Engine downtime is extremely costly for locomotive operations. Sourcing managers face challenges ensuring optimal engine performance and longevity. Inferior Piston Rings lead directly to increased engine oil consumption, poor power output, and severe mechanical friction losses. Selecting the correct replacement components prevents catastrophic engine piston failure and controls harmful Blow-By.

Overcome these pain points immediately:

- Specify materials resistant to high engine temperatures.

- Verify proper thermal expansion tolerances before purchase.

- Prioritize efficient Oil Control Ring design.

- Measure the Cylinder Wall wear accurately.

- Use certified suppliers for guaranteed part quality.

- Confirm components comply with OEM specifications.

- Minimize engine friction losses by checking ring surface finish.

The Critical Role of the Piston Ring in Locomotive Engines

The Piston Ring is vital for any heavy-duty Internal Combustion Engine. These metallic split rings are essential components fitted into grooves on the engine piston. They create a seal between the piston and the Cylinder Wall. This sealing function in the Combustion Chamber is critical for maintaining engine compression.

Failure of the Piston Ring system results in immediate power loss. It also increases engine oil consumption dramatically. We focus only on components designed for reliable locomotive and marine applications.

Understanding Piston Ring Types

A typical locomotive engine piston uses three primary types of Piston Rings. Each ring performs a distinct function within the reciprocating engine cycle. Proper selection involves understanding these roles precisely.

1. Compression Rings

Compression Rings are the uppermost rings on the engine piston. Their primary role is sealing Combustion Chamber gases. This prevents high-pressure combustion gases from escaping into the Crank Case. Excessive gas leakage is known as Blow-By. Effective sealing ensures maximum power output.

2. Oil Control Rings

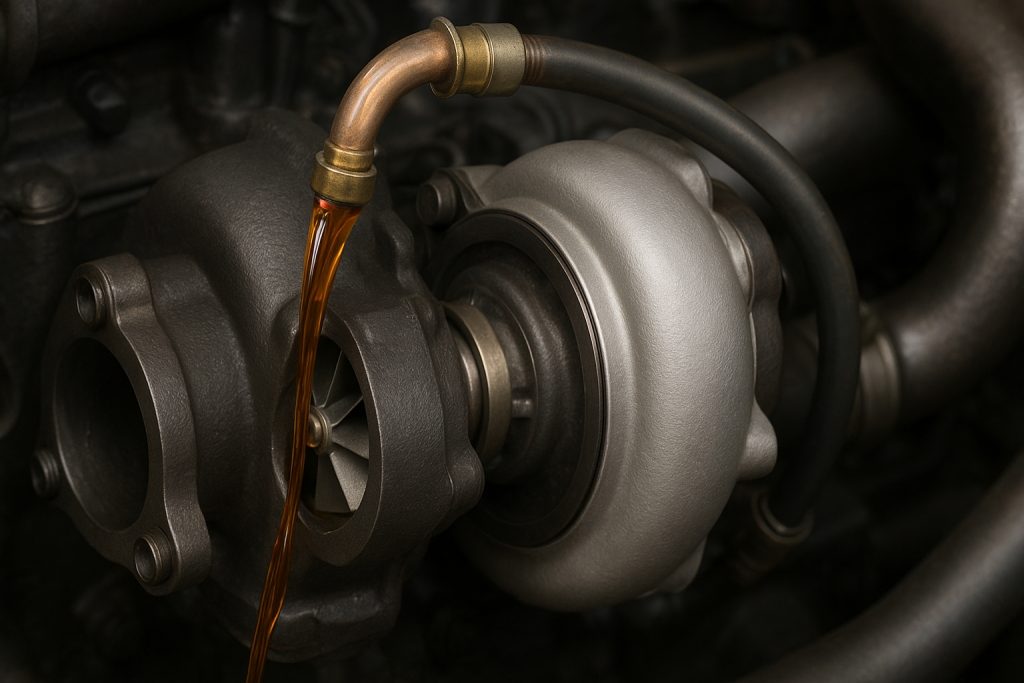

The Oil Control Ring is the lowest ring in the piston assembly. Its function is regulating the oil film on the Cylinder Wall. It scrapes excess Oil back into the Crank Case. This prevents oil from entering the Combustion Chamber where it burns off. Efficient oil scraping minimizes engine oil consumption.

