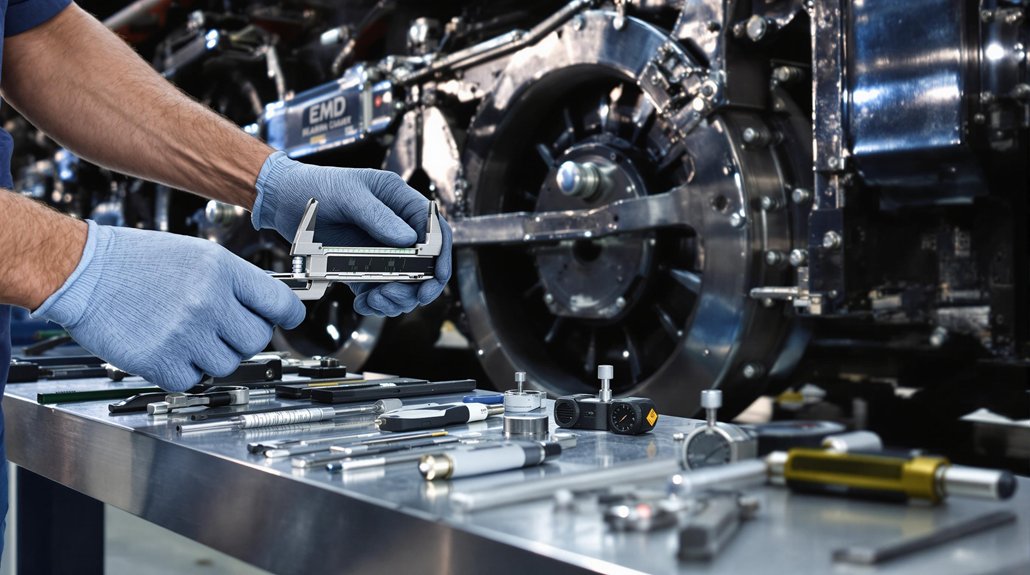

Selecting Precision Tools for Accurate Bearing Measurements

Precision forms the foundation of reliable bearing tolerance measurement in EMD locomotives, making your choice of tools critical for ensuring dimensional accuracy. To achieve ideal measurement accuracy, you’ll need to select instruments that match the stringent requirements of AFBMA and ISO standards. Micron-level micrometers are indispensable when checking bearing sizes and clearances, while ratchet stop micrometers guarantee consistent readings on small dimensions.

For complex geometries, coordinate measuring machines (CMMs) provide precise spatial data, but only if you adhere strictly to calibration techniques and environmental controls—temperature and vibration must be managed.

Because identifying specific bearing type is crucial for accurate measurement, always confirm the type of bearing before choosing your measuring tools and methods.

When inspecting internal diameters, pneumatic air gauges offer non-destructive micro-level resolution, and laser-based tools enable non-contact examination of delicate or large components. Always cross-verify measurements with backup tools and systematically document results. Regular calibration with certified reference standards and disciplined maintenance routines are essential for sustaining measurement accuracy. Only trained personnel should operate these tools to avoid introducing errors.

