To maximize your EMD locomotive diode efficiency, implement real-time voltage and current monitoring to maintain tight control and detect anomalies early. Enhance regenerative braking to reduce thermal stress and manage power flow effectively. Use modular power electronics for fault isolation and apply advanced cooling systems like liquid-cooled modules to dissipate heat efficiently. Integrate feedback loops in power circuits and employ predictive maintenance to extend diode lifespan. Also, train operators on efficient control strategies to enhance overall system reliability. Further insights reveal how these techniques interconnect for peak performance.

Key Takeaways

- Implement real-time voltage and current monitoring to maintain diode operation within safe thresholds and prevent overload.

- Use forced-air or liquid cooling systems combined with thermal sensors to effectively dissipate heat from diode modules.

- Integrate adaptive feedback loops to regulate output voltage dynamically, optimizing diode efficiency under varying load conditions.

- Employ surge protection clamps and circuit breakers to isolate faults quickly and protect diode junctions from transient spikes.

- Schedule predictive maintenance using AI-driven anomaly detection to identify early signs of diode degradation and prevent failures.

Implement Real-Time Voltage and Current Monitoring

When you implement real-time voltage and current monitoring, you gain precise control over your EMD locomotive’s diode efficiency by continuously tracking electrical parameters within tight ±1V thresholds. Utilizing IGBT-based systems, you regulate voltage across the 1,500–25,000V range with high accuracy. Real time analytics platforms, such as Progress Rail’s LIG, provide centralized monitoring of voltage, current, and fault data, enabling immediate detection of deviations beyond preset thresholds. You can configure remote portals to display live readings and adjust sensor thresholds dynamically via over-the-air updates, guaranteeing responsiveness to operating conditions.

Incorporating current transducer arrays enhances fault detection by monitoring traction motor loading, while automated protective responses prevent damage under overload scenarios. Prioritizing Ethernet and serial protocols ensures high-speed data transmission critical for real-time feedback loops. Effective thermal management is essential to maintain component longevity and prevent overheating during high-voltage operations. By standardizing voltage thresholds and integrating continuous data capture, you optimize diode performance, maintain system integrity, and reduce thermal stress, all while enabling proactive maintenance decisions grounded in precise electrical parameter control.

Optimize Regenerative Braking to Reduce Thermal Stress

To optimize regenerative braking and reduce thermal stress, you must enhance energy capture through advanced storage and efficient diode components. Managing heat dissipation is critical, requiring precise thermal controls and improved cooling systems to maintain diode integrity. Finally, balancing power output across braking phases prevents localized overheating and maximizes overall system efficiency.

Enhance Energy Capture

Although regenerative braking offers substantial energy recovery, optimizing its efficiency is essential to reducing thermal stress on locomotive components. You can enhance energy capture by integrating advanced energy management systems (EMS) that maximize kinetic energy conversion during deceleration, targeting efficiency metrics close to 99.8%. Prioritize energy storage solutions capable of rapidly absorbing and redistributing recovered power to prevent bottlenecks and minimize loss.

Employ real-time monitoring to adjust braking intensity based on speed and gradient factors, ensuring maximum energy retention without overloading the system. By aligning regenerative outputs with grid demand and storage capacity, you reduce reliance on resistive dissipation, directly lowering thermal stress. This precise control improves overall energy utilization, extends component lifespan, and supports sustainable operation while maintaining peak diode efficiency in EMD locomotives. Additionally, selecting Lithium Titanium Oxide (LTO) batteries for onboard energy storage has been shown to provide significant net present value benefits while offering reliable and efficient energy recovery in diesel-electric freight trains.

Manage Heat Dissipation

Maximizing energy capture through advanced EMS and real-time control naturally demands effective heat dissipation strategies to protect diode integrity during regenerative braking. You must monitor diode temperatures with high-frequency thermal sensors and use threshold alerts to reduce braking torque when heat transfer risks exceed safe limits. Employ forced-air or liquid cooling systems combined with modular heat sinks made of high thermal conductivity materials to disperse heat efficiently.

