TL;DR

- The 52 Inch Cooling Fan is the primary Radiator Cooling Fan, critical for thermal management to prevent engine derating and shutdown in ALCO and EMD Diesel Locomotives.

- Sourcing requires mandatory compliance with the exact drawing specification: DMW Drg. No. EL/PT-0735 ALT-Z, which dictates precise dimensions, high-tensile material, and minimum airflow capacity (e.g., 45,000 CFM).

- The fan assembly requires verification of the correct drive motor (DC Motor or AC Motor) and relies on stable power from the Auxiliary Power Unit (APU) and PM Alternator (2.5 KW or 7.5 KW).

- This fan is integrated with the locomotive’s larger thermal network, indirectly supporting auxiliary systems like the Traction Motor Blower and the Dynamic Braking Grid cooling.

Sourcing locomotive components presents major challenges. Parts managers struggle with precise drawing number verification. Incorrect parts cause immediate fitment failures. This results in costly, unplanned operational downtime. The 52″ Cooling Fan is critical for thermal stability. Mikura International supplies exact replacement parts. We ensure full compliance with original specifications. We eliminate the risk of engine thermal failure.

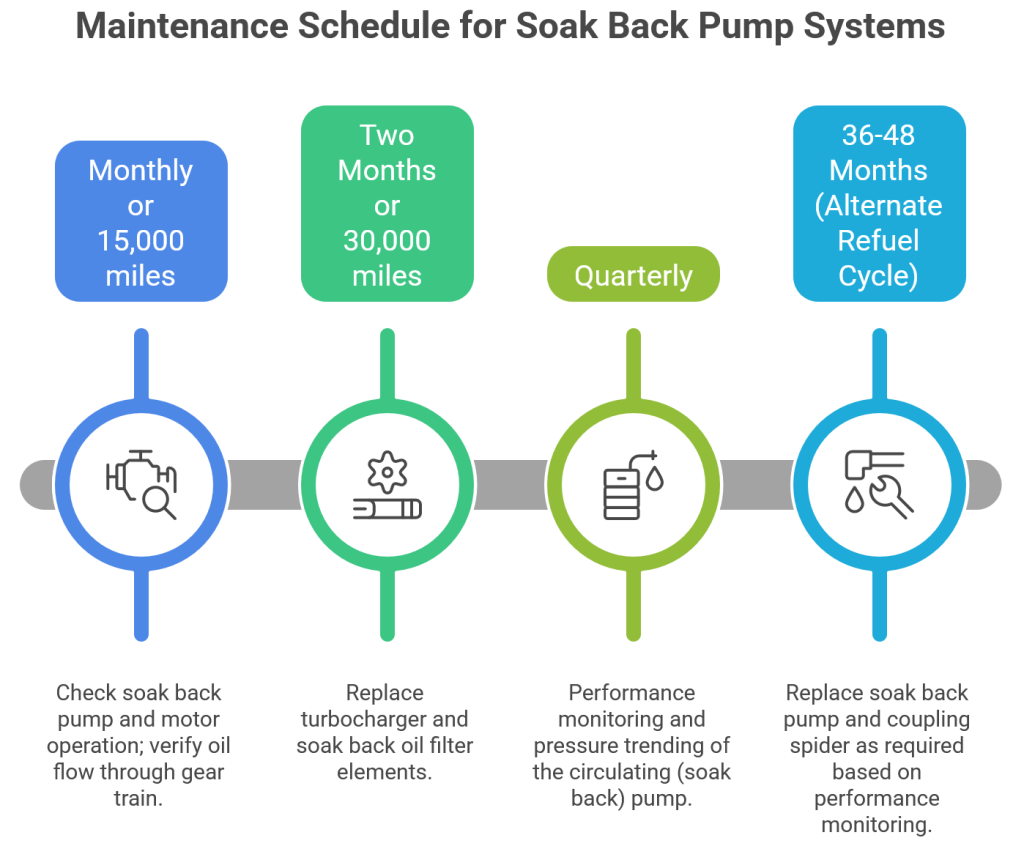

Secure the correct Radiator Cooling Fan component using this verification process. These steps help overcome common sourcing challenges for Diesel Locomotive parts:

- Confirm the required component is the 52″ Cooling Fan.

- Verify the specific drawing number: DMW Drg. No. EL/PT-0735 ALT-Z.

- Identify the correct motor application (DC Motor or AC Motor).

- Ensure the component meets all critical dimensional tolerances.

- Prioritize suppliers offering certified material traceability records.

- Establish a proactive inventory management system for critical parts.

- Review your heat management systems performance quarterly.

- Source all components from specialized Diesel Locomotive providers.

Understanding the DMW 52″ Cooling Fan Specification

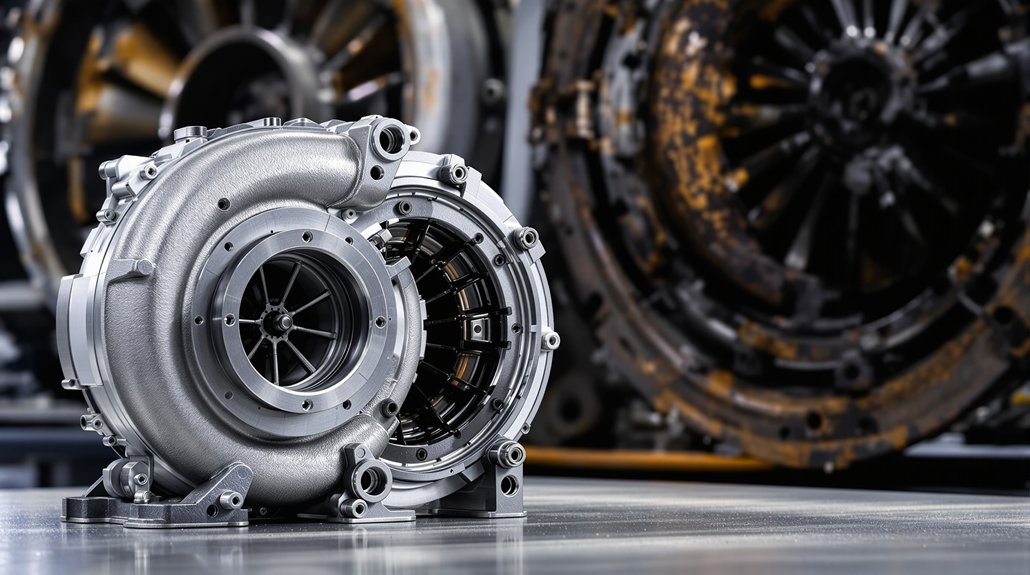

The 52″ Cooling Fan is a critical Diesel Electric Locomotive subsystem. This fan manages core engine heat. Proper function prevents overheating in ALCO and EMD engines. It is often referred to as the Radiator Cooling Fan. Precision is mandatory for operational integrity. This component is distinct from the Traction Motor Blower or Machine Room Blower units.

Failure of the 52″ Cooling Fan compromises the entire system. This leads to reduced performance and engine shutdown. Sourcing managers must verify the exact specifications. Proper thermal management is vital for maintaining motor efficiency and longevity.

