You should monitor locomotive bearing wear because catastrophic failures cost an average of $1.7 million per incident through derailments, emergency response, and cascading network disruptions. Early detection at 10-20% remaining bearing life prevents expensive crankshaft replacements and months of downtime. Modern vibration analysis and wireless sensor networks provide 1-3 months of lead time, enabling scheduled maintenance that reduces unplanned failures by 75%. Discover how condition-based monitoring transforms your fleet’s reliability and operational efficiency.

Key Takeaways

- Catastrophic bearing failures cause immediate operational shutdowns, derailments, and cascading network disruptions costing millions in damages and repairs.

- Early detection through vibration analysis identifies defects at 10-20% remaining bearing life, preventing costly crankshaft and bedplate damage.

- Multi-parameter monitoring provides 1-3 months lead time for scheduled maintenance compared to traditional imminent-failure hotbox alarms.

- Predictive maintenance strategies can prevent up to 80% of unplanned locomotive service interruptions through data-driven bearing replacement protocols.

- Fire and explosion risks emerge when bearing temperatures reach 253°F above ambient, creating environmental liability and safety hazards.

Catastrophic Bearing Failures Lead to Costly Locomotive Downtime

When locomotive bearings fail catastrophically, you’re facing immediate operational shutdowns that cascade into massive financial losses across your entire rail network. Recent derailments like East Palestine demonstrate how bearing failures create devastating consequences—that bearing traveled 26 miles while “on fire,” passing through three hot bearing detectors before causing a $258.3 million incident.

You’ll absorb approximately $31,000 per derailed car, plus $1,572,000 in downstream disruptions per incident. Emergency response costs hit $60,000, with additional operating expenses of $73,000. Your dead trains create bottlenecks that damage customer perception and trigger regulatory penalties.

Recovery operations demand specialized equipment and personnel, straining your spare management systems. Service interruptions reduce schedule reliability and revenue generation capacity. With North Carolina experiencing $2.4 billion in rail incident costs over ten years, thorough crew training and proactive bearing monitoring become essential for protecting your operational continuity and financial stability. Bearing failures can occur in less than 3 minutes, making real-time monitoring systems critical for preventing catastrophic incidents.