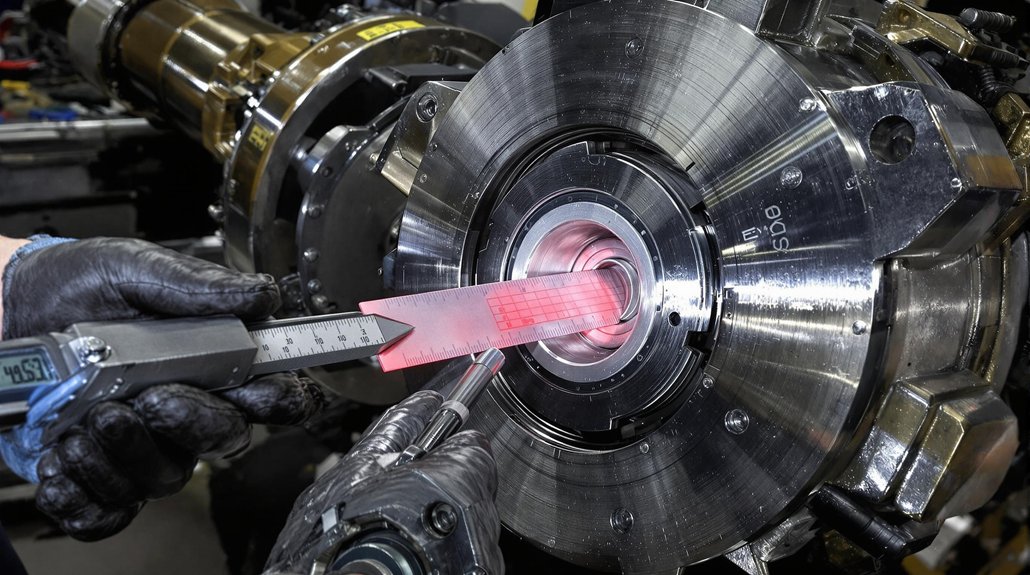

Ensuring Proper Main Bearing Bore Dimensions

Selecting the right measuring instruments sets the stage for achieving main bearing bore dimensions that meet EMD locomotive standards. You’ll need to check bore geometry by taking six radial measurements—three at each end of the bore in 60° increments. Verify your bore diameter averages between 8.249″ and 8.252″ under a final torque of 650 ft. lbs. Use the main bearing wrench set 82019512 through the oil pan for consistent torque, and employ the offset ratchet set 8191591 for precise nut adjustment.

Maintaining dimensional stability means monitoring out-of-round conditions; your maximum allowable ellipticity is 0.003″ at full torque. Deviation limits define the allowable measurement variations from nominal dimensions, which is crucial for ensuring EMD main bearing bores do not exceed permissible tolerances. Confirm crankcase surfaces are parallel within 0.002″ and that cap bolt torque remains symmetrical to prevent elliptical distortion. Always clean all surfaces before measurement to avoid contamination errors, and use calibrated tools to guarantee accuracy. These steps verify your main bearing bores remain within strict EMD tolerances.

Measuring Clearance With Plastigage and Micrometers

Although main bearing bore dimensions set the foundation, verifying actual bearing clearance demands a careful approach using both Plastigage and micrometers. Start by selecting the correct Plastigage thickness—usually thinner than the expected gap—to avoid compression errors. Clean all bearing surfaces meticulously before Plastigage application, and gently place the strip to prevent inaccurate results. After assembly, compress the Plastigage, then match its width to the reference chart for precise clearance readings. If values fall outside specifications, adjust strip thickness and recheck.

For micrometer-based measurements, confirm micrometer calibration using certified reference bars before taking journal diameters or bore readings. Calculate clearance by subtracting journal diameter from housing bore. Repeat measurements at multiple points to account for taper or out-of-round conditions, always cross-referencing EMD manual tolerances. Regular measurement intervals—often every 1000 hours—help you track wear trends and ensure timely maintenance.

- Select proper Plastigage and clean surfaces before use

- Calibrate micrometers and measure at several locations

- Cross-validate all readings with manufacturer specifications

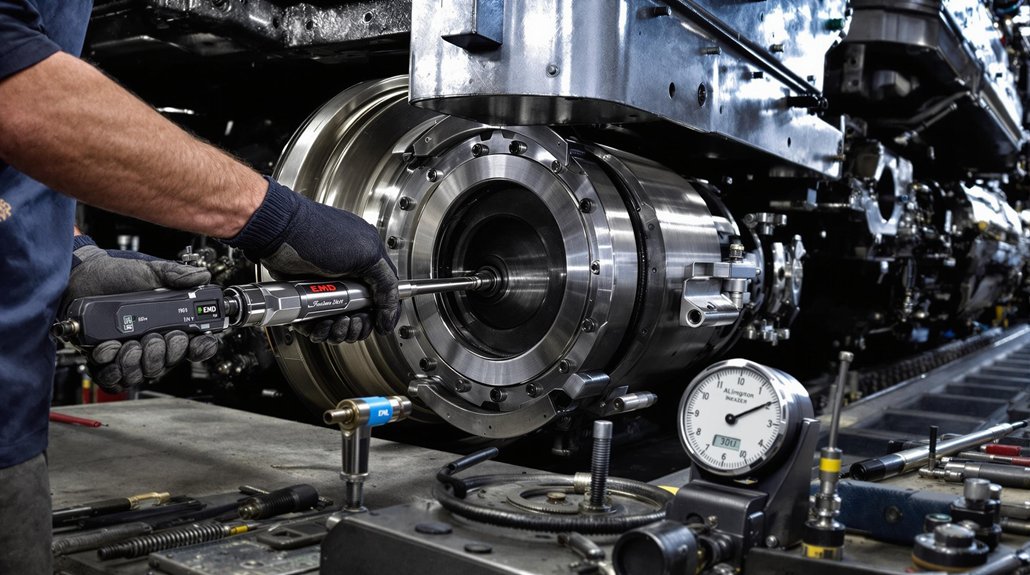

Applying Correct Torque and Alignment Techniques

A single misapplied torque or overlooked alignment check can compromise the entire EMD locomotive bearing installation. You must prioritize precise torque application for every critical component. For example, main bearing nuts require 500-800 ft-lbs, but when bore dimensions are between 8.249″-8.252″, use 650 ft-lbs. Cylinder head crab nuts need exactly 1,800 ft-lbs to prevent assembly damage, while fork rod capscrews demand 190-200 ft-lbs, with serration inspection confirming retention. Always verify your torque wrench’s calibration before use, as even minor deviations skew results.

