You’ll notice five key signs when your EMD locomotive’s alternator diodes fail: voltage spikes reaching 20V with excessive AC ripple contaminating sensor signals, grinding or whining noises from the alternator assembly with thermal hotspots, transmission systems entering limp mode due to corrupted control circuits, unbalanced rectification causing voltage drops during acceleration cycles, and erratic auxiliary equipment operation with dashboard warning lights. These electrical signatures create cascading failures throughout your locomotive’s systems, and understanding each symptom’s root cause will help you diagnose problems before they escalate into costly repairs.

Key Takeaways

- Voltage spikes exceeding 20V and unstable alternator output with excessive AC ripple contamination in sensor waveforms

- Grinding, whining, or growling noises from alternator assembly with increased vibration and thermal hotspots around housing

- Transmission entering limp mode and traction motor controllers receiving corrupted signals affecting locomotive responsiveness

- Unbalanced rectification causing voltage drops during acceleration and reduced efficiency under heavy electrical loads

- Dashboard warning lights for charging system faults with erratic auxiliary equipment operation and fluctuating gauge readings

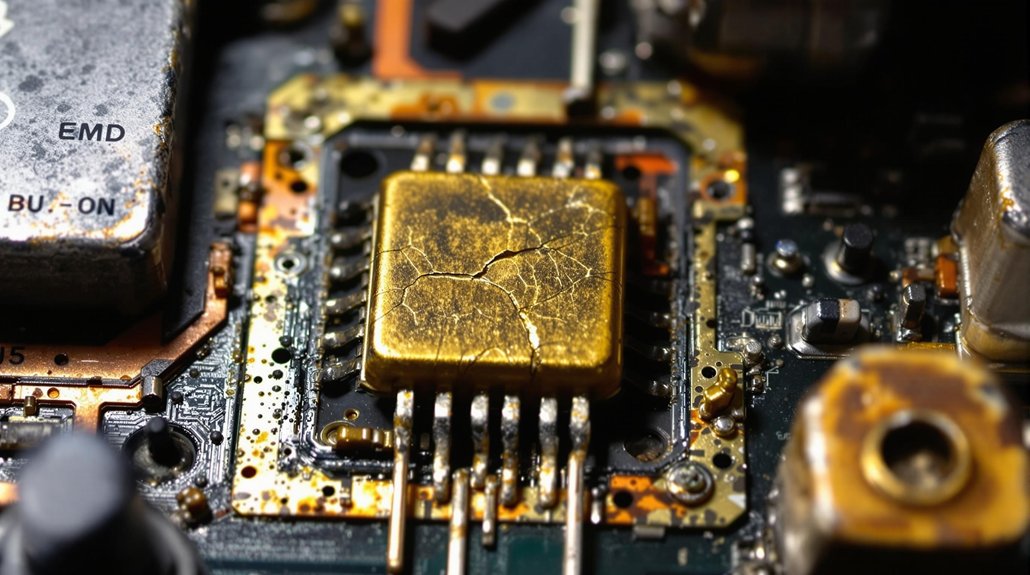

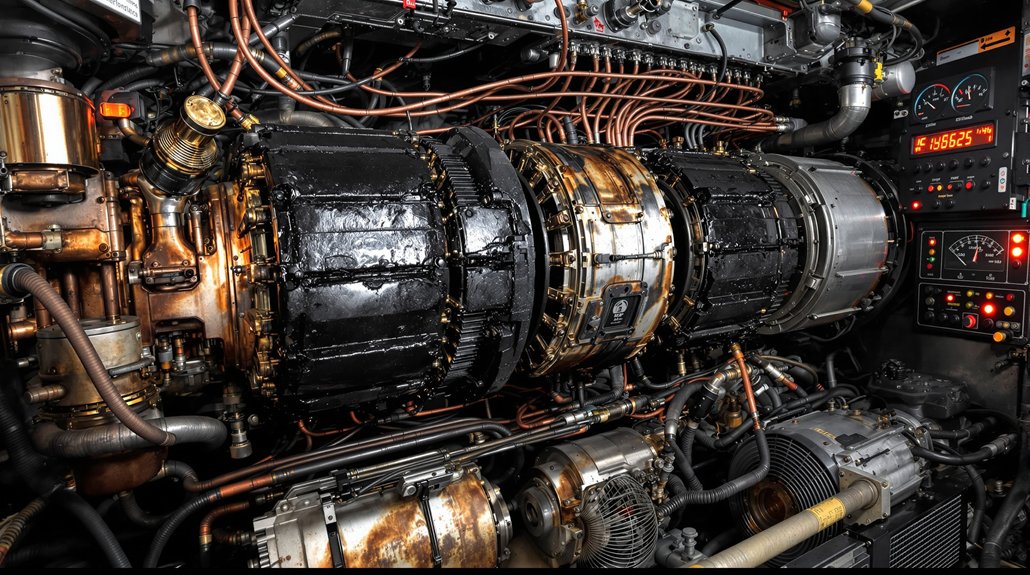

Electrical System Voltage and Current Irregularities

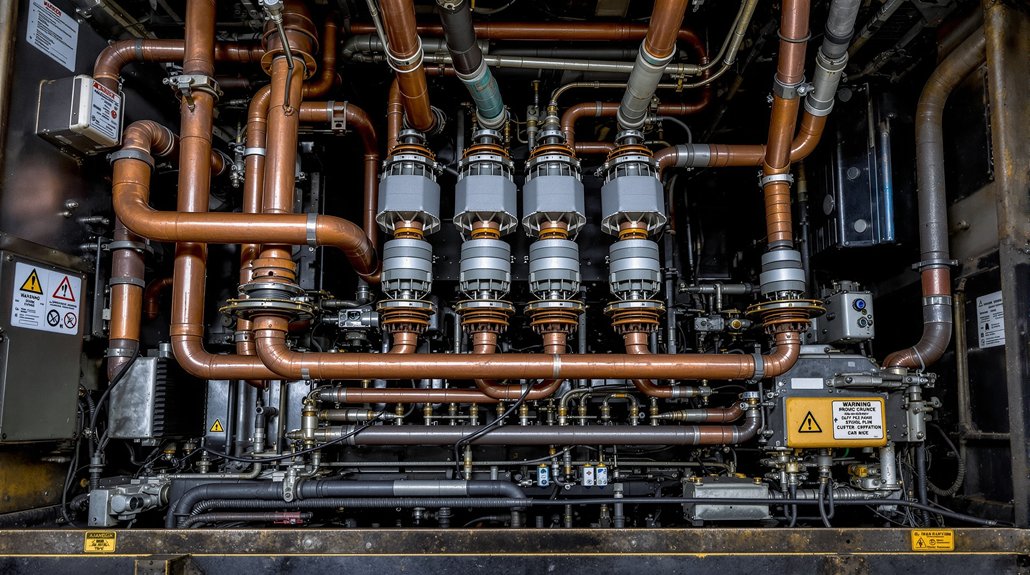

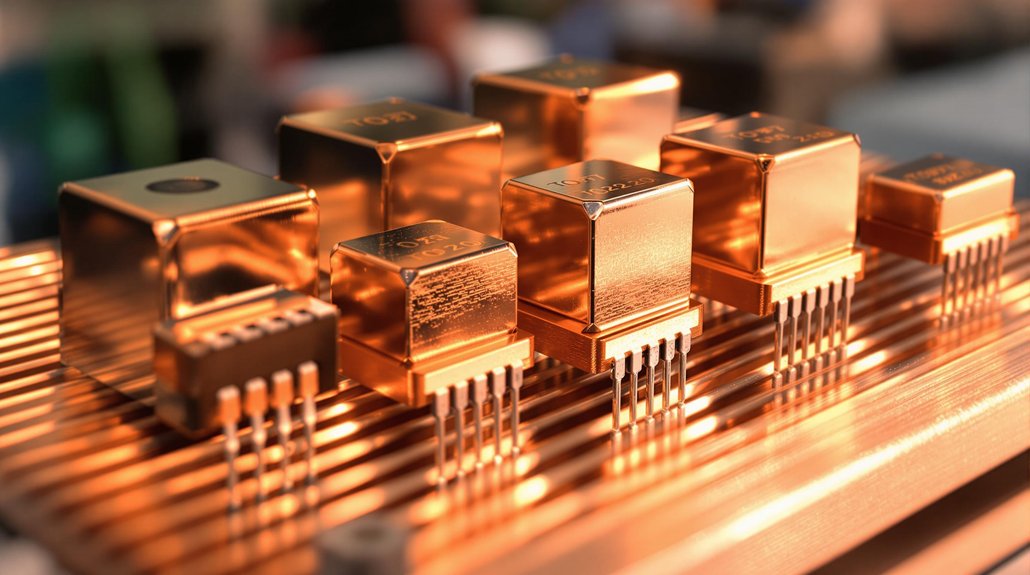

When EMD locomotive alternator diodes begin failing, you’ll notice immediate voltage and current irregularities that compromise your electrical system’s stability. You’ll observe voltage spikes reaching 20V when diodes fail in the bridge configuration, creating dangerous fluctuations that damage sensitive components. The alternator’s output becomes unstable without properly functioning avalanche diodes, preventing consistent AC to DC conversion.

Failed diodes allow excessive AC ripple contamination in your DC circuits, appearing in sensor voltage waveforms and creating interference throughout the electrical system. You’ll detect uneven current distribution across the system when one or more diodes fail, causing amperage output to vary unpredictably with engine speed.

Check for loose connections or damaged wiring that contribute to voltage irregularities. Forward voltage drop increases in degraded diodes, reducing current flow efficiency. Your electrical energy conversion efficiency drops markedly, making proper diode bridge operation critical for maintaining stable locomotive performance. Professional diagnosis using specialized diagnostic tools can accurately identify which specific diodes have failed in the alternator assembly.

