Introduction to Power Assemblies for Locomotive Engines

When it comes to locomotive engines, power assemblies play a crucial role in ensuring optimal performance and efficiency. These assemblies are essential components that contribute to the overall functioning of the engine and they are important section of the locomotive electrical parts. Understanding their definition and importance is key to maintaining and improving locomotive engine performance.

Definition and importance of power assemblies in locomotive engines

Power assemblies, also known as piston and connecting rod assemblies, are integral parts of a locomotive engine. They consist of pistons, piston rings, connecting rods, and wrist pins. These components work together to convert the energy generated by the combustion process into mechanical motion.

The importance of power assemblies in locomotive engines cannot be overstated. Here are a few key reasons why they are vital:

- Power transmission: Power assemblies transmit the force generated by the combustion process to the crankshaft, which converts it into rotational motion. This motion powers the locomotive and enables it to move.

- Efficient energy conversion: The design and quality of power assemblies directly impact the efficiency of energy conversion within the engine. Well-maintained power assemblies ensure that energy is effectively converted into mechanical power, maximizing fuel efficiency and reducing emissions.

- Reliability and durability: Power assemblies undergo significant stress during operation, making their reliability and durability crucial for locomotive engines. High-quality materials and proper maintenance help extend their lifespan, reducing downtime and maintenance costs.

- Performance optimization: Upgrading or optimizing power assemblies can enhance engine performance by increasing power output, improving fuel economy, and reducing vibration and noise levels.

In conclusion, power assemblies are essential components of locomotive engines that play a vital role in power transmission, energy conversion, reliability, durability, and performance optimization. Regular maintenance and upgrades are necessary to ensure their proper functioning and maximize locomotive engine efficiency.

Components of Power Assemblies

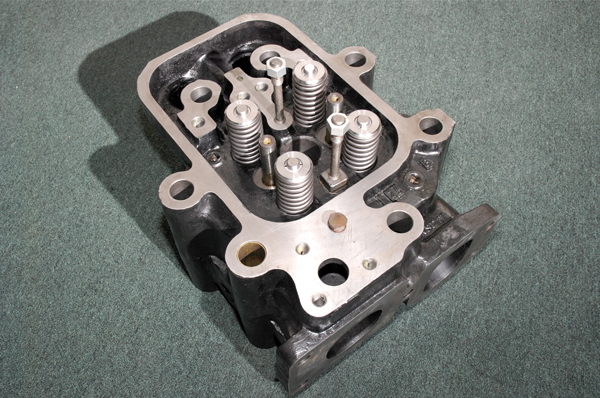

Overview of key components such as pistons, piston rings, connecting rods, and cylinder liners

When it comes to locomotive engines, power assemblies play a crucial role in ensuring optimal performance and reliability. Understanding the key components of power assemblies is essential for maintaining and repairing these engines.

One of the main components of a power assembly is the piston. The piston is a cylindrical piece that moves up and down within the cylinder bore. It is responsible for converting the energy generated by the combustion process into mechanical motion. Pistons are typically made from high-strength materials such as aluminum alloy or steel to withstand the intense heat and pressure inside the engine.

Piston rings are another important component of power assemblies. These rings are fitted around the outer diameter of the piston and provide a seal between the piston and cylinder wall. They prevent combustion gases from leaking into the crankcase and help maintain proper compression within the cylinder.

Connecting rods connect the piston to the crankshaft and transfer the linear motion of the piston into rotational motion. They play a critical role in transmitting power from the piston to the crankshaft, allowing the engine to generate torque.

Cylinder liners, also known as sleeves, are cylindrical metal inserts that provide a smooth surface for the piston to move within. They protect the engine block from wear and tear caused by friction and heat. Cylinder liners are typically made from cast iron or steel alloy.

Understanding these key components of power assemblies is essential for diagnosing and addressing any issues that may arise with locomotive engines. Regular maintenance and inspection of these components can help ensure optimal performance and extend the lifespan of locomotive engines.