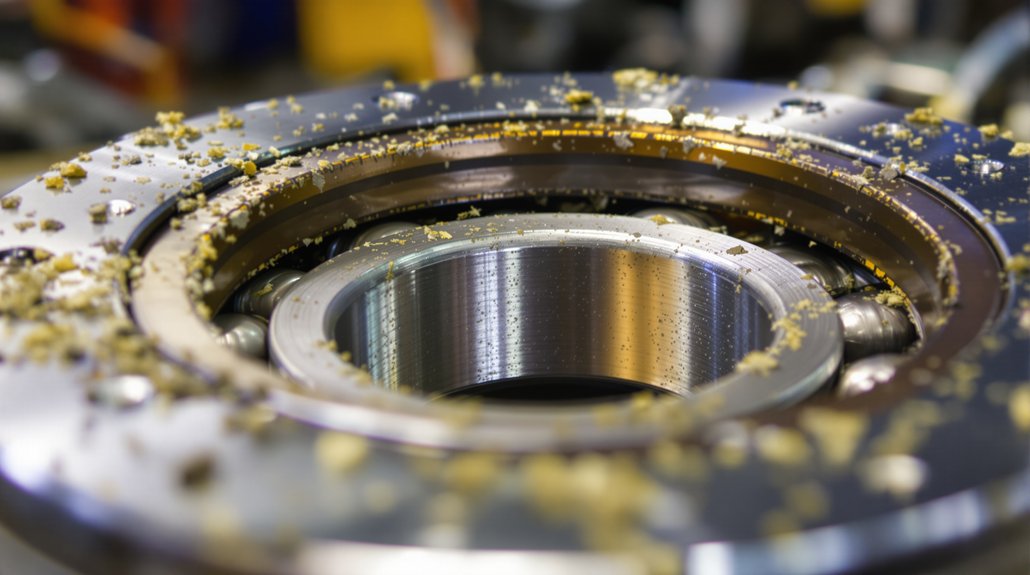

Early Detection Prevents Expensive Crankshaft and Bedplate Damage

When you implement early bearing detection systems, you’ll prevent catastrophic failures that can destroy expensive crankshaft and bedplate components costing hundreds of thousands in repairs. Vibration analysis detecting defects at 10-20% remaining bearing life gives you sufficient lead time to schedule maintenance before secondary damage occurs to these critical engine components. Your proactive monitoring strategy transforms potentially devastating equipment failures into manageable, cost-effective bearing replacements that keep locomotives operational and maintenance budgets under control. Combining multiple sensor types with vibration monitoring improves accuracy and reliability of fault identification across all bearing conditions.