Primary Functions of the Piston Ring System

The entire Piston Ring system works synergistically. It manages power, lubrication, and temperature within the cylinder. Selecting the correct Piston Ring design directly impacts engine longevity.

| Function | Description | Pain Point Addressed |

|---|---|---|

| Sealing | Maintains compression by sealing Combustion Chamber gases. | Prevents power loss and excessive Blow-By. |

| Heat Transfer | Moves heat from the engine piston to the cooler Cylinder Wall. | Minimizes Piston Seizure risk and manages thermal expansion. |

| Oil Regulation | Regulating oil film thickness on the Cylinder Wall. | Controls high engine oil consumption. |

Evolution and Material Science in Piston Rings

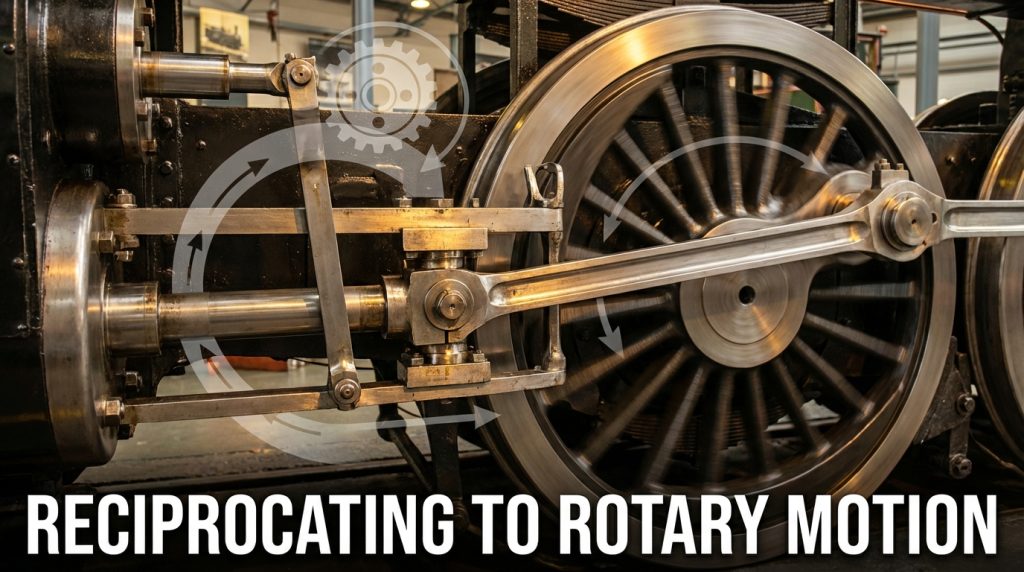

The concept of the metallic split ring dates back to the mid-19th century. Early designs, crucial for the Steam Engine, were developed by figures like Neil Snodgrass and John Ramsbottom. Modern locomotive applications require far greater material strength.

Today’s Piston Rings must withstand extreme high temperatures and pressures. Material choice directly impacts performance and durability.

Material Selection: Cast Iron vs. Steel Rings

Traditionally, Cast Iron rings dominated the industry. Cast Iron offers excellent wear characteristics and natural porosity for ring lubrication. However, modern heavy-duty engines increasingly utilize Steel rings.

Steel rings provide superior strength and fatigue resistance. This allows for thinner cross-sections, reducing engine friction losses. Both materials require specialized coatings to maximize lifespan.

Common coatings include Chromium plating and Nitride treatment. Chromium enhances wear resistance against the Cylinder Wall. Nitride diffusion hardening improves surface hardness and thermal stability. These coatings are essential for managing piston thermal expansion in high-output engines.

Preventing Engine Failure: Blow-By and Piston Seizure

Excessive Blow-By occurs when the ring gap or seal fails. This contaminates the Oil in the Crank Case. Contaminated oil accelerates wear throughout the engine.