Integrate thermal insulation selectively to shield sensitive components without impeding necessary heat flow. Optimize regenerative braking parameters via dynamic resistance tuning and predictive algorithms to balance energy recovery and thermal stress. Automated thermal imaging and logging help identify hotspots and schedule maintenance before damage occurs. By controlling heat transfer and managing thermal insulation, you reduce thermal stress and extend diode lifespan. Additionally, implementing advanced sensors for real-time tracking ensures continuous temperature monitoring to maintain ideal operating ranges and prevent energy recovery losses.

Balance Power Output

When you balance power output during regenerative braking, you directly reduce thermal stress on EMD locomotive diodes and associated components. To achieve this, optimize the power factor by phase-aligning regenerative current with traction circuit demands, minimizing energy harmonics that exacerbate thermal loading. Implement advanced sensors and real-time algorithms to adjust braking force dynamically, limiting variable current based on speed and load. Incorporate supercapacitors for immediate energy storage, reducing surge impacts and smoothing power delivery.

This approach is similar to how modern hybrid and electric vehicles utilize regenerative braking to extend battery range by efficiently managing energy flow and storage regenerative braking. Coordinate regenerative efforts with substations or neighboring trains to redistribute energy efficiently, preventing excessive diode heating. Additionally, regulate voltage through bidirectional inverters to maintain stable power flow. By integrating these strategies, you enhance diode longevity, improve energy recovery rates, and maintain system stability under varying operational conditions.

Utilize Modular Power Electronics for Fault Isolation

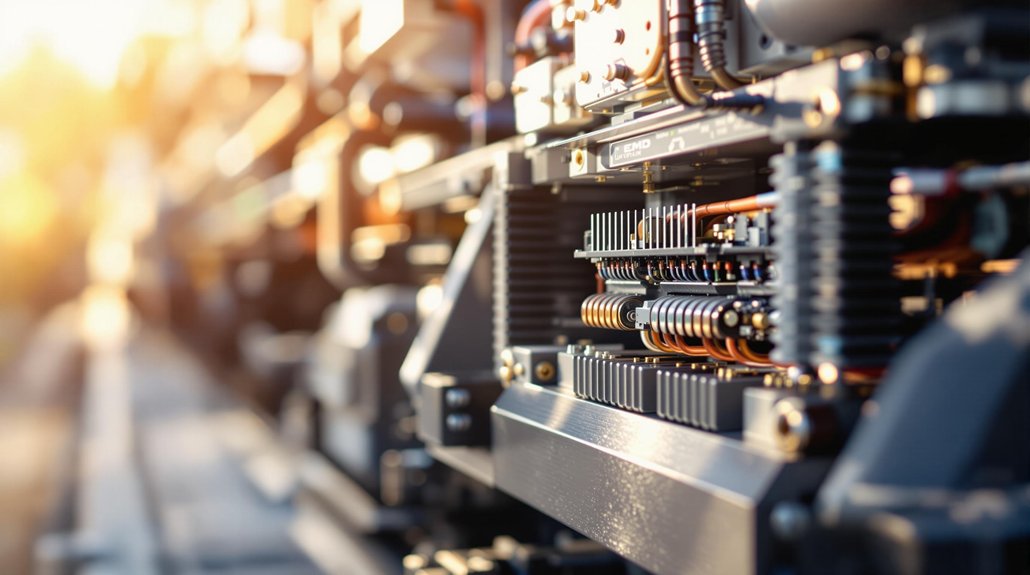

Because fault isolation is critical to maintaining locomotive power system reliability, modular power electronics play a pivotal role in containing failures without cascading effects. By employing modular designs with isolated thermal baseplates, you prevent thermal cross-talk between rectifiers and diodes, enhancing thermal management and component isolation. This approach considerably boosts fault tolerance by localizing failures within discrete modules, facilitating rapid isolation and minimizing downtime.

Maintenance efficiency improves through standardized drop-in replacements and calibration-free modular upgrades, enabling swift service without extensive recalibration. Enclosed high-voltage packages reinforce electrical safety by preventing arcing and interference. Together, these practices guarantee optimized load sharing and electrical protection, empowering you to sustain peak diode efficiency while safeguarding locomotive power electronics against fault propagation and thermal stress.