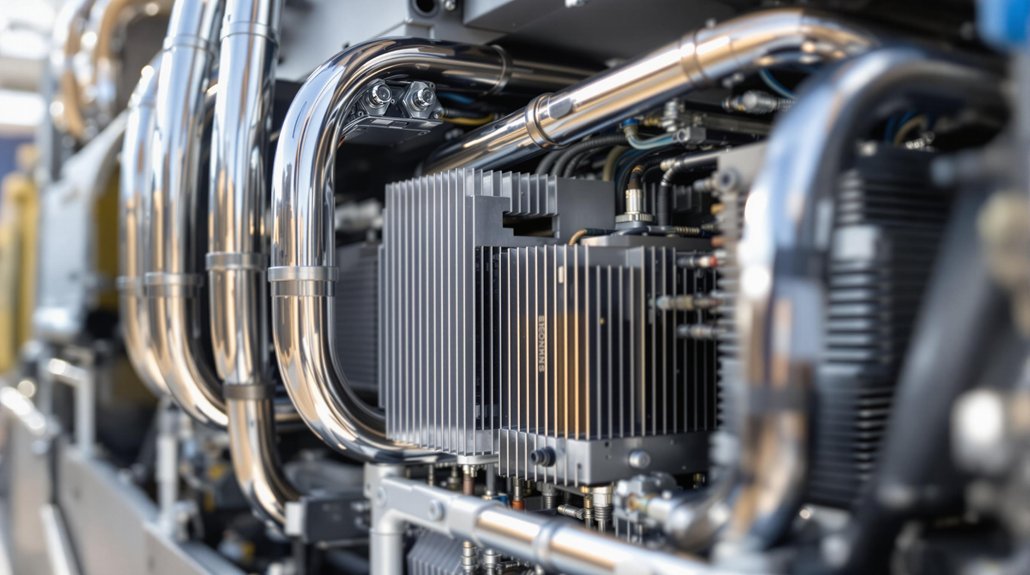

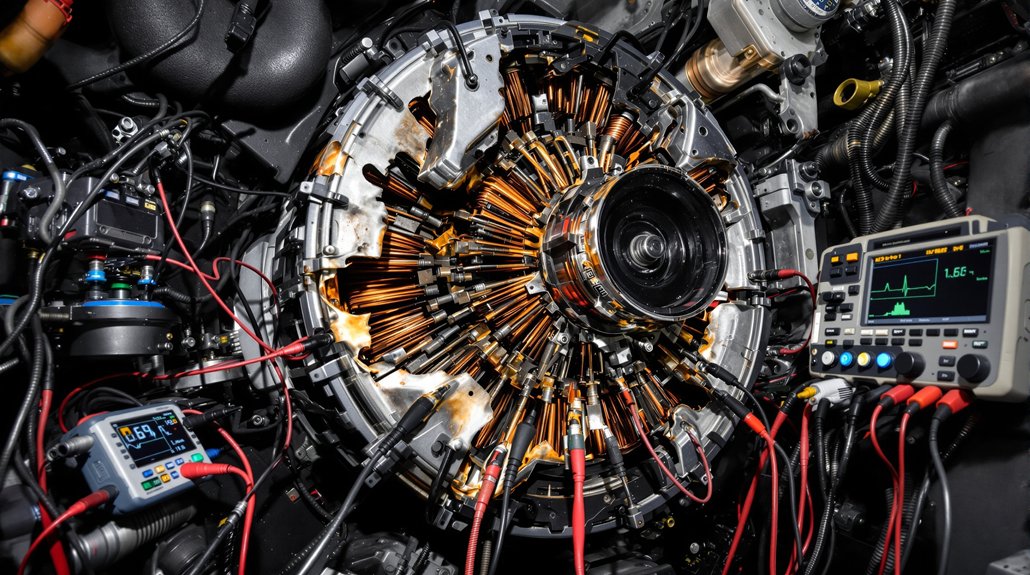

Unusual Noises and Overheating From the Alternator Assembly

Failed alternator diodes kick off a cascade of mechanical and thermal problems that you’ll hear and feel long before complete system failure occurs. You’ll notice grinding and high-pitched whining noises from the alternator assembly as internal components wear under electrical stress. Growling sounds persist when diodes malfunction, creating system imbalances that intensify under load conditions.

Overheating becomes your primary thermal concern as failed diodes force excessive current flow through remaining components. You’ll detect thermal hotspots around the alternator housing when diodes can’t properly convert AC to DC. Bearing failure compounds these issues, generating distinctive noise patterns while alternator vibration increases due to unbalanced electrical loads.

Multiple shorted diodes create more severe conditions than single failures. You’ll hear different sound characteristics as remaining diodes become overloaded. Monitor your cooling system closely—proper ventilation becomes critical when diode failures reduce efficiency and spike heat production throughout the alternator assembly. Failed diodes also produce electrical ripple that can interfere with sensitive electronic sensors throughout the locomotive’s control systems.