Piston Seizure is a catastrophic failure. It often results from insufficient ring lubrication or overheating due to poor Heat Transfer. Utilizing advanced materials and precise ring gap configuration prevents these failures. Reliable suppliers ensure dimensional accuracy, minimizing the risk of ring binding failure.

Expert Insight

“The integrity of engine performance hinges on precision engineering; utilizing advanced alloys and coatings, coupled with tools like Finite Element Analysis, is essential to manage thermal stress and prevent catastrophic failures like Blow-By or Piston Seizure.” , Advanced Piston Engineering Specialist

Preventing Catastrophic Engine Failure

Locomotive sourcing managers require maximum component lifespan. Premature failure of the Piston Ring system causes severe downtime. This results in costly repairs and reduced operational efficiency. High Blow-By contaminates the Oil rapidly. This accelerates wear inside the Internal Combustion Engine. Proper sealing prevents excessive engine oil consumption. Selecting the correct rings minimizes these operational risks immediately.

The Piston Ring system is vital for sealing the Combustion Chamber. It regulates oil film thickness and minimizes engine friction losses. Choosing the right component prevents Piston Seizure and maintains peak performance.

Mitigating Risks in Reciprocating Engine Operation

- Verify the required cylinder gap specification precisely. This manages piston thermal expansion effectively.

- Inspect the Cylinder Wall surface finish before ring installation. Surface integrity is crucial for sealing.

- Select ring materials (e.g., specialized Cast Iron or Steel rings) matching high temperatures.

- Use specialized tools to prevent Piston Ring distortion during assembly.

- Confirm proper ring lubrication to establish hydrodynamic lubrication.

- Monitor engine oil consumption trends rigorously for early detection of wear.

- Choose rings engineered to resist Piston Seizure under continuous heavy load.

- Ensure effective Heat Transfer away from the engine piston crown.

Reliable Piston Ring design is key to preventing wear within the Crank Case. Effective oil scraping by the Power Assembly Compression reduces contamination. This ensures the longevity of the entire power assembly.

Core Functions of the Locomotive Piston Ring

The Piston Ring is a fundamental component in every heavy-duty Reciprocating Engine.

These specialized metallic split rings are mounted on the Engine Piston.

They ensure reliable operation of the Internal Combustion Engine.

The rings execute three essential tasks simultaneously for maximum output.

Selecting the right ring material directly impacts engine lifespan.

Sealing and Blow-By Prevention

The Compression Rings create a vital seal.

They effectively seal the Combustion Chamber pressure.

This sealing prevents combustion gases from escaping the cylinder.

Gas leakage past the Piston is known as Blow-By.

Excessive Blow-By contaminates the Oil in the Crank Case.

Maintaining high pressure ensures maximum power delivery.

Effective sealing of the Combustion Chamber pressure minimizes Engine friction losses.

Poor sealing severely reduces fuel efficiency and requires more frequent maintenance.

Thermal Management and Heat Transfer

Piston Rings are critical for managing heat.

They facilitate necessary Heat Transfer from the hot Piston crown.

This heat moves efficiently to the cooler Cylinder Wall.

This transfer prevents excessive Piston Thermal Expansion.

Uncontrolled heat leads to component stress and potential Piston Seizure.

Managing heat is crucial when operating at sustained High Temperatures.

Proper ring material selection supports optimal thermal balance.

Regulating Oil Consumption

The final function is precise oil control.

The specialized Oil Control Ring manages lubrication.

It scrapes excess Oil from the Cylinder Wall surface.

This process is defined as Oil Scraping.

The scraped oil returns to the sump for recirculation.

This action prevents excessive Engine Oil Consumption.

It also prevents oil from entering the Combustion Chamber and burning.

Proper Ring Lubrication requires maintaining a precise oil film thickness.

Effective regulation of oil consumption reduces operational costs significantly.

Materials Science: Cast Iron vs. Steel Rings

The required performance dictates the material choice.

Modern locomotive engines typically use high-grade Cast Iron Rings or specialized Steel Rings.

Cast Iron offers excellent wear resistance and graphite retention.

This material provides inherent self-lubricating qualities.

Steel Rings, often alloyed with Chromium or treated with Nitride, provide superior strength.