Technical Specification: 52″ Cooling Fan (EL/PT-0735 ALT-Z)

Refer to the following table for verified component requirements.

| Specification Detail | Requirement |

|---|---|

| Drawing Number | DMW Drg. No. EL/PT-0735 ALT-Z |

| Fan Diameter | 52 Inches |

| Application Type | Radiator Cooling Fan / Heat Management Systems |

| Compatible Locomotives | ALCO, EMD Diesel Locomotive Classes |

| Motor Variants | DC Motor or AC Motor (Specify kW rating) |

| Related Systems | Dynamic Braking Grid, Oil Cooling Unit Blower |

Critical Role of the Radiator Cooling Fan

The Radiator Cooling Fan ensures the main engine maintains optimal temperature. This is essential for high-horsepower Diesel Locomotive operation. The 52 Inch Cooling Fan moves vast volumes of air. It cools the engine coolant circulating through the radiator core. This prevents thermal stress on cylinder heads and liners.

Contrast this fan with the 48 Inch Cooling Fan or 54 Inch Cooling Fan variants. Dimensional accuracy is non-negotiable for proper fitment. Use the correct DMW drawing number for verification.

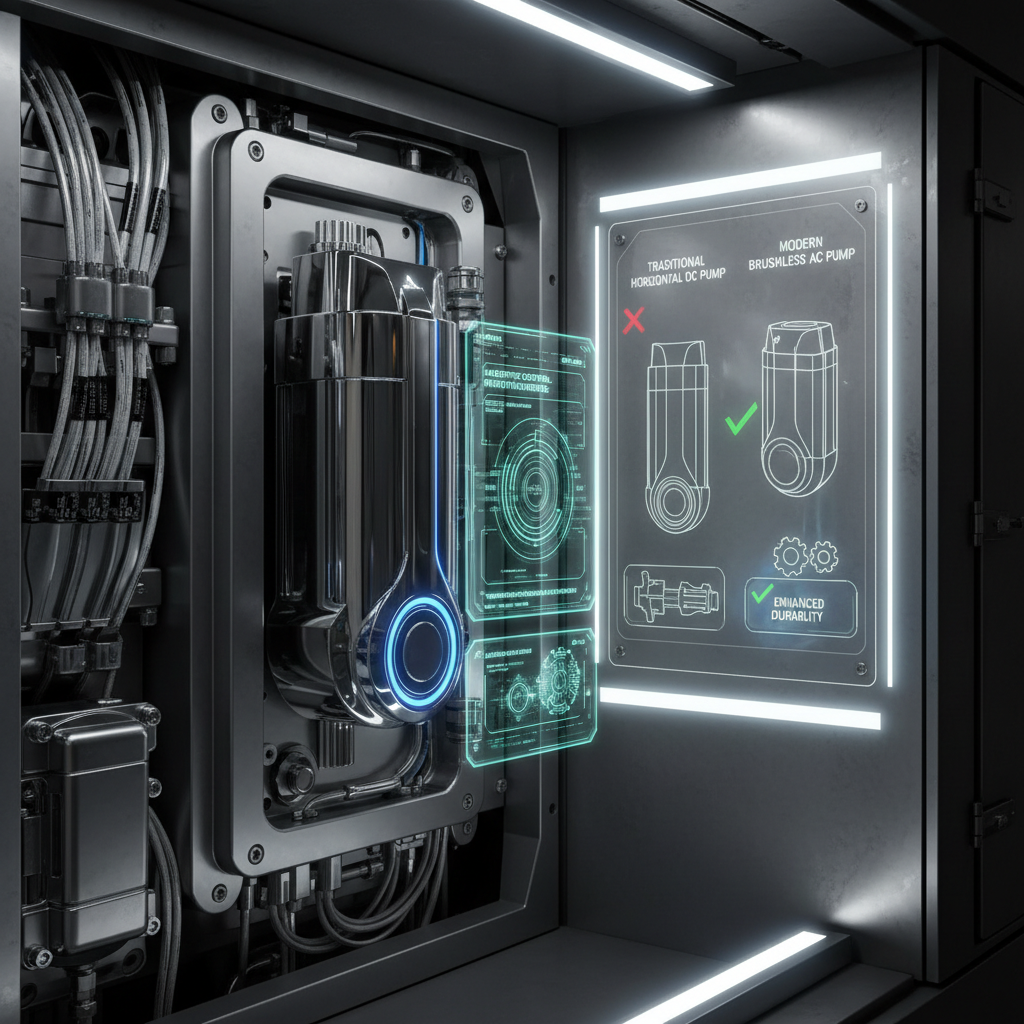

Fan Motor Selection: DC Motor versus AC Motor

The 52″ Cooling Fan requires a powerful drive motor. Locomotives utilize either DC Motor or AC Motor configurations. Selecting the wrong motor type causes immediate system incompatibility. The motor must integrate seamlessly with the locomotive’s Auxiliary Power Unit (APU) supply.

Verify the locomotive’s electrical schematic. Confirm the required voltage and current ratings. Ensure the replacement motor matches the existing setup. This prevents damage to the control system.

Key Motor Specifications

- Determine if the fan uses a DC Motor or AC Motor.

- Verify the required horsepower or kilowatt (kW) rating.

- Ensure mounting flanges match the existing installation.

- Check compatibility with the APU Alternator output.

Accurate component selection minimizes installation time. It maximizes the service life of the cooling system.

Related Innovation

Understanding the 52 Inch Cooling Fan Assembly

The 52 Inch Cooling Fan is a critical component. It is essential for every Diesel Locomotive. This assembly ensures radiator heat rejection. It manages the engine’s high thermal loads. Fan failure causes immediate engine derating. Sustained overheating leads to catastrophic damage. Ensure component reliability for fleet availability.

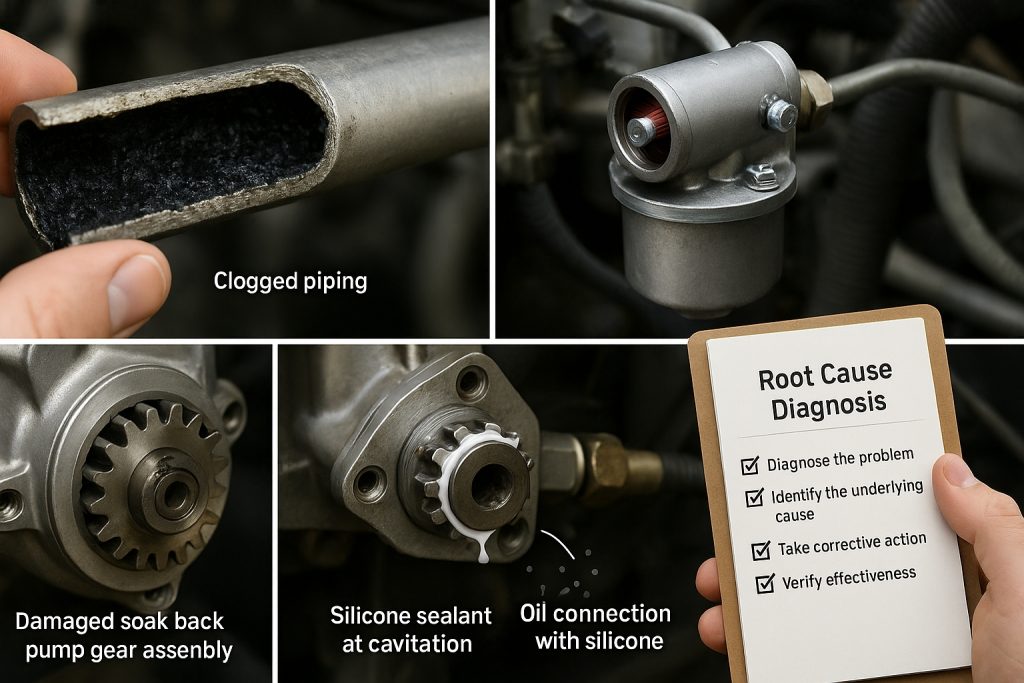

Decoding DMW Drg. No. EL/PT-0735 ALT-Z: Precision Sourcing

The drawing number DMW Drg. No. EL/PT-0735 ALT-Z is essential. DMW denotes Diesel Motor Works documentation. This identifier guarantees interchangeability and performance. It dictates the fan’s aerodynamic profile. It also specifies the required material composition. ‘ALT-Z’ signifies the latest official design revision. Sourcing managers must match this exact revision level.