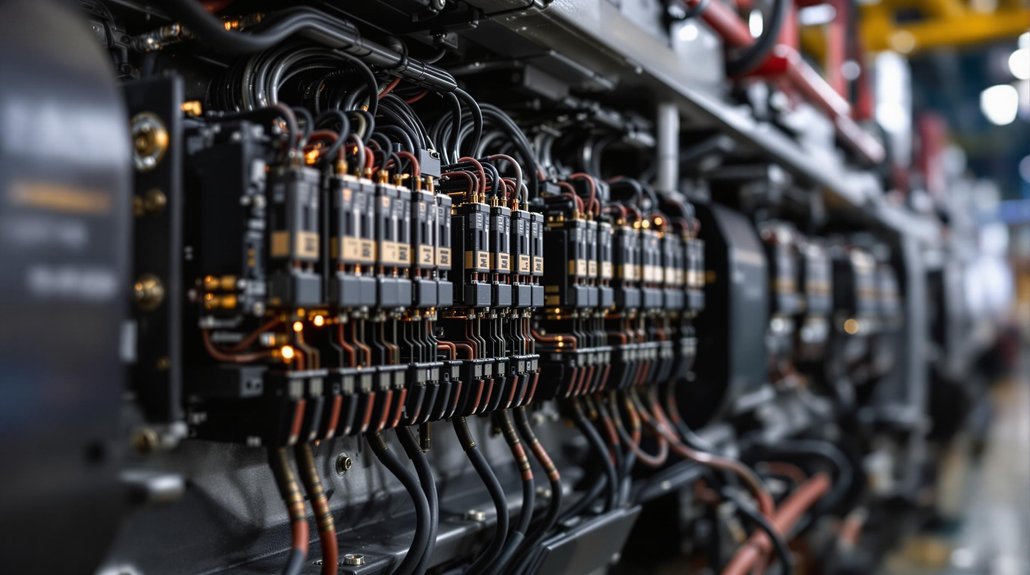

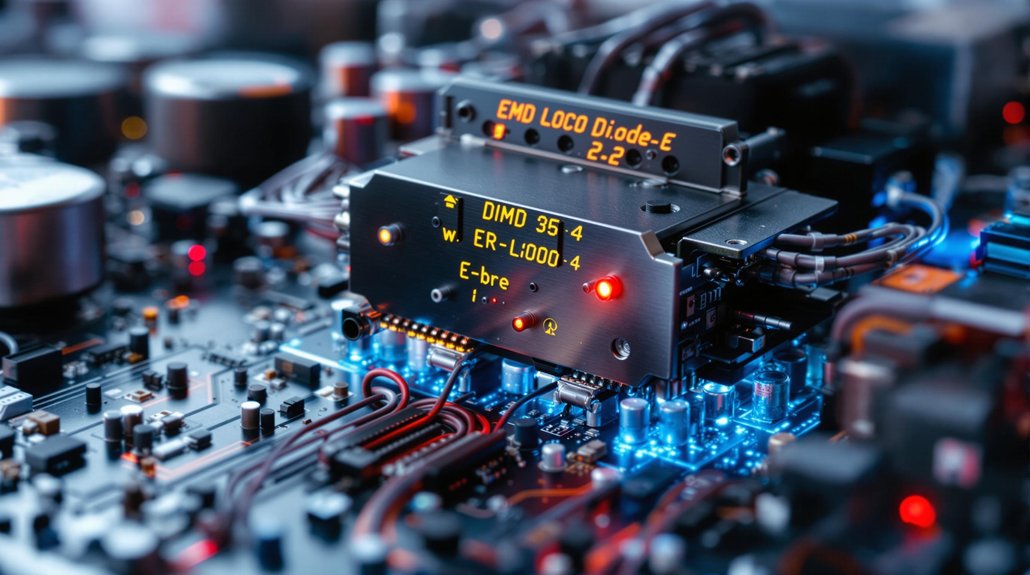

Control System Malfunctions and Transmission Problems

Control system electronics become vulnerable targets once alternator diode failures introduce AC ripple into your locomotive’s electrical network. You’ll notice transmission systems entering gearbox limp mode when electrical interference corrupts control circuits. Speed sensors generate false readings due to AC ripple, creating sensor corruption that affects positioning data and wheel slip detection accuracy.

Your electronic control units face immediate risk from shorted diodes that reflect high voltage ripple throughout electrical systems. Traction motor controllers receive corrupted command signals, making acceleration and deceleration responses unreliable. Dynamic braking systems malfunction when diode failures disrupt regenerative power conversion circuits.

Digital communication networks experience data corruption from electrical interference. CAN bus systems become unreliable, and diagnostic communications fail when AC ripple affects low-voltage circuits. Power management systems generate false alarms due to voltage irregularities, while electronic governors malfunction from voltage fluctuations in sensor power supplies. The voltage regulator struggles to maintain stable output voltage within the desired range when diode failures compromise the rectification process.