Apply Advanced Cooling Systems for Diode Protection

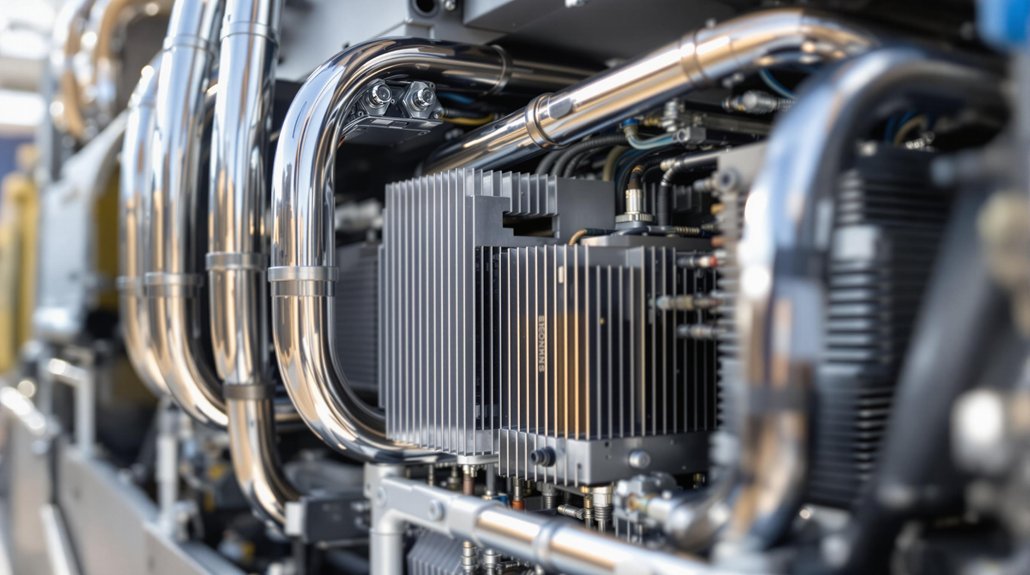

Although diode efficiency depends heavily on electrical design, advanced cooling systems play an equally critical role in protecting these components from thermal stress and premature failure. You must leverage cooling innovations that optimize thermal efficiency, ensuring diode longevity and consistent performance. Liquid-cooled diode modules directly transfer heat to coolant, preventing hotspots, while multi-stage radiator sections enhance heat exchange via parallel flow paths. Additionally, phase-change materials stabilize diode temperatures during transient loads, smoothing thermal fluctuations that otherwise degrade diode reliability. The cooling system’s centrifugal gear-driven pumps are essential for maintaining steady coolant flow, which is vital to effective heat removal from diode modules.

Key strategies to apply include:

- Employing centrifugal gear-driven pumps with pressure-optimized flow paths to deliver uniform coolant distribution around diode modules.

- Integrating high-conductivity heat sinks aligned with electric fan coordination for precise airflow targeting diode heat dissipation.

- Implementing predictive maintenance using laser thermography and real-time data logging to detect thermal anomalies early and avoid cooling system failures.

Integrate Feedback Loops in Power Conversion Circuits

You need to implement feedback loops that dynamically adjust output voltage in real time to respond to varying load conditions. This precise load-responsive control not only stabilizes power delivery but also enhances diode protection by preventing voltage spikes. By integrating such adaptive mechanisms, you optimize efficiency and safeguard critical components within the EMD locomotive power system. High output current converters often improve efficiency by replacing diodes with FETs in synchronous rectification, reducing losses in the power stage switching efficiency.

Dynamic Output Adjustment

When integrating feedback loops in power conversion circuits, dynamically adjusting the output voltage enhances both efficiency and adaptability. You can leverage dynamic feedback techniques like DAC injection or PWM-controlled voltage shifting to finely regulate voltage levels in real time. This dynamic output adjustment guarantees precise voltage regulation, minimizing power loss and optimizing diode performance under varying loads.