These rings tolerate higher loads and extreme High Temperatures.

Advanced Piston Ring Design often incorporates plasma deposition coating.

This coating enhances durability and minimizes mechanical friction loss.

Choosing the correct alloy is essential for demanding operational cycles.

It directly impacts the life cycle of the Internal Combustion Engine.

Evolution and Material Science of Piston Rings

The performance of the modern Internal Combustion Engine relies on historical innovation. Effective sealing was necessary long before the diesel locomotive era. John Ramsbottom patented the successful metallic split Piston Ring in 1852. This invention revolutionized the early Steam Engine design. Prior sealing methods, like those by Neil Snodgrass, were less reliable. This metallic split ring concept remains central to Piston Ring design today.

From Steam Engines to High-Performance Locomotives

The original metallic split ring addressed early sealing challenges. It managed pressure within the Steam Engine cylinder. Modern locomotive engines demand much higher operational tolerances. These engines experience extreme high temperatures and pressure loads. The Piston Ring must maintain complete Combustion Chamber Sealing. Failure to seal causes significant Blow-By into the Crank Case. Blow-By reduces power output and contaminates the Oil.

The evolution of Piston Ring design focuses on efficiency. It minimizes mechanical friction loss within the cylinder. It also enhances Heat Transfer from the Piston to the Cylinder Wall. Proper management of Piston Thermal Expansion is essential for reliability.

Metallurgy of Modern Locomotive Piston Rings

The chosen materials must withstand intense mechanical and thermal stress. Sourcing managers must select materials matched to engine duty cycles. Modern rings utilize advanced metallurgy for demanding Reciprocating Engine applications.

High-grade Cast Iron Rings are the foundational material. Cast Iron offers excellent wear resistance and thermal stability. It provides reliable performance for standard locomotive operations. However, high-output engines require superior material strength. Steel Rings are increasingly specified for severe duty cycles. Steel Rings provide greater tensile strength and resistance to fatigue. This greater strength prevents Piston Seizure under extreme load conditions.

Critical Surface Treatments for Sealing

Raw Cast Iron or Steel Rings alone are insufficient for modern requirements. Surface treatments are essential for managing Engine Oil Consumption. They also ensure longevity against the Cylinder Wall at high temperatures. These coatings optimize the primary functions of the Piston Ring.

One critical coating is hard Chromium plating. Chromium offers superior hardness and resistance to abrasive wear. It ensures effective Oil Scraping and regulates Oil levels. This plating is vital for the top Compression Rings. Another advanced treatment is Nitride coating. Nitride processes improve surface hardness and corrosion resistance. This treatment resists chemical attack and minimizes friction. These coatings ensure proper Ring Lubrication and support effective Ring Gap configuration.

Selecting the Optimal Piston Ring Design for Locomotive Engines

Heavy-duty locomotive applications require highly specialized Piston Ring Design. Incorrect selection leads to premature wear and engine failure. Optimal ring choice ensures superior Combustion Chamber Sealing integrity. It also minimizes Engine Friction Losses and manages oil usage effectively. These five ring types are essential for maximizing Internal Combustion Engine reliability.

1. Chromium-Coated Compression Rings

These are typically the primary Compression Rings. They are manufactured from high-strength Cast Iron. A thick layer of hard Chromium plating is applied. This coating drastically increases wear resistance against the Cylinder Wall. These rings provide superior sealing and manage high operating High Temperatures. They are crucial for minimizing Blow-By in the Combustion Chamber.

2. Nitride-Treated Steel Rings

Steel Rings offer significantly higher tensile strength than standard Cast Iron. Nitriding is a precise surface hardening process. This treatment enhances resistance to scuffing and fatigue failure. These rings maintain performance under extremely high thermal and mechanical loads. They are the preferred choice for powerful, high-output Reciprocating Engine designs.

3. Keystone Compression Rings

The Keystone Design features a specific tapered cross-section. This taper promotes axial movement within the Engine Piston groove. This motion prevents carbon deposits from accumulating. Preventing deposits stops ring sticking and performance degradation. This design is critical when using lower quality fuels in the Internal Combustion Engine.