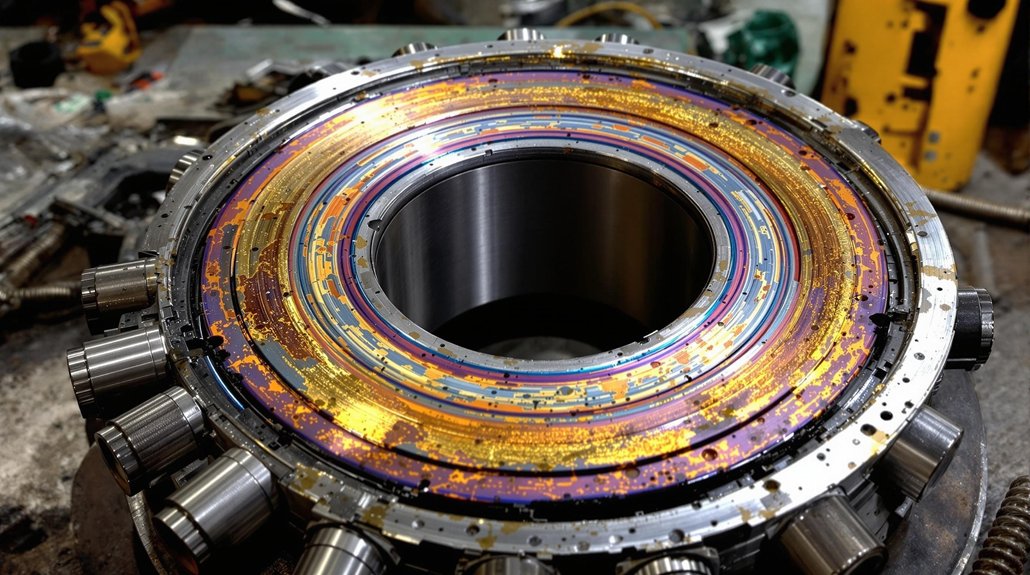

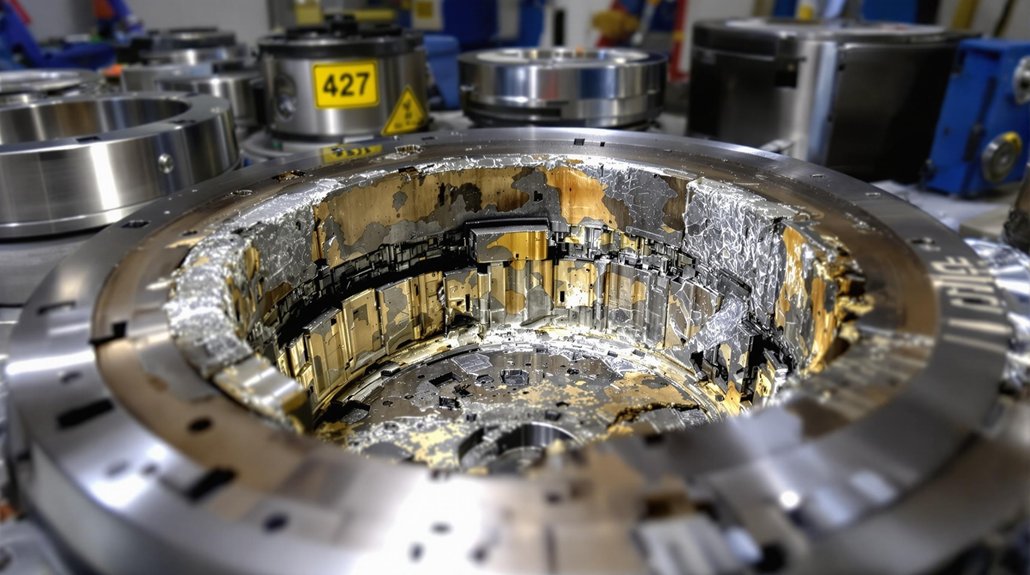

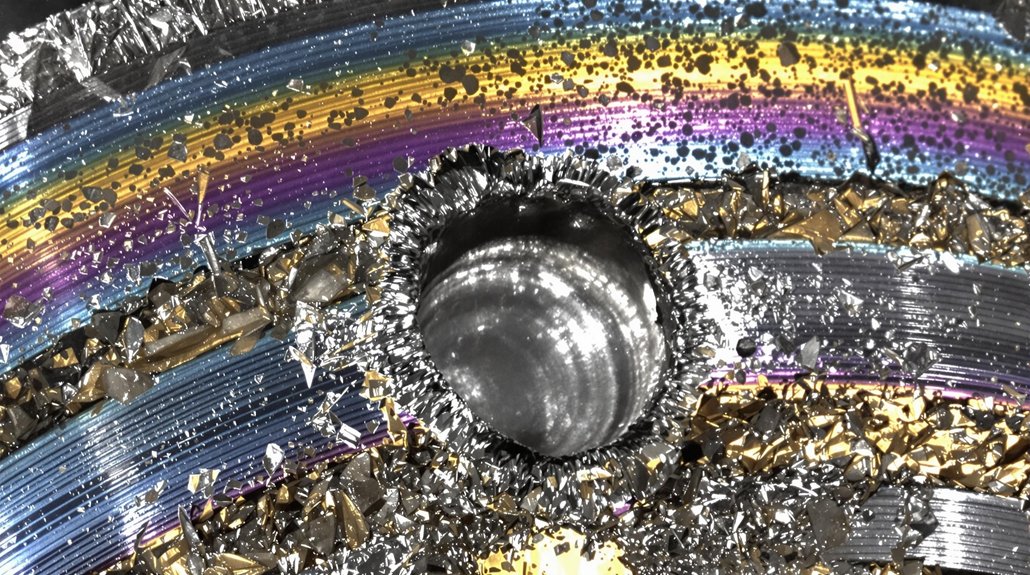

Catastrophic Failure Consequences

Although locomotive bearing failures may seem isolated to wheel assemblies, catastrophic consequences cascade throughout your entire drivetrain system when detection systems fail to provide adequate warning. When bearings disintegrate at operational speeds, you’re facing multi-million dollar crankshaft replacements and extensive bedplate damage that can sideline locomotives for months.

The East Palestine derailment demonstrates how bearing failures create catastrophic chain reactions:

- Fire and explosion risks – Bearing temperatures reaching 253°F above ambient trigger immediate fire hazards requiring emergency response

- Environmental liability exposure – Hazardous material releases create long-term cleanup costs and community health impacts exceeding operational losses

- Complete drivetrain destruction – Heat-related failures propagate through connected systems, destroying crankshafts, bedplates, and transmission components simultaneously

Current detection thresholds provide insufficient warning time for prevention. Advanced detection systems have proven effective, with hotbox detectors contributing to a 59% decline in bearing-related accidents over nearly three decades.