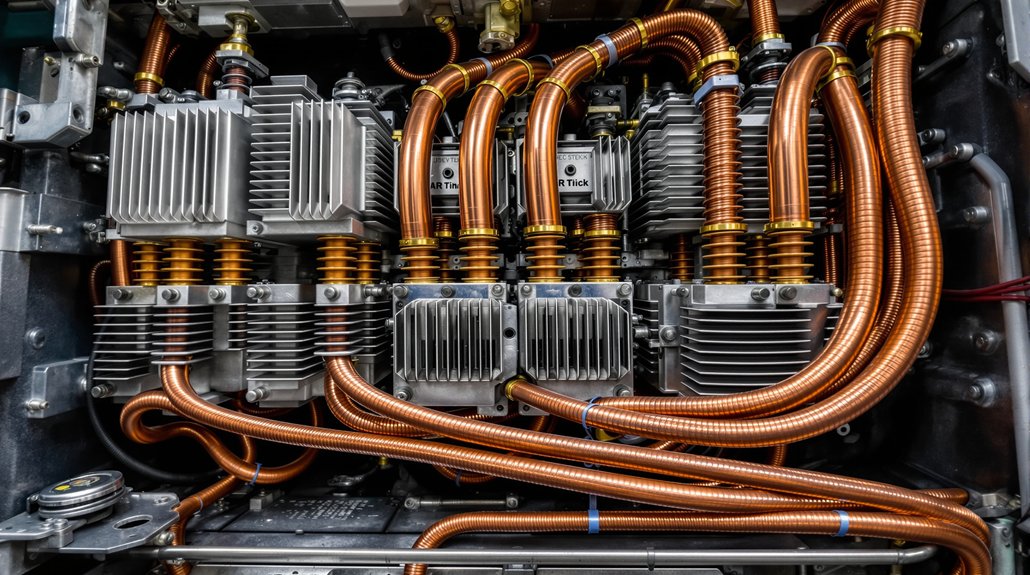

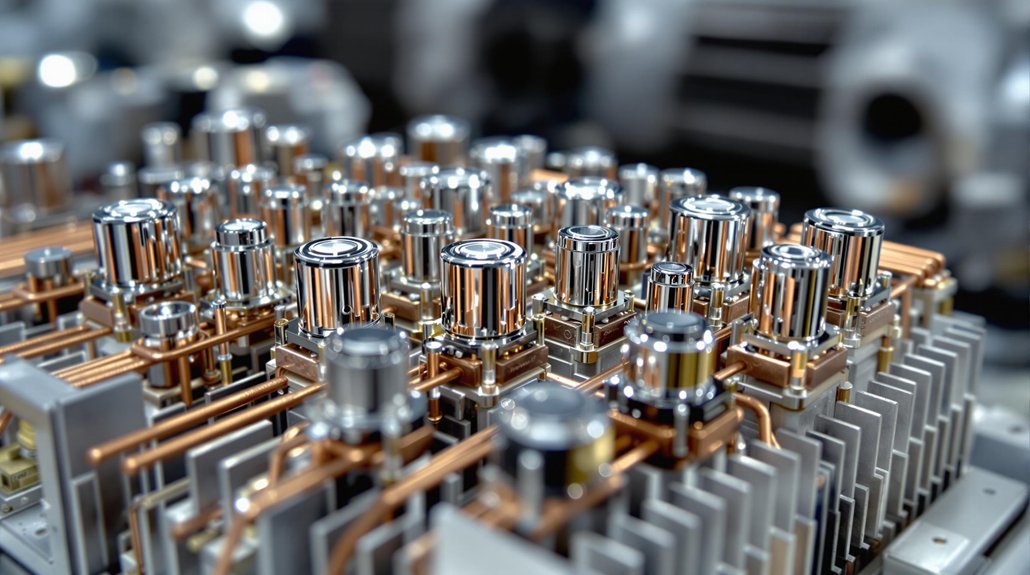

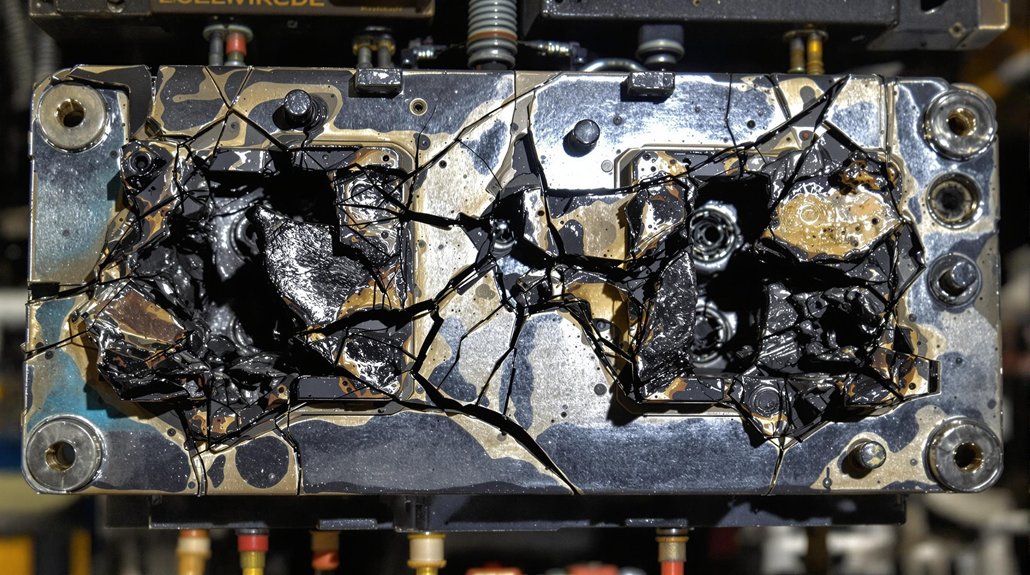

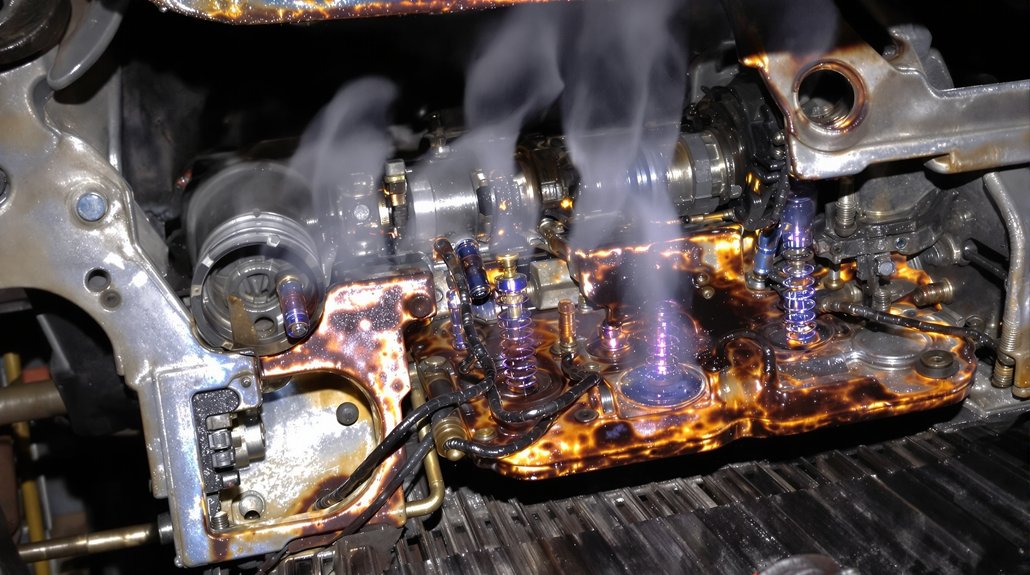

Generator Performance Degradation and Voltage Regulation Failures

As alternator diodes deteriorate, your locomotive’s generator loses its ability to maintain stable DC voltage output across varying load conditions. Failed diodes create unbalanced rectification that compromises voltage regulation during high-demand operations, directly affecting your traction motor performance and overall locomotive efficiency.

You’ll notice these critical performance indicators when diode failures occur:

- Voltage drops during acceleration cycles – Poor load regulation causes insufficient power delivery when you need maximum traction

- Reduced efficiency under heavy loads – Generator output capacity decreases markedly, limiting your locomotive’s hauling capability

- Unstable charging system performance – Battery charging becomes inconsistent, affecting electrical system reliability

Diode bridge failures also compromise ripple mitigation, allowing excessive AC content to contaminate your DC power supply. This creates electromagnetic interference with control systems and sensors. When multiple diodes fail, you’ll experience dramatically reduced efficiency and may need complete alternator replacement to restore proper generator performance. Since diodes are responsible for converting the generator’s AC output into usable DC power, their failure prevents alternator operation entirely in severe cases.