Key implementation considerations include:

- Selecting precision DACs and optimizing resistor values (R_ADJ) to maintain accuracy and minimize noise. The LTC7106 DAC, for example, offers excellent current output accuracy over a wide temperature range, ensuring stable voltage adjustments.

- Managing voltage slew rates with stepwise voltage increments to prevent triggering protection circuits.

- Incorporating low-pass RC filters to suppress switching noise in PWM-generated adjustment signals.

Load-Responsive Voltage Control

Since load conditions can change rapidly, integrating load-responsive voltage control through feedback loops is crucial for maintaining ideal diode efficiency in EMD locomotives. You must implement precise control strategies that monitor load voltage in real-time, adjusting outputs to minimize transient deviations and optimize power delivery. Distributed power architectures with point-of-load converters improve transient response by localizing voltage regulation. Incorporate differential sensing and carefully matched components to guarantee feedback accuracy and stability.

| Parameter | Control Strategy | Impact on Efficiency |

|---|---|---|

| Load Voltage Variation | Real-time feedback compensation | Minimizes voltage overshoot |

| Transient Response | Active damping & PoL converters | Stabilizes diode operation |

| Component Matching | 0.1% tolerance resistors | Guarantees precise feedback |

| Switching Frequency | Adaptive control algorithms | Reduces switching losses |

Diode Protection Mechanisms

Effective diode protection mechanisms hinge on integrating real-time feedback loops within power conversion circuits to safeguard against electrical and thermal stresses. You must monitor voltage and current continuously to detect conditions that precipitate diode failure, guaranteeing immediate intervention. Surge protection plays a critical role by clamping transient voltage spikes before they damage diode junctions. Combining automated fault responses with thermal management optimizes diode reliability and longevity.

Key strategies include:

- Voltage/Current Surveillance: Enables early detection of anomalies triggering protective actions.

- Circuit Breaker Activation: Rapidly isolates faulty sections to prevent cascading failures.

- Thermal Monitoring and Cut-offs: Maintains diode operation within safe temperature thresholds.

Implementing these feedback-integrated protections guarantees robust diode performance under dynamic locomotive power demands.

Deploy Predictive Maintenance Algorithms for Diode Health

Predictive maintenance algorithms harness real-time sensor data and machine learning models to identify early signs of diode degradation in EMD locomotives. By integrating multi-sensor inputs—temperature, vibration, and electrical metrics—you can track diode health with precision. Employ AI-driven anomaly detection to flag deviations in electrical signals or thermal gradients, employing convolutional neural networks and Bayesian reliability models for accurate failure probability forecasts. Time-series forecasting with LSTM layers predicts remaining diode lifespan, enabling timely interventions.

Focus on diode-specific indicators like insulation resistance shifts and partial discharge signals to refine predictive thresholds based on historical failure data. Integrate physics-informed models that account for thermodynamic and electrical principles to enhance prediction reliability. By aligning predictive algorithms with maintenance workflows, you prioritize failure modes by operational impact, optimize spare parts inventory, and reduce unplanned outages. This analytical approach empowers you to proactively maintain diode health, ensuring maximum efficiency and minimizing costly downtime in EMD locomotive operations.