4. Cast Iron Oil Control Rings

Effective regulation of oil usage is vital for engine longevity. These specialized Oil Control Rings manage Engine Oil Consumption. High-quality Cast Iron Rings conform perfectly to the Cylinder Wall profile. They use spring expanders for uniform radial pressure. Their primary function is aggressive Oil Scraping to return Oil to the Crank Case.

5. Plasma Deposition Coated Rings

These advanced rings utilize a plasma vapor deposition process. This technique applies materials like Molybdenum or specialized ceramics. This coating drastically minimizes Engine Friction Losses. It also ensures efficient Heat Transfer away from the piston. This improved durability prevents issues like Piston Seizure. These rings utilize Plasma Deposition Coating for maximum lifespan.

Expert Insight

“The modern internal combustion engine relies on advanced engineering techniques, utilizing specialized coatings, optimized materials, and precision honing to create piston systems that deliver superior sealing, drastically reduced friction, and maximize durability.” , Performance Engineering Analyst

Optimizing Performance: Piston Ring Material Selection

Material choice directly impacts locomotive engine reliability. Sourcing managers must evaluate thermal stress resistance. The correct material dictates Piston Ring longevity and maintenance costs. High temperatures and extreme pressures demand specific metallurgy. We analyze materials critical for heavy-duty Internal Combustion Engine operation.

The material must effectively manage heat and friction. It must also maintain perfect Combustion Chamber Sealing integrity. Incorrect material selection accelerates wear on the Cylinder Wall. This leads directly to increased Engine Oil Consumption and power loss.

Comparative Analysis of Piston Ring Materials

Locomotive Piston Ring sets rely primarily on advanced Cast Iron or Steel Rings. Each material offers specific advantages based on its ring position. Review the properties below to guide your sourcing decisions.

| Material Type | Typical Ring Use | Primary Benefit | Wear Resistance | Thermal Stability |

|---|---|---|---|---|

| High-Grade Cast Iron | Oil Control Ring, Lower Compression Rings | Excellent Conformity to Cylinder Wall, Cost-Effective | Good | Moderate (Suitable for Oil Scraping) |

| Chromium-Coated Cast Iron | Top Compression Rings (High Stress) | Superior Scuffing Resistance against Cylinder Wall | Very High | High |

| Nitride Steel | High Output Compression Rings | High Strength, Excellent Fatigue Resistance | Excellent | Very High (Resists Piston Seizure) |

| Plasma Coated Steel | All Compression Positions (Premium) | Reduced Engine Friction Losses, Improved Heat Transfer | Superior | Maximum (Handles High Temperatures) |

Metallurgical Requirements for Heavy-Duty Engines

Standard Cast Iron Rings provide reliable basic performance. However, modern high-output Internal Combustion Engine designs require enhancements. These enhancements minimize Blow-By and maximize efficiency.

Chromium plating drastically increases surface hardness. This coating is essential for the top Compression Rings. It minimizes abrasive wear against the Cylinder Wall. The Chromium layer extends the life cycle of the Piston Ring.

Steel Rings, specifically Nitride Steel, offer required tensile strength. This material prevents ring breakage under severe mechanical stress. Nitride treatment enhances surface hardness and fatigue resistance.

Plasma deposition coatings are the premium choice for Heat Transfer improvement. These coatings drastically reduce Engine Friction Losses. They optimize the flow of heat away from the Piston. Selecting the correct coated Steel Rings prevents thermal failure and Piston Seizure. Always specify materials engineered for sustained High Temperatures.

The Oil Control Ring material must ensure effective oil regulation on the Cylinder Wall. High-Grade Cast Iron is often sufficient for efficient Oil Scraping.

Actionable Advice for Sourcing Managers

Quality assurance is mandatory for sourcing managers. Inferior Piston Ring sets compromise the entire Internal Combustion Engine. Mikura International components meet stringent OEM standards. We supply reliable parts for ALCO, EMD, and GE engines.

Material choice directly impacts maintenance schedules. Verify supplier ISO certification and component traceability. This prevents catastrophic events like Piston Seizure. Proper material selection maximizes fuel efficiency.