Using an earlier revision may cause fitment failures. The 52 Inch Cooling Fan assembly interfaces precisely. This includes the locomotive’s surrounding structure. This structure often includes the Short Hood area. Precise fitment prevents cooling efficiency loss. It ensures the integrity of the Radiator Cooling Fan system.

Mitigating Risk: Why ALT-Z Compliance is Mandatory

Procuring the wrong fan version creates critical operational risk. Compliance prevents costly unscheduled downtime. Follow these steps to ensure drawing adherence.

- Verify the DMW specification sheet details completely.

- Confirm the ‘ALT-Z’ revision status before finalizing the purchase.

- Ensure material traceability matches the drawing requirements.

- Inspect the hub bore for compatibility with the drive shaft.

- Incorrect parts jeopardize the Dynamic Braking Grid function due to overheating.

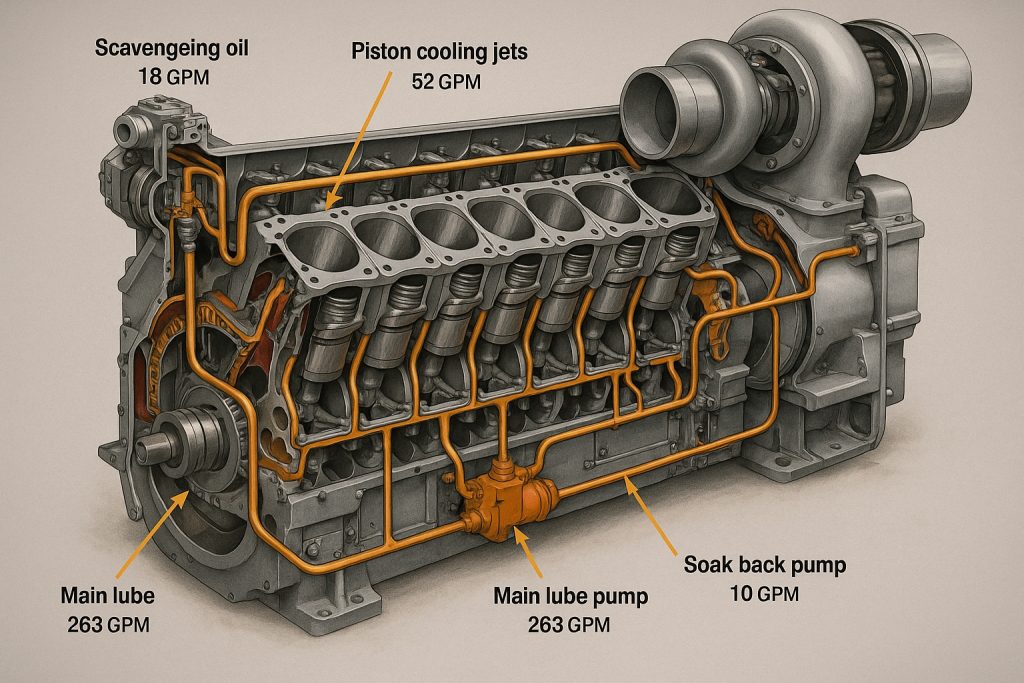

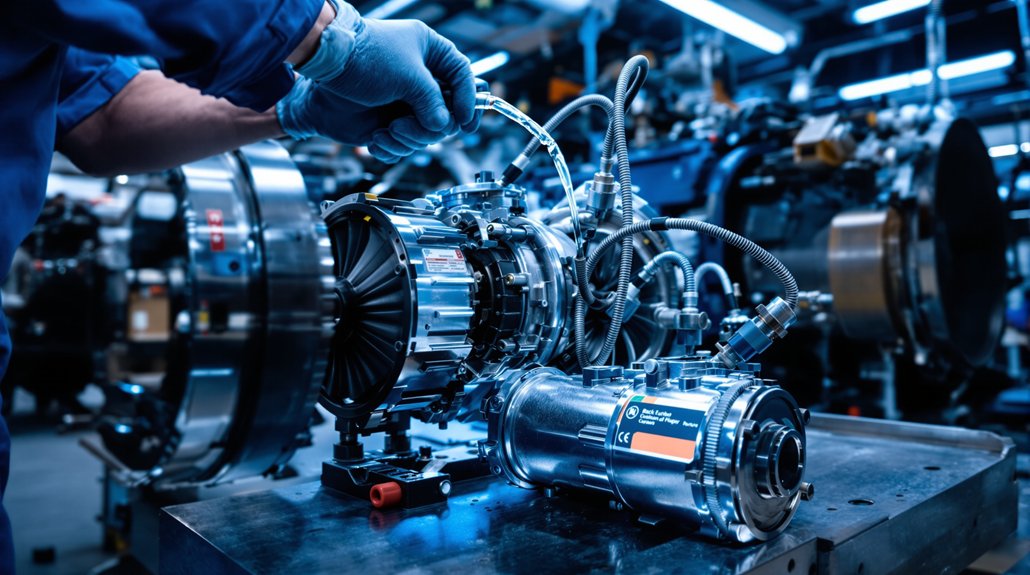

Technical Components of the 52 Inch Cooling Fan Assembly

The 52 Inch Cooling Fan assembly requires several components. These include the specialized blades, the hub, and the drive motor. The motor is typically a high-power unit. Older Diesel Locomotive systems use a DC Motor. This standard unit provides approximately 33 Kilowatts (Kw).