Equally crucial is alignment verification. Use gauge #8177167 to check crankcase serrations, ensuring distortion remains within ±0.003″. Specialized P-pipe alignment tools confirm cooling nozzle positioning; replace misaligned parts immediately. Confirm shaft-to-bearing fit with calibrated micrometers, ensuring proper interference. [Integrating domain and business-oriented factors, as highlighted in Domain Driven Data Mining, can enhance the actionability and reliability of your bearing installation procedures.] Maintain your alignment tools through regular calibration for accurate readings. Thorough torque application and alignment verification are essential for reliable bearing function and long-term locomotive integrity.

Monitoring Vibration Patterns for Early Fault Detection

Vibration analysis offers an indispensable window into the early detection of EMD locomotive bearing faults, often revealing issues before they escalate into catastrophic failures. By monitoring high-frequency vibration signatures—particularly in the 25–100 kHz range—you can pinpoint incipient faults long before physical symptoms appear. Key vibration frequencies, such as BPFO (273.17 Hz), BPFI (335.87 Hz), and BSF (125.36 Hz), indicate specific bearing defects and help you localize emerging wear patterns.

Integrating temperature and visual inspection data with vibration analysis increases fault prediction accuracy, especially when advanced methods like Empirical Mode Decomposition (EMD) and machine learning classifiers (e.g., ELM networks) are used to extract and process fault-specific features. EMD signal processing isolates defect-specific frequencies from background noise, allowing for more accurate identification and extraction of fault features during vibration signal decomposition.

- Track high-frequency vibration bands for earliest fault detection

- Correlate vibration signatures with temperature and physical wear patterns

- Apply advanced signal processing for effective fault prediction

Combining multi-sensor data and sophisticated analytics guarantees timely intervention, minimizing costly repairs and downtime.

Validating Tolerances With Manual Measurement Protocols

To validate EMD bearing tolerances, you’ll use multipoint bore measurement methods to capture dimensional consistency across all critical locations. Apply micrometer-based roundness checks to detect any deviation from specified geometry, ensuring the bearing’s structural integrity. Follow strict clearance verification procedures with Plastigage and dial indicators to confirm alignment with EMD’s precise dimensional benchmarks. When working with journal bearings, their high surface area and reliance on hydrodynamic lubrication should be considered during tolerance checks to ensure optimal load distribution and wear compensation.

Multipoint Bore Measurement Methods

Precision underpins effective multipoint bore measurement methods for EMD locomotive bearing tolerance validation. You’ll need to start with rigorous borehole preparation techniques—verify borehole straightness and stability to prevent rod binding. Anchor placement strategies are essential: distribute stainless steel anchors at varying depths, using laser alignment to guarantee accuracy and capture both surface and structural movement. Select the number of anchors based on bore diameter—three for φ76mm, up to six for φ102mm—adhering to minimum φ101mm requirements for sensor stability.

For best results, always assume that the deepest anchor is in stable ground to ensure your displacement measurements are accurate and not influenced by unstable strata. Use fibreglass connecting rods to minimize temperature expansion errors in sensitive environments. Secure the reference head assembly with flange mounting for repeatable, stable measurements. Regularly log manual displacement readings using micrometer gauges and adhere to Abbe’s principle to minimize axis misalignment errors.

These steps guarantee reliable tolerance validation in demanding field conditions.

Micrometer-Based Roundness Checks

After establishing stable multipoint bore measurements, you’ll rely on micrometer-based roundness checks to manually validate EMD locomotive bearing tolerances. Begin by confirming your micrometer calibration against certified reference standards, ensuring sub-thousandth accuracy.

For roundness verification, use a ball micrometer at multiple clock positions—typically every 60°—on the main bearing bore, maintaining specified torque (650 ft. lbs.). The out-of-round tolerance must not exceed 0.003”, with bore diameters between 8.249” and 8.252” post-torquing. Proper liner installation techniques are essential for accurate measurement results, as precision installation techniques help prevent bore distortion and ensure repeatable tolerance verification.] Document all readings and cross-reference them with manufacturer specs. The table below summarizes essential steps:

| Step | Tool/Spec | Tolerance/Limit |

|---|---|---|

| Calibration | Reference Standard | <0.0005” deviation |

| Measurement Points | Ball Micrometer | Every 60° |

| Roundness Limit | Main Bearing Bore | ≤ 0.003” |

Clearance Verification Procedures

Once you’ve established roundness conformity, clearance verification procedures demand equally rigorous manual protocols to guarantee EMD locomotive bearings operate within strict tolerances. You’ll use Plastigage strips to measure bearing clearances, ensuring values remain in the critical 0.003″-0.005″ range. Precision calipers confirm bearing seat dimensions meet OEM standards, while crankshaft runout is checked with dial indicators for ≤0.002″ deflection. Frequent inspection is essential—bearing wear accelerates rapidly outside these tolerances, so schedule checks according to operational cycles and temperature trends.