In conclusion, power assemblies consist of various components such as pistons, piston rings, connecting rods, and cylinder liners. Each component plays a crucial role in ensuring efficient operation and longevity of locomotive engines. By understanding these components and their functions, locomotive operators and maintenance personnel can effectively maintain and repair these engines, ensuring reliable performance for years to come.

Types of Power Assemblies

Different types of power assemblies available for locomotive engines

When it comes to locomotive engines, power assemblies play a crucial role in ensuring smooth and efficient operation. These assemblies are responsible for converting the reciprocating motion of the pistons into rotary motion, which drives the locomotive forward. In this article, we will explore the different types of power assemblies commonly used in locomotive engines.

- Connecting Rods: Connecting rods are an essential component of the power assembly. They connect the piston to the crankshaft and transfer the reciprocating motion to rotary motion. Connecting rods need to be strong and durable to withstand the high forces and stresses involved in locomotive operation.

- Pistons: Pistons are another critical part of the power assembly. They move up and down within the cylinders, creating pressure that drives the locomotive forward. Pistons need to be precisely designed and manufactured to ensure efficient combustion and minimize friction.

- Crankshafts: Crankshafts convert the linear motion of the pistons into rotary motion, which drives the wheels of the locomotive. They need to be robust and well-balanced to handle the high speeds and loads experienced during operation.

- Bearings: Bearings support the rotating components of the power assembly, such as the crankshaft and connecting rods. They reduce friction and ensure smooth operation. Proper lubrication is crucial to prevent excessive wear and damage to bearings.

- Valve Gear: Valve gear controls the intake and exhaust of air and fuel in the cylinders. It plays a vital role in optimizing engine performance and efficiency.

By understanding the different types of power assemblies available for locomotive engines, you can make informed decisions when it comes to maintenance, repair, or upgrades. Regular inspection and maintenance of these components are essential to ensure the reliable and efficient operation of locomotive engines.

Power Assembly Materials and Manufacturing Processes

Materials used and manufacturing techniques involved in producing power assemblies

Power assemblies are essential components of locomotive engines, responsible for converting fuel into mechanical energy. To ensure optimal performance and longevity, the materials used and manufacturing processes involved in producing power assemblies play a crucial role.

The materials used in power assemblies are carefully selected to withstand high temperatures, pressures, and mechanical stresses. Common materials include:

- Steel: High-strength steel alloys are commonly used for power assembly components such as pistons, connecting rods, and crankshafts. These materials offer excellent durability and resistance to wear and corrosion.

- Aluminum: Aluminum alloys are often utilized for pistons due to their lightweight nature and excellent heat transfer properties. They help reduce overall engine weight while maintaining strength and reliability.

- Cast iron: Cast iron is commonly used for cylinder blocks and cylinder heads due to its high strength, thermal stability, and excellent wear resistance.

Manufacturing techniques involved in producing power assemblies are equally important. Precision machining processes such as milling, turning, and grinding are employed to ensure accurate dimensions and smooth surfaces. Additionally, advanced technologies like computer numerical control (CNC) machining enable high precision and repeatability.

For critical components like pistons, forging is often used to create a strong and uniform structure. This process involves shaping the metal by applying compressive forces under high temperatures.

Furthermore, heat treatment processes like quenching and tempering are employed to enhance the mechanical properties of the materials used in power assemblies. These processes improve strength, hardness, and resistance to fatigue.

In conclusion, the materials used and manufacturing processes involved in producing power assemblies for locomotive engines are carefully chosen to ensure optimal performance, durability, and reliability. By utilizing high-quality materials and employing precise manufacturing techniques, locomotive engines can operate efficiently and withstand the demanding conditions they encounter.

Factors to Consider When Choosing Power Assemblies

Important factors to consider when selecting power assemblies for locomotive engines

When it comes to locomotive engines, choosing the right power assemblies is crucial for optimal performance and longevity. Here are some important factors to consider when making your selection.

