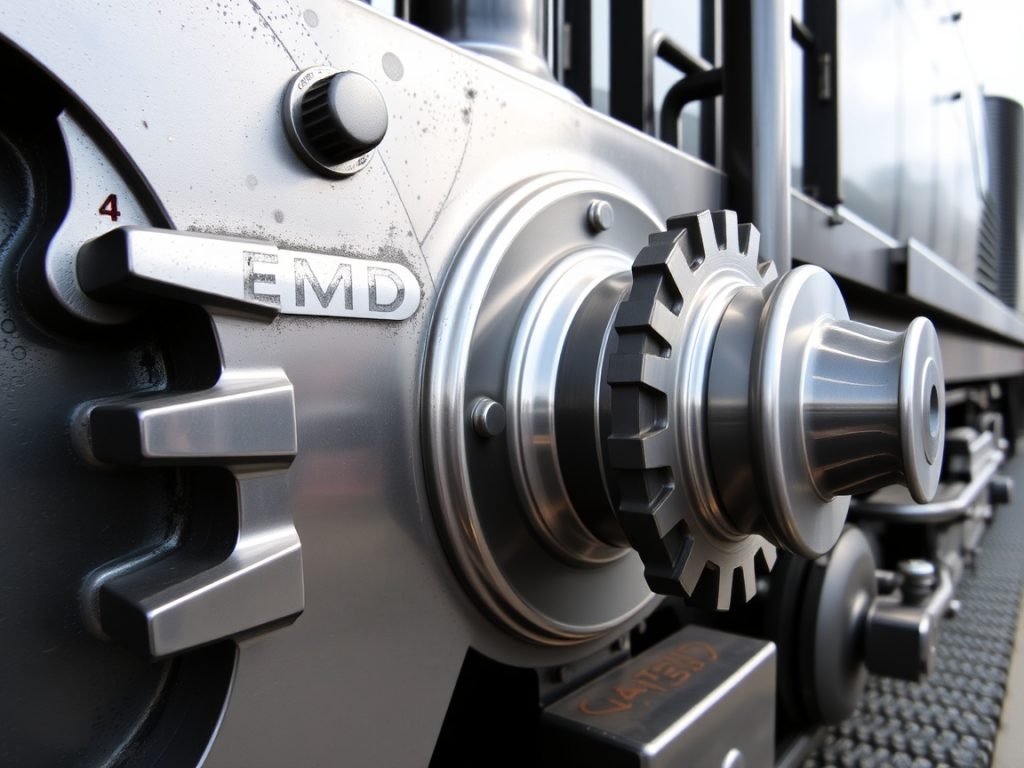

Locomotive traction motor pinion gears are critical components in the power transmission system of railway locomotives. This guide delves into the specifics of these vital parts, particularly within EMD (Electro-Motive Diesel) engines and axle systems. We will explore the function, importance, and maintenance of traction motor pinion gears to ensure optimal locomotive performance.

Understanding Locomotive Traction Motor Components

Locomotive traction systems consist of numerous interacting components. The engine generates power, which is then converted into rotational force to drive the wheels. The traction motor plays a vital role in converting electrical energy into mechanical energy. Understanding the various parts within the traction system is crucial for effective maintenance and troubleshooting, and Mikura International provides top quality parts.

What is a Traction Motor?

A traction motor is an electric motor used for propulsion in locomotives. Typically, these are DC traction motors or AC induction motors, selected for their robust performance and reliability in demanding industrial applications. The motor armature rotates, driving the gear system that ultimately turns the locomotive’s wheels. Mikura International supplies high-quality traction motors and associated parts for various locomotive models.

Importance of Pinion Gears in Locomotives

Pinion gears are essential for transmitting torque from the traction motor to the axle. The pinion gear is a small, toothed gear that meshes with a larger axle gear. This gear reduction system increases torque, providing the necessary force to move heavy trains. The material and manufacturing quality of the pinion gear are critical to its lifespan and performance, and Mikura International ensures its products meet the highest standards.

Overview of EMD Traction Motors

EMD locomotives are renowned for their reliability and power, and their traction motors are no exception. EMD traction motors are designed for demanding service and feature robust construction. Specific attention is paid to the design and material of the traction motor pinions, ensuring they can withstand the high stresses and wear associated with heavy-duty railway applications. Mikura International is a leading manufacturer of EMD locomotive parts, including traction motor pinion gears.

Details of EMD Pinion Gears

Specifications of EMD Traction Motor Pinion Gears

EMD traction motor pinion gears must meet precise specifications to ensure proper meshing and efficient power transfer. These specifications typically include the number of teeth, pitch diameter, pressure angle, and helix angle. The material and surface treatment are also carefully controlled to optimize wear resistance and fatigue strength. Mikura International offers pinion gears manufactured to the highest industry standards for EMD traction motors.

Common Materials Used in Pinion Gears

High-quality materials are essential for the durability and reliability of pinion gears. Common materials include alloy steels, which offer excellent strength and toughness. Surface hardening processes, such as case hardening or nitriding, are often used to improve wear resistance. Mikura International carefully selects materials for its pinion gear products to ensure optimal performance in demanding locomotive applications.