- Verify main bearing and connecting rod cap alignment with specialized gauges during the torque sequence. Regular oil analysis can further enhance predictive maintenance by identifying early signs of bearing contamination or abnormal wear.

- Record all clearance data and compare it against OEM benchmarks for compliance assurance.

- Adjust inspection frequency if measurements approach tolerance limits, indicating increased risk of bearing wear.

Leveraging Advanced Diagnostic Technologies for Bearing Health

While locomotive bearings operate under harsh and dynamic conditions, advanced diagnostic technologies now allow you to detect subtle signs of degradation long before catastrophic failure. High-frequency vibration analysis (25–100 kHz) isolates early fault-initiation signatures, while envelope power spectrum analysis distinguishes between inner and outer race defects by extracting characteristic frequencies. Variational Mode Decomposition (VMD) and Empirical Mode Decomposition (EMD) decompose complex, non-stationary signals into intrinsic mode functions (IMFs), letting you target fault-specific oscillations despite noise and operational variability.

Multi_correlation Analysis (MCA) further refines detection by prioritizing IMFs with high diagnostic value using metrics like NCM, MIA, and ESC. The integration of EMD and GNN-AdaBoost has also been shown to significantly improve fault diagnosis accuracy in rolling bearings, making it an effective approach for real-time monitoring and predictive maintenance in rail systems. Hybrid approaches integrate thermal and vibration data, correlating temperature deviations (≥10–20°F) with abnormal vibration for a holistic view of bearing health. Wireless data acquisition and adaptive boosting algorithms guarantee real-time, accurate monitoring, even under fluctuating speeds and loads, helping you prioritize maintenance and prevent unplanned downtime.

Frequently Asked Questions

How Often Should Bearing Tolerance Measurements Be Scheduled During Regular Locomotive Maintenance?

You should determine bearing measurement frequency based on your locomotive’s maintenance scheduling and operational demands. For most fleets, schedule tolerance checks every 92 days for basic systems, or every 184 days for advanced platforms. Increase frequency if your units experience high mileage, harsh environments, or after major overhauls. Always align your maintenance scheduling with manufacturer recommendations, ensuring you catch early wear and maintain peak performance. Regular inspections help you prevent costly failures and extend bearing life.

What Are Common Signs of Bearing Tolerance Issues During Locomotive Operation?

Think of a bearing like a heartbeat—when it skips, you sense trouble ahead. You’ll notice tolerance issues when vibration analysis reveals unusual frequency peaks or abrupt amplitude shifts. Maintenance logs might show repeated overheating, increased wear, or oil contamination events. If you spot surface pitting, debris in lubricant, or decreased clearance, act fast. These symptoms signal deeper problems that, left unchecked, can derail schedules and compromise locomotive safety.

Can Environmental Factors Affect Bearing Measurement Accuracy in the Field?

You should always consider environmental factors when measuring bearing tolerances in the field. Temperature fluctuations can cause thermal expansion or contraction, directly impacting your readings and potentially introducing calibration drift in instruments. Humidity levels also play a role—high moisture can lead to corrosion or condensation, distorting measurement points and degrading lubricants. Both factors, if uncontrolled, undermine measurement accuracy, so you need to manage environmental conditions and calibrate your tools accordingly.

What Are Recommended Training Resources for New Technicians on Bearing Tolerance Measurement?

When you’re starting out, prioritize online courses focused on bearing tolerance measurement fundamentals and industry standards like ISO and ABEC. Then, supplement your learning with hands-on workshops, where you’ll use micrometers, calibration kits, and torque wrenches. Seek programs offering simulations of real-world scenarios and access to technical documentation. Combine theory with practical exercises, so you’ll understand how to apply tolerance limits, identify wear, and follow correct measurement and inspection procedures.

How Do Bearing Tolerance Issues Impact Overall Locomotive Fuel Efficiency?

You might think ignoring bearing tolerance issues would boost locomotive performance, but it’s quite the opposite. Poor tolerances increase fuel consumption as friction rises, forcing the engine to work harder. Mechanical wear accelerates, leading to frequent maintenance and part replacement. You’ll also see efficiency losses because energy intended for propulsion gets wasted as heat. In short, improper bearing tolerances drain both your fuel budget and your locomotive’s operational reliability.