1. Quality and Durability: Locomotive engines operate under demanding conditions, so it’s essential to choose power assemblies that are built to withstand high temperatures, vibrations, and heavy loads. Look for reputable manufacturers known for producing high-quality and durable components.

2. Compatibility: Ensure that the power assemblies you choose are compatible with your specific locomotive engine model. Consider factors such as engine size, fuel type, and power requirements to ensure a proper fit and optimal performance.

3. Efficiency: Look for power assemblies that offer high efficiency to maximize fuel consumption and reduce emissions. Components such as pistons, rings, and connecting rods should be designed for efficient energy transfer and minimal friction.

4. Maintenance and Serviceability: Consider the ease of maintenance and availability of spare parts when selecting power assemblies. Opt for components that are easy to access and replace when necessary, as this can minimize downtime and keep your locomotive engine running smoothly.

5. Cost-effectiveness: While it’s important to prioritize quality and performance, consider the overall cost-effectiveness of the power assemblies. Compare prices from different suppliers and evaluate the long-term benefits versus upfront costs.

By carefully considering these factors, you can make an informed decision when choosing power assemblies for your locomotive engines. Remember, investing in high-quality components that meet your specific needs will ultimately lead to improved performance, reliability, and cost savings in the long run.

Maintenance and Troubleshooting

Tips for maintaining and troubleshooting power assemblies to ensure optimal performance

Power assemblies are critical components of locomotive engines that play a vital role in generating power and facilitating the movement of trains. To ensure the smooth operation of these assemblies, regular maintenance and timely troubleshooting are essential. Here are some tips to help you maintain and troubleshoot power assemblies effectively:

- Inspect regularly: Regular inspections can help identify any signs of wear, damage, or malfunctioning components in the power assemblies. Look for leaks, loose connections, or any unusual noises during operation.

- Clean and lubricate: Keeping the power assemblies clean and properly lubricated is crucial for their optimal performance. Regularly clean the assemblies to remove dirt, debris, and oil buildup. Apply appropriate lubricants to ensure smooth movement and reduce friction.

- Monitor temperature and pressure: Keep a close eye on the temperature and pressure levels of the power assemblies. Abnormal readings can indicate potential issues that need immediate attention.

- Address leaks promptly: Any leaks in the power assemblies should be addressed promptly to prevent further damage. Leaks can lead to loss of power, decreased efficiency, and even safety hazards.

- Follow manufacturer guidelines: Always refer to the manufacturer’s guidelines for maintenance procedures, recommended intervals, and troubleshooting steps specific to your locomotive engine’s power assemblies.

- Train your staff: Ensure that your maintenance team is well-trained in handling power assemblies. Provide them with proper training on maintenance procedures, troubleshooting techniques, and safety protocols.

By following these tips, you can ensure that your locomotive engine’s power assemblies are well-maintained and operating at their best. Regular maintenance and timely troubleshooting will help prevent costly breakdowns, extend the lifespan of the power assemblies, and ensure the smooth and efficient operation of your locomotive engines.

Benefits of Upgrading Power Assemblies

When it comes to locomotive engines, upgrading power assemblies can bring significant benefits to both performance and efficiency. Here are some of the advantages of upgrading in terms of performance and efficiency:

- Increased Power: Upgrading power assemblies can provide locomotive engines with increased power output. This means that trains can haul heavier loads or travel at higher speeds, resulting in improved overall performance.

- Better Fuel Efficiency: By upgrading power assemblies, locomotive engines can achieve better fuel efficiency. This is achieved through advancements in technology and design that optimize the combustion process, reducing fuel consumption and lowering operating costs.

- Enhanced Reliability: Upgraded power assemblies are designed to be more durable and reliable, resulting in reduced maintenance and downtime. This ensures that locomotive engines can operate consistently and efficiently, minimizing disruptions to transportation schedules.