Modern EMD and ALCO systems often utilize an AC Motor. This allows for variable speed control. Optimized speed enables better thermal management efficiency. We supply components engineered for extreme vibration tolerance. This ensures longevity in the harsh locomotive environment.

| Specification Detail | Requirement/Value | Critical Function |

|---|---|---|

| Nominal Diameter | 52 Inches | Airflow Volume and Pressure |

| DMW Drawing Reference | EL/PT-0735 ALT-Z | Dimensional and Material Compliance |

| Motor Type (Standard) | DC Motor (33 Kw) | Reliable Torque Generation |

| Motor Type (Alternative) | AC Motor (67 Kw) | Variable Speed Capability |

| Material Requirement | High-Tensile Aluminum Alloy | Strength and Weight Optimization |

| Associated Systems | EMD, ALCO Diesel Locomotive | System Integration Guarantee |

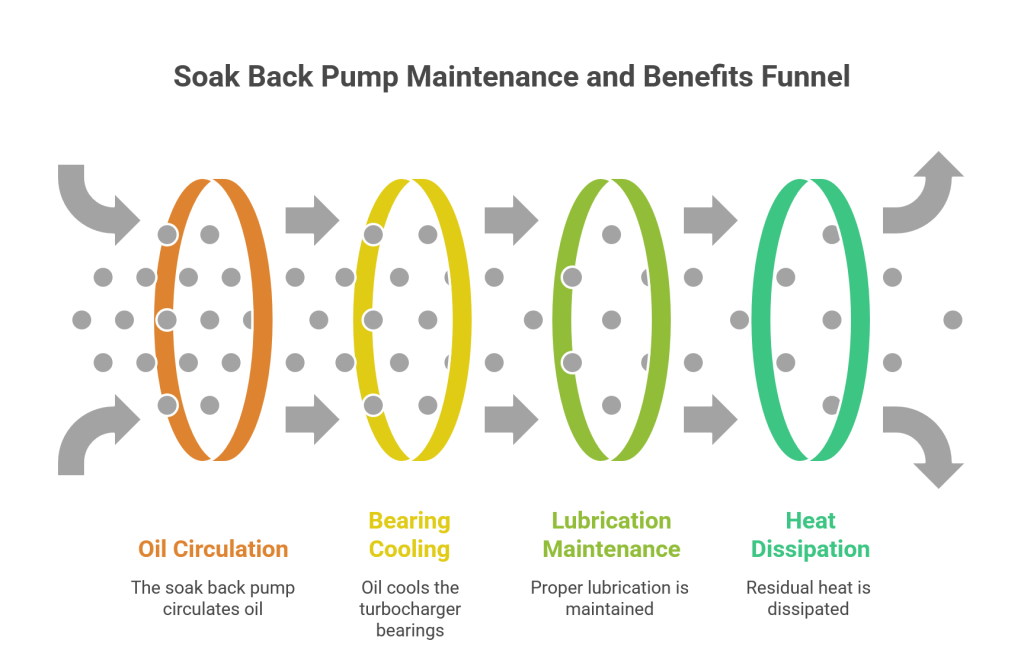

Ensuring Peak Airflow: Material and Blade Design

The Radiator Cooling Fan blade material is critical. It must withstand high rotational forces. The material must resist erosion from debris ingress. Proper blade geometry ensures maximum airflow volume. This airflow is necessary for efficient heat rejection.

This fan functions as the primary Blower Fan for the radiator bank. We guarantee material compliance to the exact DMW standard. This ensures the correct performance metrics are met. This prevents premature wear or catastrophic blade failure.