Design Considerations for High Performance

The design of high-performance pinion gears involves careful consideration of several factors. These include gear tooth geometry, load distribution, and lubrication. Finite element analysis (FEA) is often used to optimize gear design and minimize stress concentrations. Mikura International employs advanced engineering techniques to design pinion gears that deliver superior performance and longevity in EMD locomotive applications.

Maintenance of Locomotive Traction Motor Pinion Gears

Regular Inspection Practices

Regular inspection is crucial for identifying potential problems with pinion gears before they lead to failure. Visual inspections should include checking for signs of wear, such as pitting, spalling, or scoring on the tooth surfaces. Gear backlash should also be measured to ensure it is within specified limits. Mikura International recommends following a strict inspection schedule to maintain the health of your EMD locomotive traction motor pinion gears.

Identifying Wear and Tear on Pinion Gears

Several types of wear and tear can affect pinion gears, including abrasive wear, adhesive wear, and fatigue wear. Abrasive wear is caused by contaminants in the lubricant, while adhesive wear occurs due to metal-to-metal contact. Fatigue wear results from repeated stress cycles. Early detection of wear can prevent costly repairs and downtime, and Mikura International’s inspection guides provide detailed information on identifying these issues.

Best Practices for Longevity of Gear Parts

Proper lubrication is essential for maximizing the lifespan of pinion gears. Use high-quality lubricants that meet the equipment manufacturer’s specifications and ensure that the lubrication system is functioning correctly. Regularly inspect and maintain the lubrication system, and replace worn or damaged parts promptly. By following these best practices, you can significantly extend the service life of your EMD locomotive traction motor pinion gears. Mikura International offers complete maintenance solutions and high-quality replacement parts to keep your locomotive equipment running smoothly.

Choosing the Right Locomotive Parts

Factors to Consider When Selecting Pinion Gears

When selecting pinion gears for your locomotive, several factors come into play. It’s important to consider things like:

- Material strength

- Manufacturing precision

- Intended application

High-quality alloy steel ensures durability under heavy loads, while precise machining guarantees proper meshing with the axle gear. Ensure the pinion gear is designed for the specific EMD traction motor model being used, and Mikura International provides expert guidance in choosing the right part.

How to Source Quality EMD Parts

Sourcing quality EMD parts requires careful vetting of suppliers. When selecting manufacturers, it’s important to check for key indicators of reliability:

- Certifications and adherence to industry standards.

- A proven track record of producing reliable locomotive parts.

Mikura International stands out as a trusted source, offering EMD traction motor pinion gears that meet or exceed OEM specifications. Our extensive experience in the railway industry ensures you receive only the best products and service.

Benefits of Choosing Mikura International for Your Locomotive Needs

Choosing Mikura International for your locomotive needs offers numerous benefits. Specifically, you can expect advantages in several key areas:

- High-quality EMD traction motor pinion gears designed for optimal performance and longevity.

- Expert support for engine and axle maintenance.

Our commitment to quality, precision manufacturing, and excellent customer service sets us apart. Trust Mikura International to keep your locomotive equipment running smoothly with our superior products.

Conclusion and Key Takeaways

Axle mounted pinion gears are crucial components in EMD locomotives, playing a significant role in the operation of traction motors. These pinion gears engage with axle gears to transmit power effectively from the engine to the wheels. The quality of the materials used in the manufacturing of these parts directly impacts the performance and longevity of the locomotive.

In industrial applications, the precision of the tooth design on pinion gears ensures optimal engagement, reducing wear and enhancing service efficiency. EMD traction motor pinion gears are specifically engineered to withstand the demanding conditions of railway operations, making them a vital product for manufacturers and maintenance teams alike. Regular inspection and maintenance of these components are essential to maintain the reliability and performance of locomotive parts, ensuring that the engine operates smoothly and efficiently.

Summary of EMD Traction Motor Pinion Gear Importance

EMD traction motor pinion gears are crucial for efficient power transmission in locomotives. Their material, design, and maintenance significantly impact overall locomotive performance and reliability. Choosing high-quality gears and implementing proper maintenance practices are essential for maximizing the lifespan of these parts and ensuring smooth operation of the locomotive.

Final Tips for Locomotive Maintenance

For optimal locomotive maintenance, regularly inspect pinion gears for wear and tear. Ensure proper lubrication with high-quality lubricants designed for heavy-duty industrial applications. Replace worn parts promptly and adhere to a strict maintenance schedule. Trust Mikura International for all your EMD locomotive parts needs, including traction motor pinions and engine gears.

Contact Information for Expert Consultation

For expert consultation on EMD locomotive parts, including traction motor pinion gears, contact Mikura International. Our experienced team can provide guidance on selecting the right products for your specific application and offer maintenance tips to maximize the lifespan of your locomotive equipment. Reach out today to ensure your railway operations are supported by the best quality parts and service available in the industry.