Cost-Effective Prevention Strategies

Beyond traditional hotbox detection systems that trigger alarms only during imminent failure, you can implement multi-parameter monitoring strategies that detect bearing degradation one to three months before catastrophic damage occurs. Temperature-based early warning systems identify bearing defects through statistical analysis of thermal patterns, while vibration analysis using accelerometers detects amplitude changes indicating misalignment or damage. You’ll achieve optimal results by combining oil analysis, current signature monitoring, and acoustic emission testing for comprehensive condition assessment. This multi-parameter approach enables predictive financing by forecasting maintenance costs months ahead, while supporting inventory optimization through accurate spare parts planning. FFT-based algorithms and VRMS calculations provide quantifiable data that prevents expensive crankshaft and bedplate damage through timely intervention.

Wireless Sensor Networks Enable Real-Time Temperature Monitoring

Wireless sensor networks transform locomotive bearing monitoring by delivering real-time temperature data through sophisticated multi-component architectures that eliminate traditional wiring constraints. You’ll benefit from continuous temperature monitoring through wireless detection modules that communicate with gateway data collectors, enabling immediate identification of bearing overheating conditions before catastrophic failures occur.

Key advantages of wireless bearing temperature monitoring:

- Real time telemetry – Temperature data transmits continuously via Zigbee modules and 4G/LTE gateways, providing instant alerts when bearing temperatures exceed safe operating thresholds

- Mesh resilience – Ad hoc wireless sensor networks create redundant communication paths, ensuring data transmission even if individual nodes fail during critical monitoring periods

- Energy efficiency – Power management systems activate monitoring equipment only during train movement, extending battery life while maintaining all-encompassing coverage

Gateway systems store data locally and transmit remotely in near-real-time, associating temperature measurements with GPS positioning for complete fleet monitoring capabilities throughout your entire train consist. The system employs GPRS wireless communication to enable remote monitoring capabilities from centralized control centers.

Vibration Analysis Techniques Identify Bearing Defects Before Failure

While temperature monitoring provides crucial thermal data, vibration analysis delivers the most all-encompassing diagnostic capability for detecting bearing defects before they cause catastrophic locomotive failures. You’ll achieve superior detection using envelope analysis, which stands as the most effective technique for identifying bearing faults across rotating machinery.

High frequency envelope analysis isolates specific bearing defect signatures by targeting Ball Pass Frequency Outer race (BPFO) and Ball Pass Frequency Inner race (BPFI) frequencies. BPFO typically ranges from 3-8 times rotational frequency, while BPFI exceeds BPFO due to load zone effects.