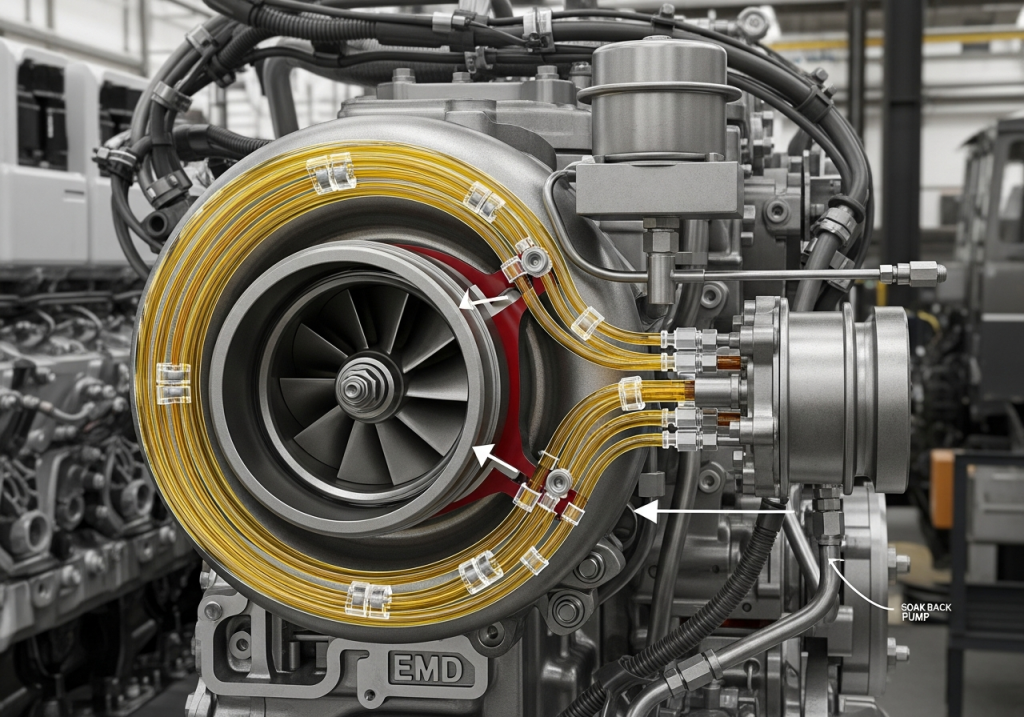

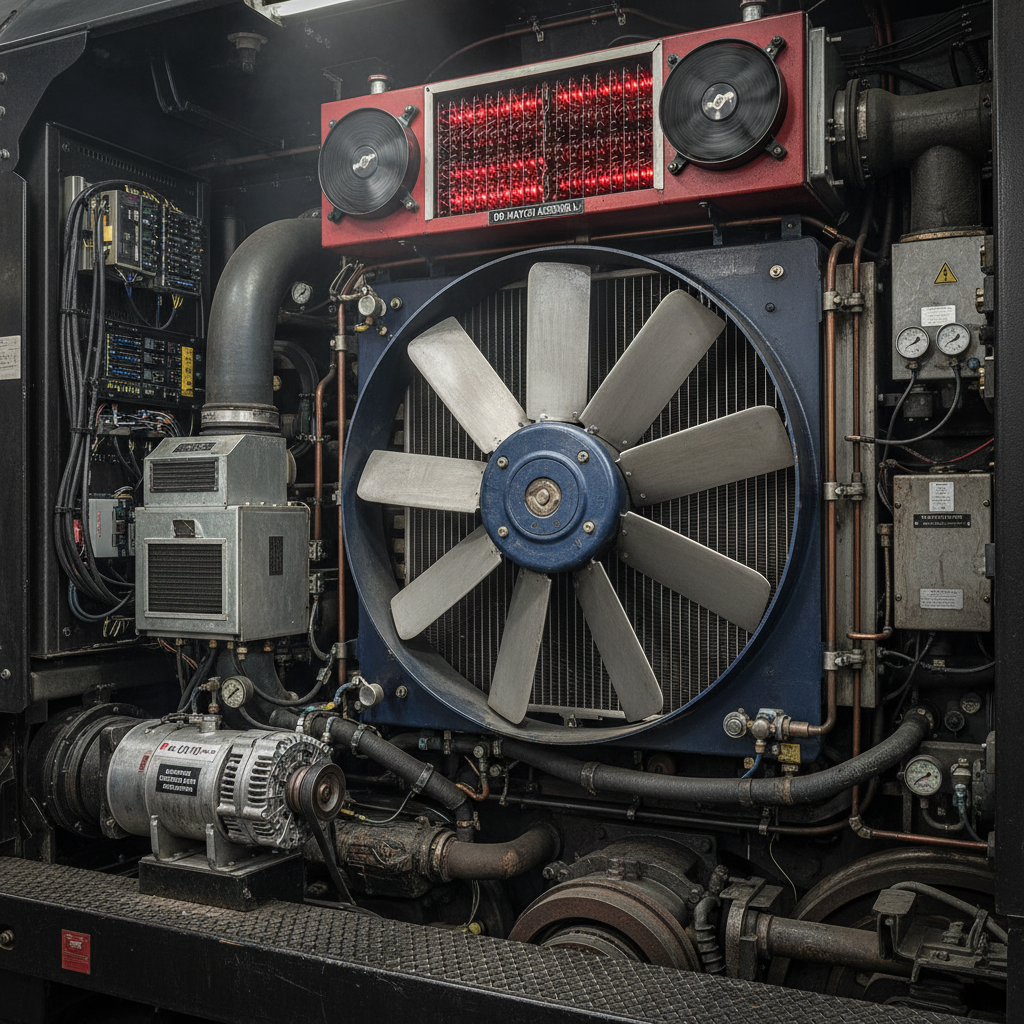

Impact of Fan Failure on Auxiliary Systems

Failure of the 52 Inch Cooling Fan has wide repercussions. Increased engine heat loads affect connected subsystems. High temperatures stress the Traction Motor Blower supply. The Machine Room Blower must work harder to compensate. Ensure the primary cooling system is robust. This prevents cascading failures in the auxiliary systems.

A failed fan also impacts the Auxiliary Power Unit (APU) efficiency. Maintaining the specified 52 Inch Cooling Fan performance protects the entire locomotive operation.

Integration with Auxiliary Locomotive Components

The 52 Inch Cooling Fan operates within the locomotive thermal management network. This critical network includes several vital blower systems. All subsystems must function optimally together. Proper integration prevents thermal runaway in the Diesel Locomotive.

Essential Blower and Ventilation Systems

The 52 Inch Radiator Cooling Fan handles the primary engine heat load. However, other components require dedicated cooling. These auxiliary systems maintain operational integrity.

The Machine Room Blower circulates air in the engine compartment. This prevents heat accumulation near sensitive electronic controls. The Traction Motor Blower provides cooling air to the electric motors. This sustains traction performance under heavy load.

The Oil Cooling Unit Blower regulates lubricant temperature stability. Sourcing managers must ensure all Blower Fans meet specification. Verify compatibility with ALCO and EMD locomotive platforms.