Train Operators on Efficient EMS Utilization and Controls

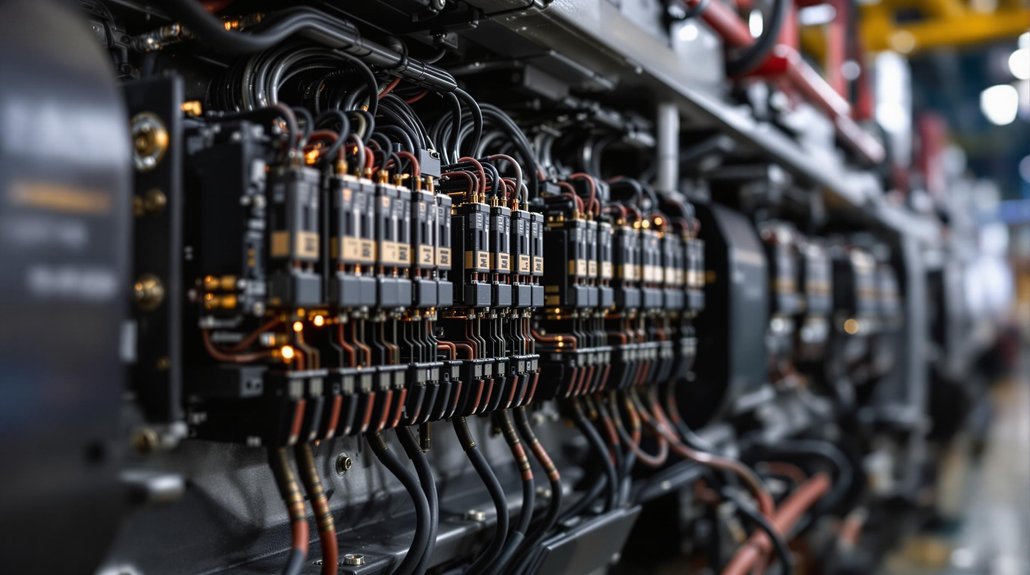

Maintaining diode health through predictive algorithms provides valuable data, but operators must also leverage this insight by mastering the efficient use of the Electrical Management System (EMS) controls. Your active operator engagement is essential for implementing control strategies that optimize diode performance and prevent faults. You should focus on real-time interpretation of monitoring data and swift fault response to maintain system integrity.

Key practices include:

- Utilizing hands-on EMS training to interpret diode health metrics and adjust controls proactively.

- Executing precise load balancing and voltage regulation to stabilize traction motor operations and reduce diode stress.

- Applying fault isolation protocols using integrated protective devices like vacuum circuit breakers to minimize damage during anomalies.

Frequently Asked Questions

How Do Different Diode Types Affect Overall Locomotive Performance?

You’ll find diode characteristics essential in shaping locomotive performance. Fast-recovery diodes enhance switching speed, improving dynamic braking and reducing torque instabilities. Low forward voltage drop diodes minimize energy losses, boosting efficiency. High breakdown voltage and low leakage current guarantee reliability under surges and idle modes. By analyzing performance metrics like recovery time and thermal behavior, you can select diodes that stabilize traction motor currents, optimize power conversion, and maintain system voltage regulation effectively.

What Is the Lifespan of Diodes Under Normal Operating Conditions?

You can expect diode degradation to limit the operational lifespan of diodes to roughly 25,000 to 50,000 hours under normal conditions. Temperature plays a critical role; reducing case temperature by 10°C can statistically double lifespan. Operating diodes at lower current and voltage levels also slows degradation. Maintaining proper thermal management and minimizing stress factors directly extends your diodes’ reliability and guarantees they perform effectively throughout their expected service life.

Can Diode Efficiency Be Improved Through Hardware Upgrades Alone?

You can improve diode efficiency through hardware upgrades alone by focusing on enhanced diode design and thermal management. Upgrading to low forward-drop diodes and integrating advanced gate driver circuits optimizes electrical performance. Meanwhile, improving thermal management—like adding advanced heat sinks, thermal interface materials, and active cooling—reduces junction temperatures and thermal stress. These combined hardware enhancements directly increase efficiency without needing software or operational changes.

How Does Ambient Temperature Influence Diode Failure Rates?

You’ll find that ambient conditions greatly affect diode failure rates by influencing their operating temperature. Higher ambient temperatures increase diode junction temperatures, accelerating failure mechanisms exponentially, as described by the Arrhenius equation. Effective thermal management becomes critical to mitigate this impact; without it, thermal stress and oxidation escalate, reducing diode lifespan. By controlling ambient conditions through cooling and heat dissipation strategies, you can considerably lower failure rates and maintain diode reliability.

Are There Specific Brands of Diodes Recommended for EMD Locomotives?

You should prioritize diode brands that strictly meet EMD specifications to guarantee peak performance and reliability. Progress Rail, as EMD’s official successor, offers certified OEM diodes designed specifically for EMD locomotive systems. Mikura International also provides genuine EMD-compatible components with model-specific expertise. Avoid generic brands; they often fail to match EMD voltage and durability standards. Always verify part numbers and branding to confirm compliance with EMD engineering requirements.