Where can I buy genuine EMD locomotive thrust washers?

This is the urgent question facing maintenance managers globally when engine downtime threatens operational schedules.

The main pain point is securing Locomotive Parts that guarantee dimensional precision and material integrity. Failure to do so leads directly to catastrophic crankshaft failure and costly EMD engine downtime.

Substandard or counterfeit components, particularly critical items like the Thrust Washer (often referenced by EMD Part No. 40102453), lead to rapid axial movement, excessive wear, and premature engine shutdown. When sourcing EMD Parts, you need immediate, certified solutions backed by robust quality control to ensure fleet reliability.

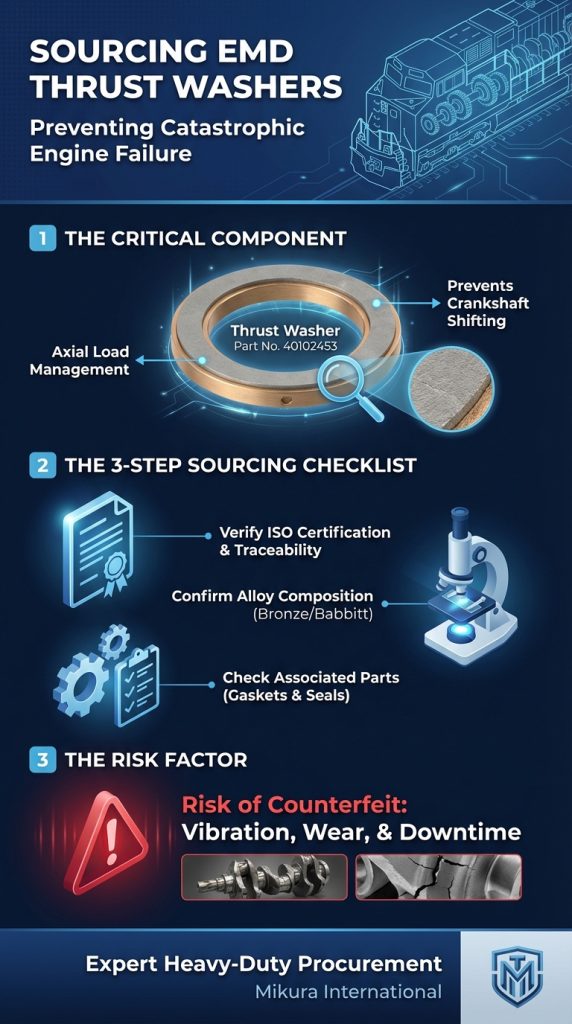

To overcome the critical pain points associated with sourcing reliable EMD engine components, follow these essential procurement steps:

- Verify the supplier’s ISO certification and traceability documentation for all EMD Manufacturers and parts.

- Insist on material certification for the component, especially the specific alloy composition of the Thrust Washer.

- Prioritize suppliers specializing in heavy-duty diesel engine components, including Cylinder Head Seat Rings and specialized Gasket sets.

- Confirm the supplier’s stock includes related critical items like Expansion Joints and the Joint Assembly for complete engine overhaul kits.

- Always verify that the EMD Part No. matches the required specification to ensure compatibility with your engine model.

- Choose a partner that guarantees on-time delivery to minimize operational delays and maximize locomotive uptime.

Immediate Steps to Overcome Thrust Washer Sourcing Pain Points

Engine reliability hinges on the quality of every component, especially high-wear items like the Thrust Washer. Substandard components lead directly to catastrophic failures and massive operational losses.

To mitigate risk and ensure you receive genuine Locomotive Parts quickly, follow these actionable steps for securing critical EMD Parts:

- Verify the supplier holds valid ISO certification and specializes exclusively in heavy-duty industrial diesel engine parts, covering EMD, ALCO, and GE platforms.

- Always cross-reference the required EMD Part No, such as the critical 40102453, against the supplier’s comprehensive product catalog indexing.

- Request detailed quality assurance documentation, specifically metallurgical reports, ensuring the bronze or babbitt composition of the Thrust Washer meets strict OEM standards.

- Ensure the supplier maintains substantial inventory of high-wear items, from Thrust Washers to Cylinder Head Seat Rings and Viton Seals, to guarantee urgent, on-time delivery.

- Confirm the parts are manufactured to meet or exceed OEM specifications for precise fit, crucial for components installed near the Crankcase or Exhaust Manifold.

- Look for proven expertise in both EMD 645 and 710 series engine components, including specialized items like Turbocharger Parts and precision Gasket kits.

- Inquire about the supplier’s quality control processes to ensure the integrity of all specialized Locomotive Parts sourced, including Expansion Joints and Joint Assembly components.

The Critical Function of EMD Locomotive Thrust Washers

The Thrust Washer is a deceptively simple component with an overwhelmingly critical job in any EMD engine.

It is the primary manager of axial forces, preventing the massive crankshaft from shifting back and forth within the engine block.

Without precise axial control, you risk immediate damage to the main bearings, connecting rods, and the entire gear train, a catastrophic failure for any locomotive.

Understanding Axial Load Management

EMD locomotive engines generate substantial thrust loads, particularly during dynamic braking or rapid acceleration. The integrity of your Thrust Washer is non-negotiable under these conditions.