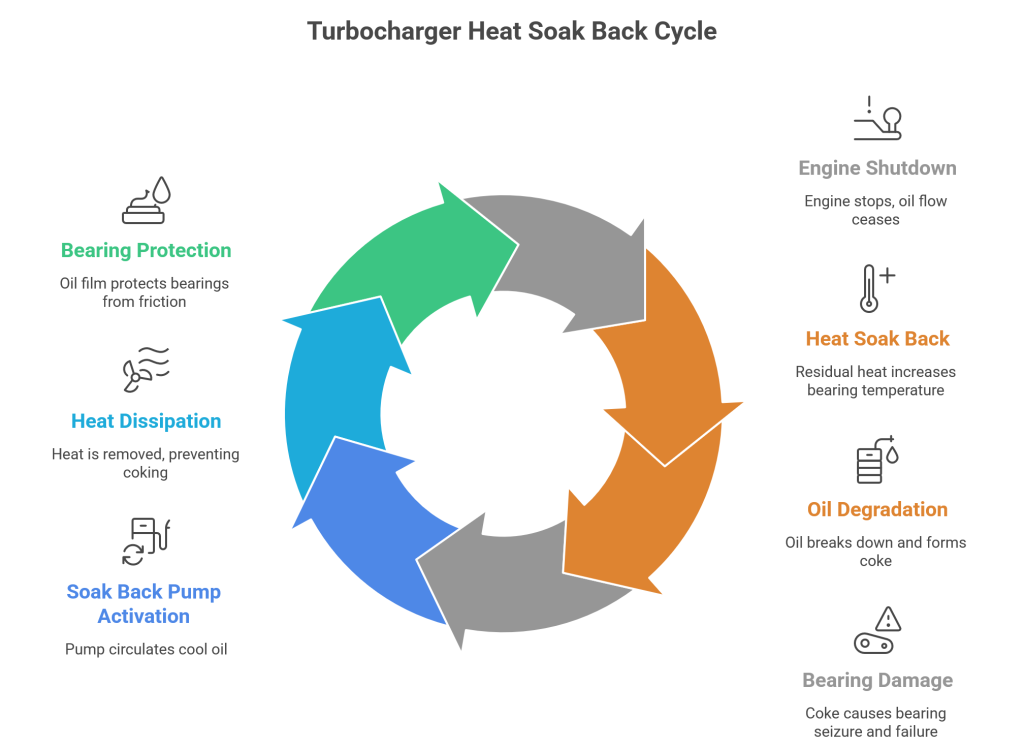

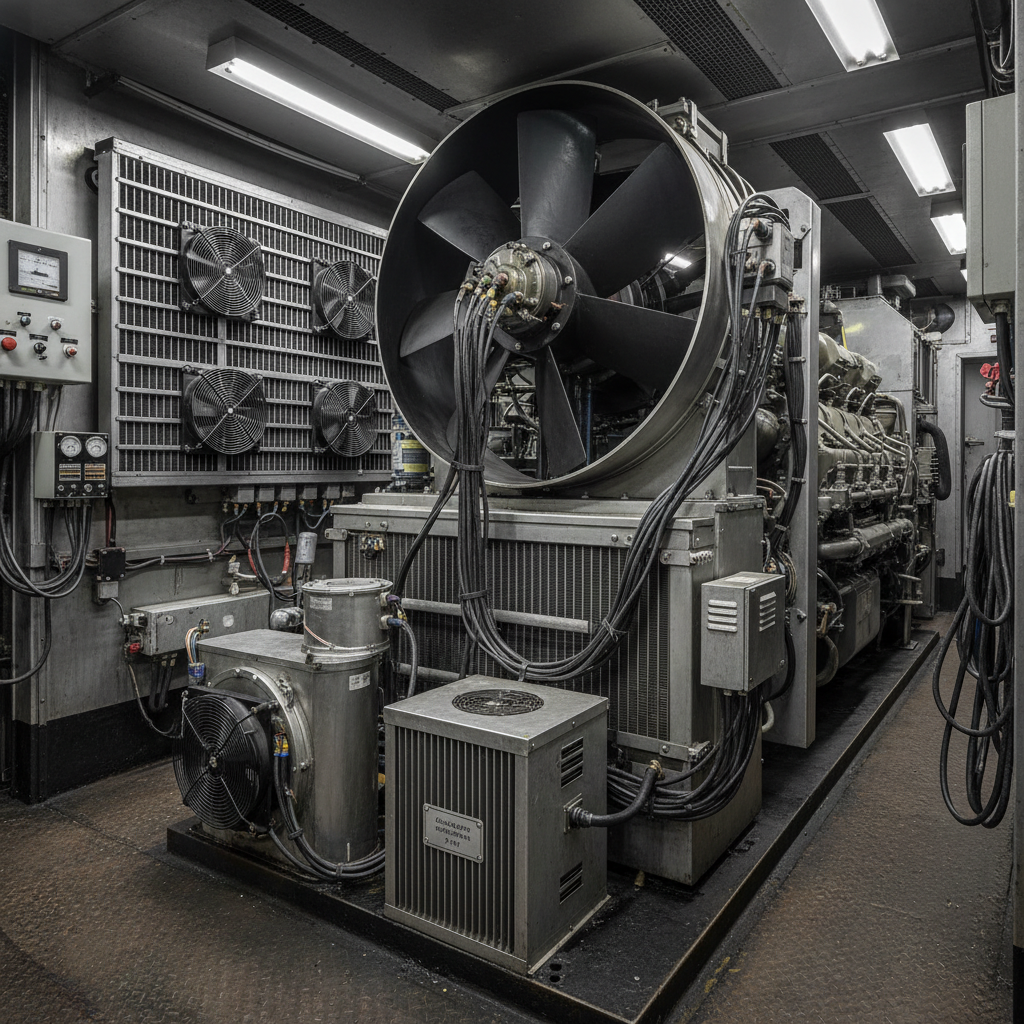

Managing Heat from Dynamic Braking

Locomotives utilize Dynamic Braking for speed reduction. This process converts kinetic energy into intense thermal energy. This heat must dissipate through the Dynamic Braking Grid.

The grid resistors are housed within the specific DB HATCH Assembly. This assembly requires its own dedicated cooling fans. This is often referred to as the EMD Grid Box or ALCO Grid Box.

Effective 52 Inch Cooling Fan operation reduces the ambient air temperature. This aids the overall cooling efficiency of the Dynamic Braking Grid. Thermal integrity is essential for safe operation.

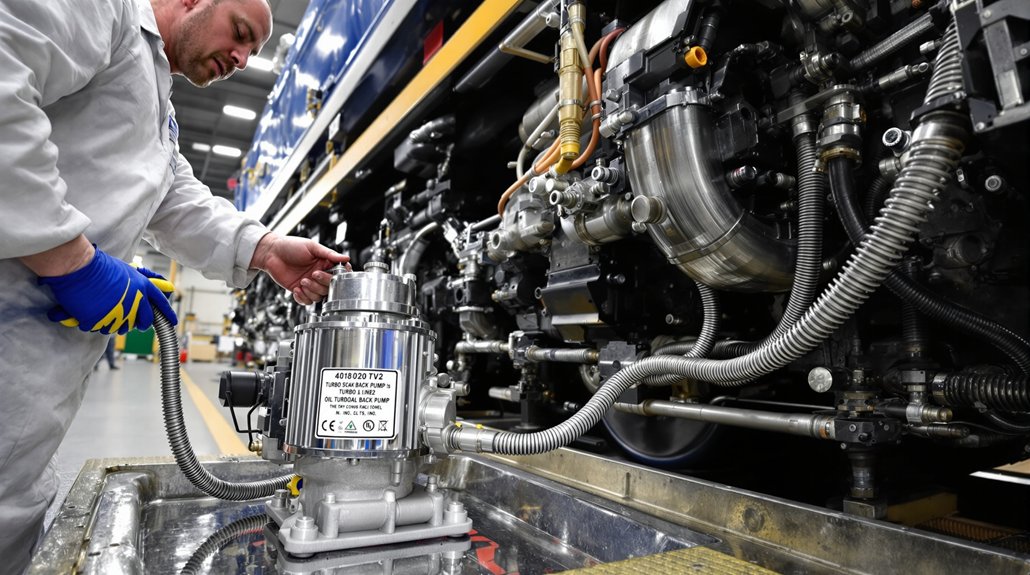

Powering Auxiliary Cooling Systems

The entire locomotive cooling network relies on reliable electrical supply. The 52 Inch Cooling Fan motor requires precise electrical input. Verify the motor type: DC Motor or AC Motor.

The Auxiliary Power Unit (APU) supplies essential power during standby. The APU Alternator maintains system readiness. The main engine utilizes a Permanent Magnet Alternator (PMA).

Ensure the PMA output meets requirements for the cooling system. This includes specifications for the 2.5 KW Alternator and the 7.5 KW Alternator versions. Correct power supply prevents premature component failure.

Critical Cooling Fan Sizing Verification

Precision sizing prevents fitment failures and efficiency loss. Sourcing managers must confirm the exact fan dimension. The 52 Inch Cooling Fan is common for many Diesel Locomotive models.

Do not confuse this component with the smaller 48 Inch Cooling Fan. Also, verify if your application requires the larger 54 Inch Radiator Cooling Fan. Using the specified DMW drawing guarantees correct component dimensions.

| Component | Primary Function | Required Verification |

|---|---|---|

| 52 Inch Cooling Fan | Primary Radiator Cooling | DMW Drg. No. EL/PT-0735 ALT-Z |

| Traction Motor Blower | Motor Cooling | Airflow rating (CFM) |

| DB HATCH Assembly Fans | Grid Resistor Heat Dissipation | Compatibility with EMD/ALCO Grid Box |

| Machine Room Blower | Electronics Ventilation | Motor voltage (DC/AC) |

Actionable Steps for Sourcing Managers

Reliable cooling components are mandatory for fleet availability. Follow these steps to ensure system integrity.

- Identify the exact DMW drawing number required for your fleet.

- Confirm the revision level matches the current ‘ALT-Z’ standard.

- Specify the correct motor type (DC Motor or AC Motor) for the 52 Inch Cooling Fan.

- Verify the Cooling Fan diameter against the 48 Inch Cooling Fan and 54 Inch Cooling Fan alternatives.

- Ensure component certification meets ALCO or EMD specifications.

Mikura International guarantees compliance with specified DMW drawings. Proper heat dissipation maximizes engine performance. This also maximizes the Dynamic Braking capacity of the Diesel Locomotive.

Sourcing high-quality Locomotive Components minimizes unplanned operational downtime.

Power Requirements for the 52 Inch Cooling Fan

The large 52 Inch Cooling Fan requires substantial electrical power. This fan handles critical thermal loads. Power draws often exceed standard auxiliary capacity. Sourcing managers must verify the power supply architecture.

Using incorrect power specifications guarantees operational failure. Reliable power is essential for continuous engine cooling. We provide certified replacement components for these critical systems.