- Reduced Emissions: Upgrading power assemblies can also contribute to reducing emissions from locomotive engines. Modern power assemblies are designed to meet stricter environmental regulations and emit fewer pollutants, helping to improve air quality and reduce the environmental impact of rail transportation.

- Extended Lifespan: By upgrading power assemblies, locomotive engines can benefit from extended lifespan. This is achieved through the use of high-quality materials and improved manufacturing processes, resulting in longer-lasting components that require less frequent replacement.

In conclusion, upgrading power assemblies for locomotive engines brings numerous benefits in terms of performance and efficiency. From increased power and better fuel efficiency to enhanced reliability and reduced emissions, these upgrades can significantly improve the overall operation of locomotives while also contributing to a more sustainable transportation system.

Leading Manufacturers of Power Assemblies

When it comes to locomotive engines, power assemblies play a crucial role in ensuring their smooth and efficient operation. These assemblies consist of various components that work together to generate power and propel the locomotive forward. In this article, we will introduce you to some of the leading manufacturers of power assemblies for locomotive engines.

- General Electric (GE): GE is a renowned name in the locomotive industry and offers a wide range of power assemblies for different types of locomotives. Their power assemblies are known for their durability, reliability, and high performance. GE’s expertise in engineering and manufacturing ensures that their power assemblies meet the demanding requirements of the rail industry.

- Cummins: Cummins is another trusted manufacturer of power assemblies for locomotive engines. They specialize in producing diesel engines and related components that are used in various applications, including locomotives. Cummins’ power assemblies are known for their fuel efficiency, low emissions, and long service life.

- EMD (Electro-Motive Diesel): EMD is a leading manufacturer of diesel-electric locomotives and power assemblies. Their power assemblies are designed to provide maximum power output while minimizing fuel consumption. EMD’s commitment to innovation and technology ensures that their power assemblies deliver exceptional performance and reliability.

- Wabtec Corporation: Wabtec Corporation is a global provider of equipment, systems, and services for the rail industry. They offer a comprehensive range of power assemblies for locomotive engines, including both diesel and electric options. Wabtec’s power assemblies are designed to meet the specific needs of each customer, ensuring optimal performance and efficiency.

In conclusion, when it comes to choosing power assemblies for locomotive engines, it is important to consider reputable manufacturers that have a proven track record in the industry. General Electric, Cummins, EMD, and Wabtec Corporation are among the top manufacturers known for their high-quality power assemblies that meet the demanding requirements of the rail industry.

Conclusion

In conclusion, when it comes to power assemblies for locomotive engines, there are several key points to keep in mind. By understanding the importance of power assemblies and considering factors such as durability, performance, and cost-effectiveness, you can make an informed decision for your locomotive engine needs.

Summary of key points and recommendations for choosing power assemblies for locomotive engines

- Durability: Power assemblies should be made from high-quality materials that can withstand the demanding conditions of locomotive engines. Look for assemblies that are built to last and can handle the wear and tear of heavy-duty use.

- Performance: Consider the power output and efficiency of the assemblies. Look for options that can provide the necessary power and performance to meet the demands of your locomotive engine.

- Cost-effectiveness: While it’s important to invest in high-quality power assemblies, it’s also essential to consider the cost. Look for options that offer a balance between quality and affordability.

- Compatibility: Ensure that the power assemblies you choose are compatible with your specific locomotive engine model. Check the specifications and consult with experts if needed to ensure a proper fit.

- Maintenance and support: Consider the availability of maintenance services and support for the power assemblies. Look for suppliers or manufacturers that offer reliable customer support and have a reputation for providing quality products.

By considering these key points and recommendations, you can choose power assemblies that will enhance the performance and longevity of your locomotive engine. Remember to prioritize durability, performance, cost-effectiveness, compatibility, and reliable support when making your decision.

Read 5 Key Tips for ALCO Diesel Engine Maintenance.