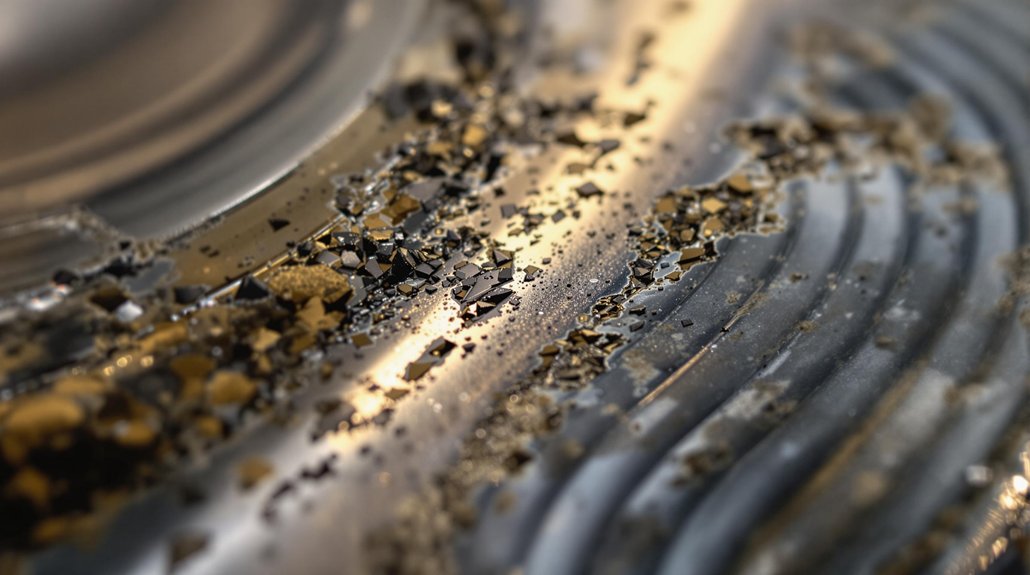

You can enhance your diagnostic accuracy through probability density functions that reveal statistical changes in vibration patterns as bearing condition deteriorates. Root-mean-square measurements provide speed-dependent thresholds to differentiate between healthy and defective bearings, while crest factor analysis identifies impulsive characteristics from surface defects. Since Stage I defects remain undetectable through conventional noise or temperature monitoring, high-frequency vibration techniques become essential for identifying bearing problems in their earliest development phase.

Strategic Maintenance Scheduling Reduces Unplanned Service Interruptions

Through systematic maintenance scheduling, you’ll prevent up to 80% of unplanned locomotive service interruptions by implementing data-driven bearing replacement protocols.

Effective maintenance prioritization transforms reactive repairs into strategic interventions. You’ll establish ideal monitoring intervals using historical failure data, enabling your teams to predict bearing deterioration before catastrophic events occur. This approach requires thorough documentation of oil changes, temperature readings, and inspection results to identify trending issues.

Your strategic framework should integrate three critical components:

- Oil analysis every 60-90 days to detect metal particles and contamination before bearing failure

- Quarterly bearing assessments combined with 3,000-hour inspection cycles for camshaft bearings

- Predictive scheduling algorithms that optimize maintenance timing during planned downtime windows

Resource allocation becomes more efficient when you base decisions on condition predictions rather than arbitrary schedules. You’ll minimize emergency repairs by replacing bearings at 750-hour oil change intervals, maintaining peak locomotive performance while reducing costly service disruptions through well-structured preventive maintenance timing.

Temperature monitoring protocols establish baseline readings that enable early detection of bearing issues before they escalate into temperature spikes requiring immediate shutdown procedures.

On-Board Vs Wayside Monitoring System Options

Locomotive bearing monitoring systems fall into two primary categories: on-board devices that travel with your equipment and wayside installations positioned along track segments. On-board systems integrate thermal, vibration, and acoustic technologies with embedded AI circuits, providing continuous diagnostic data regardless of route changes. These systems sample wheels every minute initially, increasing frequency when parameters indicate potential failure. Sensor miniaturization enables contactless positioning 20-30 centimeters from targets while maintaining 2-year battery life.

Wayside systems use Hot Axle Box Detection with infrared sensors monitoring bearing temperatures as vehicles pass. However, they monitor only during passage, missing intermittent issues between detection points. While wayside installations require fewer initial units, they need permanent infrastructure and regular calibration. Wayside measurements can be compromised by solar reflection, braking sparks, and other nearby heat sources that interfere with accurate temperature readings.

Temporary On-board Monitoring necessitates battery swapping and equipment transfers between rail cars, creating service downtime. Permanent systems eliminate infrastructure maintenance but increase fleet instrumentation costs, making strategic selection critical for your operational requirements.

Safety Systems Automatically Protect Engines During Bearing Wear Events

As bearing wear progresses beyond acceptable thresholds, automated safety systems activate protective protocols that prevent catastrophic engine damage. Your locomotive’s integrated monitoring network employs redundant sensing technology to guarantee reliable fault detection across all critical bearing locations. When temperature sensors detect overheating conditions, automated shutdowns immediately halt engine operation before thermal damage occurs to crankshafts or other major components.

Modern safety systems protect your investment through three critical mechanisms:

- Real-time thermal monitoring triggers protective shutdowns when bearing temperatures exceed safe operating limits

- Multi-parameter detection systems utilize vibration, acoustic, and position sensors for thorough bearing health assessment

- Automated alert protocols deliver immediate notifications to operators and Central Train Control via SMS, email, or direct messaging

These systems eliminate human error in critical failure detection scenarios while providing continuous surveillance without manual intervention. Your engine protection system prevents bearing damage from progressing to catastrophic failure, guaranteeing operational safety and equipment longevity. Advanced bearing technologies require ongoing maintenance activities despite their sophisticated design capabilities.