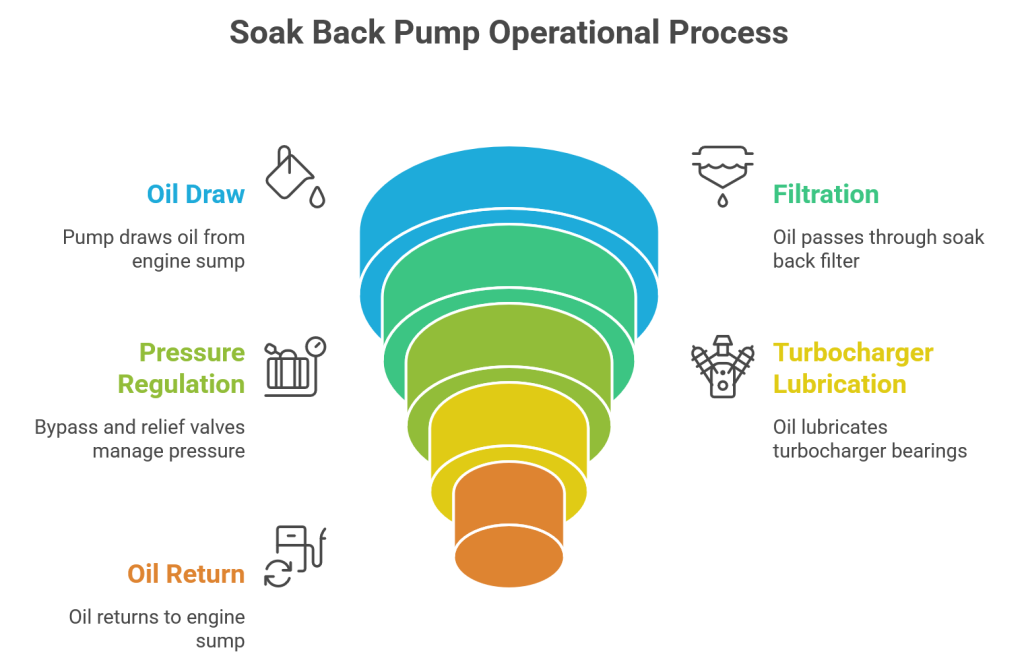

Optimizing Power Supply with the Auxiliary Power Unit

Most modern Diesel Locomotive fleets use an Auxiliary Power Unit (APU). The APU supplies power when the main engine is idle. It keeps critical systems energized during short stops. This ensures rapid system readiness.

The Auxiliary Power Unit directly supports the large cooling subsystems. It reduces wear on the primary engine during standby. This continuous support is vital for maintaining the cooling loop.

Selecting the Correct PM Alternator Rating

The APU typically uses a Permanent Magnet Alternator (PM Alternator). These units offer high efficiency and robust durability. Choosing the right alternator capacity is non-negotiable.

We supply alternators in various operational power ratings. Common sizes include the 2.5 KW Alternator and the higher output 7.5 KW Alternator. Matching the alternator output to the fan motor specifications is critical.

Undersized PM Alternator units fail to operate the high-draw 52 Inch Cooling Fan. Proper sizing guarantees reliable Radiator Cooling Fan performance. This prevents costly engine overheating and unplanned downtime.

Power Allocation for Locomotive Blower Systems

The auxiliary power system must support all ventilation needs. This includes the high-demand 52 Inch Cooling Fan load. It also powers the essential Traction Motor Blower units.

The auxiliary system further supports the Machine Room Blower and Oil Cooling Unit Blower. Ensure the APU Alternator output covers the total combined electrical load. Calculating peak power draw prevents system trips.

Supporting Dynamic Braking Cooling

High-capacity cooling fans are necessary for the Dynamic Braking Grid. Power is needed for fans cooling the Dynamic Braking components. The DB HATCH Assembly components require constant cooling airflow.

This prevents thermal damage to the Grid Resistors during braking operations. Reliable auxiliary power ensures the longevity of the Dynamic Braking Grid system.

Procurement Protocols for Certified Locomotive Components

The 52 Inch Cooling Fan handles extreme thermal loads. Component failure results in immediate engine shutdown. Sourcing managers require guaranteed quality and timely delivery.

Mikura International adheres to strict quality protocols. We ensure every replacement part meets the required DMW standard. This eliminates risks associated with substandard Locomotive Components.

Actionable Advice for DMW Specification Compliance

Follow these steps for optimal parts procurement. This process minimizes operational risk and delays.

- Confirm Supplier Certification: Ensure the supplier holds current ISO certification. This verifies commitment to quality management systems.

- Demand Material Traceability: Request documentation confirming material origin. This is vital for Cooling Fan blade integrity and long service life.

- Verify Dimensional Accuracy: Cross-reference physical dimensions against DMW Drg. No. EL/PT-0735 ALT-Z. Minor deviations cause major operational faults.

- Assess Inventory Buffer: Maintain sufficient stock of critical parts. This minimizes downtime during unexpected failures of the Radiator Cooling Fan system.

- Evaluate Lead Time: Choose suppliers who guarantee urgency in response. On-time delivery is crucial for maintenance schedules.

Quality Assurance Checkpoints for Cooling Systems

The reliability of the high-power 52 Inch Cooling Fan depends on rigorous inspection. We apply specific tests ensuring performance under load.

Failure to verify these checkpoints impacts other critical systems. These include the Dynamic Braking Grid and the Traction Motor Blower operation.

| Inspection Point | DMW Requirement Standard | Failure Consequence |

|---|---|---|

| Blade Pitch Angle | ± 0.5 Degrees Tolerance | Reduced airflow, thermal runaway risk. |

| Balancing Report | ISO 1940 Grade G6.3 | Excessive vibration, bearing failure. |

| Material Composition | Verified Alloy Certificate | Fatigue cracking, catastrophic blade separation. |

| Mounting Flange Fitment | Precise DMW Drg. EL/PT-0735 | Misalignment, damage to DC Motor assembly. |

Preventing Thermal Damage in Diesel Locomotive Operation

Proper function of the 52 Inch Cooling Fan is non-negotiable. It protects the engine from overheating. Overheating compromises engine longevity.

Sourcing managers must proactively manage component lifespan. This prevents emergency repairs on the Diesel Locomotive.

We provide components engineered for extreme environments. This includes parts for the Machine Room Blower and the Oil Cooling Unit Blower. Using certified parts ensures system harmony.

Reliable cooling supports efficient operation of the Auxiliary Power Unit (APU). It also protects related Grid Resistors during dynamic braking cycles.

Expert Insight

“The criticality of locomotive cooling systems means that failure analysis must go beyond material wear; we frequently trace catastrophic thermal damage back to precise engineering deviations, a failure in balancing, tolerance, or certified fitment that acts as the root cause for system collapse.” , Dr. Robert A Durham, PhD, PE, Failure Analysis Expert

Historical Precedent in Locomotive Thermal Management

Thermal management challenges span the history of railway motive power. Early locomotive designs prioritized effective heat removal. The shift to the Diesel Locomotive intensified this critical requirement.

Modern engines demand high-capacity cooling systems. Using the wrong component causes system failure. The 52 Inch Cooling Fan must meet precise thermal specifications.

From Steam Technology to Diesel Locomotive Requirements

The need for robust heat rejection is not new. Consider the historical context of the DRB Class 52 Steam Locomotive. This system managed immense thermal energy loads. It often used a specialized Condensing Tender for heat control.

This history established the need for rigorous design standards. Modern manufacturers like EMD and ALCO learned from these precedents. They require highly reliable Locomotive Components.

Today’s high-horsepower Diesel Locomotive engines generate extreme heat. This heat requires active management across several subsystems. The 52 Inch Cooling Fan is vital to engine protection.

The Role of the 52 Inch Radiator Cooling Fan

The 52 Inch Cooling Fan primarily operates as a Radiator Cooling Fan. It maintains optimal engine temperature during high output. Failure of this fan leads to immediate derating or shutdown.

Heat management extends beyond the engine itself. Auxiliary systems also require dedicated cooling. This includes cooling required for the Dynamic Braking Grid.

The Dynamic Braking system uses large Grid Resistors. These resistors dissipate massive amounts of electrical energy as heat. Specialized Blower Fans are required for this purpose.