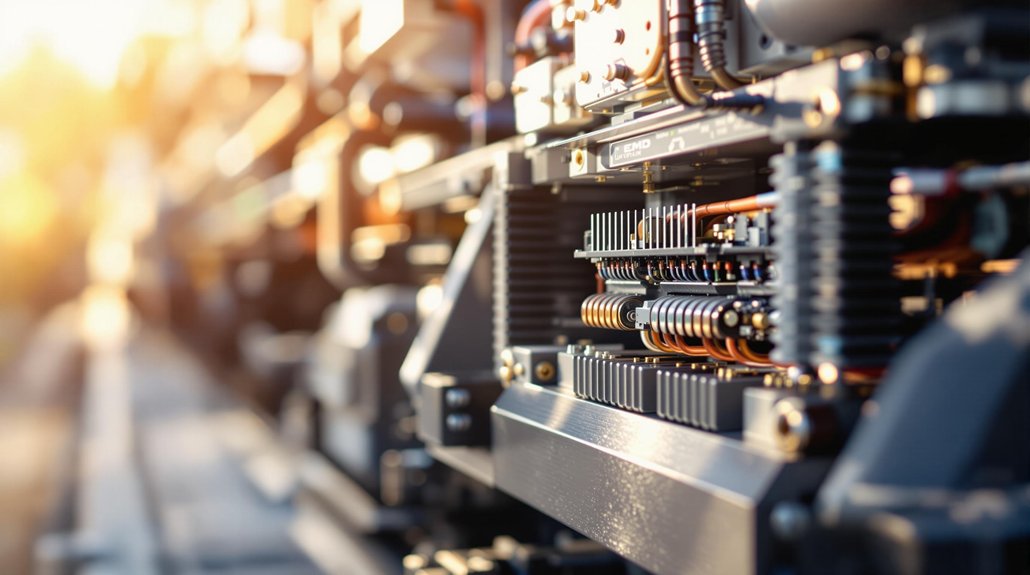

Secondary Equipment Failures and Dashboard Warning Indicators

When alternator diode failures cascade through your EMD locomotive’s electrical system, secondary equipment begins malfunctioning in predictable patterns that you’ll recognize through specific dashboard indicators. You’ll notice auxiliary load systems experiencing erratic operation as voltage regulation becomes unstable. Battery charging circuits struggle to maintain proper levels, triggering low battery warnings on your control panel.

Indicator illumination patterns reveal the progression of diode failure. Your ammeter will show irregular charging rates, while voltage gauges display fluctuating readings that deviate from normal operating parameters. Engine cooling fans may cycle unpredictably due to inconsistent power delivery, and lighting systems often dim or flicker intermittently. A portable oscilloscope can reveal diode faults through distinctive ripple patterns in the electrical output.

Critical dashboard warnings include alternator fault lights, charging system alerts, and battery discharge indicators. You’ll observe that auxiliary systems like air compressors and dynamic brake grids respond sluggishly or fail to engage properly. These secondary failures create a diagnostic trail that helps pinpoint diode degradation before complete alternator failure occurs.

Frequently Asked Questions

How Much Does It Cost to Replace Failed Alternator Diodes in EMD Locomotives?

You’ll face $300-$1,200 in total replacement costs for EMD locomotive alternator diodes, depending on your specific model requirements. Labor costs range substantially based on facility capabilities and testing procedures needed. Complete rectifier assembly replacement includes new bus bars, diodes, and fuses rather than individual components. Consider upgraded components with extended parts warranty coverage, as they’ll reduce future failure rates and provide 12+ year service life versus standard 10-year intervals.

Can You Temporarily Operate a Locomotive With One or Two Failed Diodes?

You can temporarily operate with one failed diode under light loads, but you’ll experience reduced charging capacity and uneven output that stresses remaining components. Two failed diodes create dangerous conditions with excessive excitation current that’ll likely damage your exciter rotor within seconds. You must immediately reduce load and head for repairs – don’t risk progressive failures that’ll cascade through your voltage regulator and electrical system.

What Tools Are Needed to Properly Diagnose Alternator Diode Failures?

You’ll need a digital multimeter with diode test function, AC/DC voltmeter, and continuity tester for basic diagnosis. Add an insulation tester to check diode isolation from ground and housing. A thermal imager identifies overheating diodes under load conditions. Use specialized alternator diode testers with rheostat controls for thorough testing. Include insulated test probes, proper disconnection tools, and cleaning materials for accurate measurements and safe electrical work.

How Long Do EMD Locomotive Alternator Diodes Typically Last Before Failing?

Coincidentally, your EMD locomotive alternator diodes typically last 20,000 to 120,000 hours depending on insulation class and operating conditions. You’ll find Class H systems at 180°C achieve roughly 2.3 years, while Class F systems at 155°C extend service intervals to 13.7 years. Environmental factors like excessive heat, poor ventilation, voltage fluctuations, and contamination markedly reduce lifespan, making regular monitoring essential for peak performance.

Should Locomotive Operators Attempt Field Repairs of Failed Alternator Diodes?

You shouldn’t attempt field repairs of failed alternator diodes. These repairs pose significant safety risks including electrical shock and cascading system damage. Field modifications will void your locomotive’s warranty and violate manufacturer specifications. Diode replacement requires specialized training in high-voltage AC/DC conversion systems, professional diagnostic equipment, and knowledge of excitation circuits. Instead, contact certified EMD technicians who possess proper tools and expertise for safe repairs.