Fleet-Wide Reliability Improvements Through Condition-Based Maintenance

Modern condition-based maintenance (CBM) strategies consistently deliver fleet-wide reliability improvements by shifting your maintenance approach from reactive repairs to predictive interventions. You’ll achieve optimal resource allocation through predictive prioritization, enabling maintenance teams to address critical bearing wear before failures impact operations.

Asset pooling strategies maximize locomotive availability by redistributing workloads across your fleet based on real-time bearing condition data. This approach extends Mean Time Between Failure (MTBF) intervals while optimizing Expected Useful Life (EUL) calculations.

| CBM Metric | Traditional Approach | CBM Approach | Improvement |

|---|---|---|---|

| Unplanned Failures | 15-20% fleet downtime | 3-5% fleet downtime | 75% reduction |

| Maintenance Costs | $500K annually | $320K annually | 36% savings |

| Asset Utilization | 65% operational | 88% operational | 35% increase |

| Safety Incidents | 12 per year | 2 per year | 83% reduction |

Your maintenance teams can implement data-driven decisions that prevent catastrophic bearing failures while optimizing locomotive deployment across routes. Automated alarm thresholds eliminate the need for specialized user knowledge in interpreting complex bearing condition data, making advanced monitoring accessible to all maintenance personnel.

Frequently Asked Questions

What Is the Typical Service Life of Locomotive Bearings Under Normal Operating Conditions?

You’ll find locomotive bearings typically achieve 20,000 to 27,000 hours of L10 rated service life under standard operating conditions. Your typical lifespan extends to approximately 94,000 miles with proper maintenance protocols. Industry-standard service intervals recommend replacement at 80% of calculated life to prevent catastrophic failures. You’ll maximize bearing longevity through specialized lubrication, temperature monitoring, and contamination control while maintaining strict 92-day oil change schedules for peak performance.

How Much Does Bearing Replacement Cost Compared to Preventive Monitoring System Installation?

You’ll find bearing replacement cost markedly exceeds monitoring system investment. New railway bearings cost approximately $400 per unit, while remanufacturing saves over half that expense. However, you’re still facing substantial replacement costs versus preventive monitoring installation. The monitoring ROI becomes evident when you consider new bearings experienced 27 failure sets compared to 42 for overhaul units, demonstrating how early detection prevents costly emergency replacements and operational disruptions.

Which Bearing Materials Perform Best in Different Climate and Operating Environments?

Ironically, you can’t simply pick one “best” bearing material—your choice depends entirely on environmental demands. Ceramic hybrids excel in high-temperature applications up to 600°C with superior corrosion resistance, while corrosion resistant alloys like enhanced aluminum perform optimally in moderate conditions. You’ll need bronze for heavy-duty locomotive applications requiring excellent heat dissipation, and M50NiL steel for extreme temperature ranges exceeding 400°C with maximum durability.

How Often Should Bearing Condition Data Be Collected for Optimal Monitoring Effectiveness?

You should implement daily sampling during normal operations, then shift to event-driven monitoring when fault indicators emerge. Start with 1-minute intervals during startup, increasing frequency as thermal or acoustic data suggests bearing degradation. Stage II defects require continuous high-frequency monitoring at 5kHz+ ranges. You’ll need real-time analysis when vibration levels exceed RMS velocity limits, ensuring immediate detection before critical failure occurs.

What Backup Systems Activate if the Primary Bearing Monitoring System Fails?

You’re flying blind without proper backup systems, but most modern locomotives deploy redundant sensors and secondary backup diagnostics when primary bearing monitoring fails. You’ll typically find acoustic sensors as secondary monitors, temperature-based backup systems, and manual inspection protocols that activate automatically. These redundant sensors guarantee you’re never completely without bearing condition data, though you’ll need immediate primary system repairs to maintain peak safety margins and prevent catastrophic bearing failures.