Sourcing managers must specify the correct fan type. Ensure the part matches the DMW drawing standards. This guarantees compatibility with the existing Diesel Locomotive architecture.

| Component | Primary Function | Typical Diameter Range |

|---|---|---|

| Radiator Cooling Fan | Engine coolant heat rejection | 52 Inch Cooling Fan / 54 Inch Cooling Fan |

| Traction Motor Blower | Cooling of traction motors | Varies by horsepower |

| Machine Room Blower | Ventilation and general cooling | Standardized sizes |

| Dynamic Braking Grid Blower | Cooling of Grid Resistors | High CFM Blower Fans |

Ensuring Component Reliability

Reliability of the 52 Inch Cooling Fan is non-negotiable. Substandard parts threaten the entire operation. Sourcing managers must verify supplier quality protocols.

We specialize in certified replacement Locomotive Components. We ensure material integrity and dimensional accuracy. This minimizes thermal stress on the Diesel Locomotive engine block.

Specify certified parts for every application. This includes the 48 Inch Cooling Fan and the 52 Inch Cooling Fan. Proper cooling extends the lifespan of the engine.

Frequently Asked Questions

Sourcing managers frequently encounter complex technical questions. Specific component requirements dictate sourcing decisions. We provide clarity on the 52 Inch Cooling Fan and related Diesel Locomotive parts. Use this guide to ensure precise ordering.

Q1: What defines the DMW Drg. No. EL/PT-0735 ALT-Z specification?

This DMW drawing number specifies the exact dimensions. It defines material composition and performance standards. This ensures the 52 Inch Cooling Fan fits perfectly. It guarantees compliance with the original equipment manufacturer (OEM) design. This specification is crucial for reliable radiator cooling.

Q2: How does the 52 Inch Cooling Fan differ from 48 Inch and 54 Inch variants?

The diameter difference significantly impacts airflow volume. The 52 Inch Cooling Fan balances cooling capacity and power draw. The 48 Inch Cooling Fan may lack required thermal dissipation. The 54 Inch Cooling Fan might require different motor mounting. Always confirm the required fan size for your specific Diesel Locomotive model.

Q3: Is the Cooling Fan interchangeable between EMD and ALCO locomotives?

Direct interchangeability is rare due to mounting differences. EMD and ALCO use varying engine block designs. They require specific fan blade pitch and housing arrangements. Always cross-reference the drawing number against your engine series. This prevents costly fitment errors.

Q4: What role do auxiliary blowers play in locomotive thermal management?

Effective heat management requires several specialized blowers. The main Radiator Cooling Fan manages engine coolant temperature. The Traction Motor Blower cools the traction equipment. The Machine Room Blower maintains ambient component temperatures. The Oil Cooling Unit Blower manages critical lubrication system heat. All must function for optimal locomotive operation.

Blower System Hierarchy

The cooling system relies on synchronized airflow management.

- Primary Cooling: 52 Inch Cooling Fan (Radiator Cooling Fan)

- Motor Cooling: Traction Motor Blower

- Component Cooling: Machine Room Blower

- Oil Management: Oil Cooling Unit Blower

Specify the correct Blower Fans for maximum efficiency.

Q5: How does the Cooling Fan system affect Dynamic Braking performance?

The Cooling Fan system indirectly supports dynamic braking. Dynamic Braking generates immense heat in the Grid Resistors. While separate, overheating the engine reduces available power. Reduced power limits the effectiveness of the Dynamic Braking system. Ensure the DB HATCH Assembly is structurally sound and ventilated.

Q6: What power requirements are necessary for high-capacity Cooling Fans?

High-capacity Radiator Cooling Fans demand reliable auxiliary power. Many modern units utilize an AC Motor. This contrasts with older DC Motor designs. Verify the required voltage and phase specifications. The Auxiliary Power Unit (APU) provides standby electrical supply. Ensure your 2.5 KW Alternator or 7.5 KW Alternator output is sufficient.

Q7: When should I consider replacing the entire Fan Assembly versus just the blades?

Inspect the hub and bearing assembly first. Blade replacement is cost-effective for localized damage. Replace the entire assembly if bearing noise is excessive. Major structural fatigue in the hub demands total replacement. This prevents catastrophic in-service failure.

Q8: Does Mikura International supply Permanent Magnet Alternators for these applications?

Yes, we supply various auxiliary power generation components. This includes the Permanent Magnet Alternator units. These alternators are highly efficient and reliable. They are essential for powering the Blower Fans and other auxiliaries. We ensure the alternator matches your locomotive’s specific requirements.

Q9: How do I ensure I receive the highest quality Grid Resistors for Dynamic Braking?

Focus on material certification and manufacturing precision. Grid Resistors must withstand extreme thermal cycling. We verify compliance with EMD and ALCO specifications. High quality components minimize resistance variation. This guarantees consistent Dynamic Braking performance.

Q10: What are the risks of using a non-certified 52 Inch Cooling Fan?

Non-certified components pose significant operational risks. Risks include incorrect pitch resulting in low airflow. Low airflow causes engine overheating and thermal shutdown. Dimensional inaccuracies lead to vibration and premature bearing failure. Always choose certified Locomotive Components for reliability.

Frequently Asked Questions

What is the primary function of the 52 Inch Cooling Fan?

This component functions as the primary Radiator Cooling Fan.

It draws ambient air across the radiator core.

This action removes thermal energy from the engine coolant.

Effective heat management prevents Diesel Locomotive engine overheating.

This ensures optimal operational efficiency.

Why is the DMW Drg. No. EL/PT-0735 ALT-Z reference critical?

The DMW drawing number defines the exact design specification.

It guarantees precise fitment of the fan assembly.

This reference ensures compliance with all material standards.

Using the correct reference prevents costly system incompatibility issues.

Always verify this number before ordering any 52 Inch Cooling Fan.

Is the 52 Inch Cooling Fan compatible with EMD and ALCO fleets?

The application depends on the specific cooling system design.

The 52 Inch Cooling Fan is common across heavy-duty platforms.

Verify the requirement against the official parts manual.

We provide accurate Locomotive Components for both EMD and ALCO fleets.

Some models require a 48 Inch Cooling Fan or a 54 Inch Cooling Fan.

What role does the Permanent Magnet Alternator (PM Alternator) play?

The PM Alternator generates auxiliary electrical power.

It is often integrated into the Auxiliary Power Unit (APU).

This power supplies the fan’s DC Motor or AC Motor.

Common capacities include the 2.5 KW Alternator and 7.5 KW Alternator.

Consistent power ensures continuous Radiator Cooling Fan operation.

How does the Cooling Fan relate to the Dynamic Braking Grid?

The 52 Inch Cooling Fan handles main engine heat rejection.

The Dynamic Braking Grid requires separate forced air cooling.

Grid cooling uses specific Blower Fans within the DB HATCH Assembly.

These blowers cool the Grid Resistors inside the EMD Grid Box or ALCO Grid Box.

Efficient main engine cooling reduces the locomotive machine room temperature.

This lower ambient temperature improves overall Dynamic Braking performance.

What other blower systems support locomotive heat management?

Several specialized Blower Fans manage heat in subsystems.

The Traction Motor Blower cools the traction motors.

The Machine Room Blower circulates air through the engine compartment.

The Oil Cooling Unit Blower manages lubrication system temperatures.

All these components are essential Locomotive Components.

Ensure precise sourcing for every specialized blower unit.