The principle of the Piston Ring dates back to figures like John Ramsbottom. Modern rings must achieve perfect Combustion Chamber Sealing pressure. This applies equally to locomotive and marine Reciprocating Engine designs.

Critical Piston Ring Specification Checks

Sourcing efficiency requires precise technical verification. Focus on these four critical areas during procurement.

- Verify Material and Coating: Confirm Cast Iron or Steel Rings meet specific hardness requirements. Verify the presence of protective coatings. Chromium or Nitride coatings reduce Engine Friction Losses and extend the life of the Cylinder Wall.

- Control Ring Gap Configuration: Incorrect end gaps cause excessive Blow-By. This significantly reduces pressure within the Combustion Chamber. Ensure the gap specification accounts for operating High Temperatures and Thermal Expansion rates.

- Optimize Oil Management: Select robust Oil Control Ring designs. Effective oil regulation minimizes Engine Oil Consumption. Look for advanced Oil Scraping features. Efficient oil control protects the Crank Case environment.

- Ensure Thermal Performance: The ring must facilitate efficient Heat Transfer from the Piston crown. Proper Ring Lubrication is vital for preventing wear. Choose materials optimized for specific thermal loads.

Piston Ring Material Comparison

Selecting the correct metallurgy is paramount. Different Piston Ring materials suit varying engine demands. Consider the stress profile of your specific Internal Combustion Engine application.

| Piston Ring Material | Primary Benefit | Typical Locomotive Application |

|---|---|---|

| High-Strength Cast Iron | Excellent wear resistance, Cost-effective. | Standard Compression Rings in EMD engines. |

| Steel Alloy (Chrome Plated) | Superior tensile strength, Handles extreme High Temperatures. | High-output marine Piston assemblies. |

| Steel Alloy (Nitride Coated) | Enhanced surface hardness, Resistance to scuffing. | Marine Reciprocating Engine applications requiring longevity. |

Verify that the chosen material supports sufficient Oil film stability. This is crucial for hydrodynamic lubrication.

Frequently Asked Questions (FAQ)

What is the primary cause of Piston Ring failure in locomotives?

Abrasive wear is the leading cause of Piston Ring failure. This results from contaminated Oil or poor Ring Lubrication. High thermal loads cause severe stress and potential ring binding. Excessive Blow-By accelerates this damage significantly. Incorrect installation affects the critical Cylinder Gap. This improper gap leads directly to catastrophic wear and potential Piston Seizure.

How do Compression Rings prevent Blow-By?

Compression Rings create a dynamic seal within the Cylinder Wall. Combustion pressure forces the ring against the piston groove and the Cylinder. This action seals the Combustion Chamber. This barrier prevents high-pressure gases from entering the Crank Case. Effective sealing minimizes power loss and reduces Engine Friction Losses.

Why are Steel Rings often Nitride-treated or Chromium-coated?

Steel Rings and high-quality Cast Iron Rings require surface hardening. Treatment with Nitride or Chromium enhances durability. This dramatically improves resistance against scuffing and abrasive wear. These coatings are crucial for managing performance at High Temperatures. They ensure the long-term integrity of the Combustion Chamber Sealing.

What is the function of the Oil Control Ring?

The Oil Control Ring is essential for regulating oil film thickness. This ring scrapes excess Oil from the Cylinder Wall. It directs the oil back to the Crank Case via drainage holes. Proper oil control prevents high Engine Oil Consumption. This ensures hydrodynamic lubrication without excess oil burning.

Who were key innovators in Piston Ring design?

The modern metallic split Piston Ring was invented by John Ramsbottom in 1852. This was critical for improving the Steam Engine. Later, Neil Snodgrass contributed significantly to advanced Piston Ring Design. His work focused on improving oil management and sealing in the modern Internal Combustion Engine.

How does Piston Ring material affect Heat Transfer?

Piston Rings are vital components for Heat Transfer. They move heat from the Piston crown to the cooler Cylinder Wall. High-quality Cast Iron or Steel rings offer excellent thermal conductivity. Managing heat prevents excessive Thermal Expansion. This maintains the critical clearance required to avoid ring binding.

You may also like to read – Piston ring – Wikipedia