The washer absorbs this force, maintaining the specified end play clearance required for smooth operation of all Heavy Duty Diesel Engine Parts.

If the washer wears down, that critical clearance increases, leading to destructive vibration and ultimately, component failure across the drivetrain.

The Cost of Compromising on EMD Parts Quality

When sourcing replacement parts, maintenance managers must look for certified EMD Parts Manufacturers.

Low-quality components accelerate wear, forcing premature replacement of high-cost assemblies like the Turbocharger or the Exhaust Manifold.

High-quality replacement parts, like the common EMD Part No 40102453, are manufactured using specific alloys designed for maximum wear resistance and minimal friction.

The integrity of the Thrust Washer directly dictates the lifespan of the crankshaft and the overall reliability of your locomotive. Compromising on quality here guarantees costly downtime later, requiring extensive Gasket and seal replacement kits.

Associated Component Integrity

A failure originating at the Thrust Washer often necessitates a complete engine tear-down and the replacement of all related seals and Gasket assemblies.

Sourcing genuine components ensures dimensional accuracy, which is vital when reassembling complex areas like the Cylinder Head Seat Ring or the Lube Oil Separator assembly.

Always verify the material specifications for critical seals, ensuring components like the Gasket Exhaust Manifold and Crankcase Gasket meet the necessary heat and pressure resistance standards.

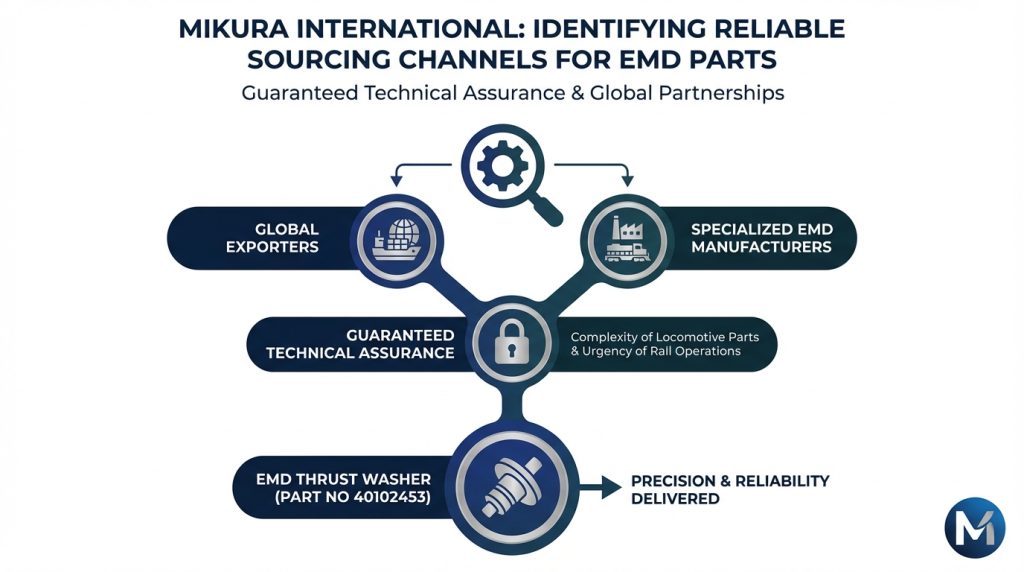

Identifying Reliable Sourcing Channels for EMD Parts

When seeking genuine components, sourcing is about guaranteed technical assurance, not merely availability.

You require partners who deeply understand the complexity of EMD Locomotive Spare Parts and the absolute urgency of rail operations.

The most reliable sources are established global exporters and specialized EMD Manufacturers who focus exclusively on heavy-duty industrial components.

When ordering critical components like the EMD Thrust Washer (often referenced by EMD Part No 40102453), precision is non-negotiable.

Technical Vetting: Beyond the EMD Part No

When evaluating potential suppliers, focus keenly on their technical capabilities and established logistics framework.

A trustworthy supplier will stock not only the core Thrust Washer but also related critical sealing components.

This includes the high-tolerance Cylinder Head Seat Ring (Viton) and critical gaskets like the Crankcase Gasket and the Gasket Lube Oil for the Lube Oil Separator.

The Importance of Quality Control and Certification

Look for evidence of stringent quality control processes and guaranteed material traceability.

Suppliers must demonstrate competence in handling high-precision moving parts like the Water Pump Shaft and complex assemblies like the Joint Assembly for Expansion Joints.

For many global fleet operators, sourcing high-precision EMD Parts Manufacturers India based companies offers a crucial combination of cost-effectiveness and rigorous ISO-certified quality standards.

These manufacturers often specialize in providing comprehensive kits, such as the Turbocharger Changeout Kit or the Gasket Changeout Kit, ensuring all necessary seals are included.

Assessing Industrial Competence

Verify their industrial competence by checking their experience supplying parts for both EMD and ALCO engines.

This ensures they handle the full range of heavy-duty components, from Turbocharger Parts and the Exhaust Manifold to precision items like the Cylinder Liner and Valve Seat Inserts.

A supplier with broad industrial focus understands the compatibility requirements across various heavy-duty diesel engine parts.

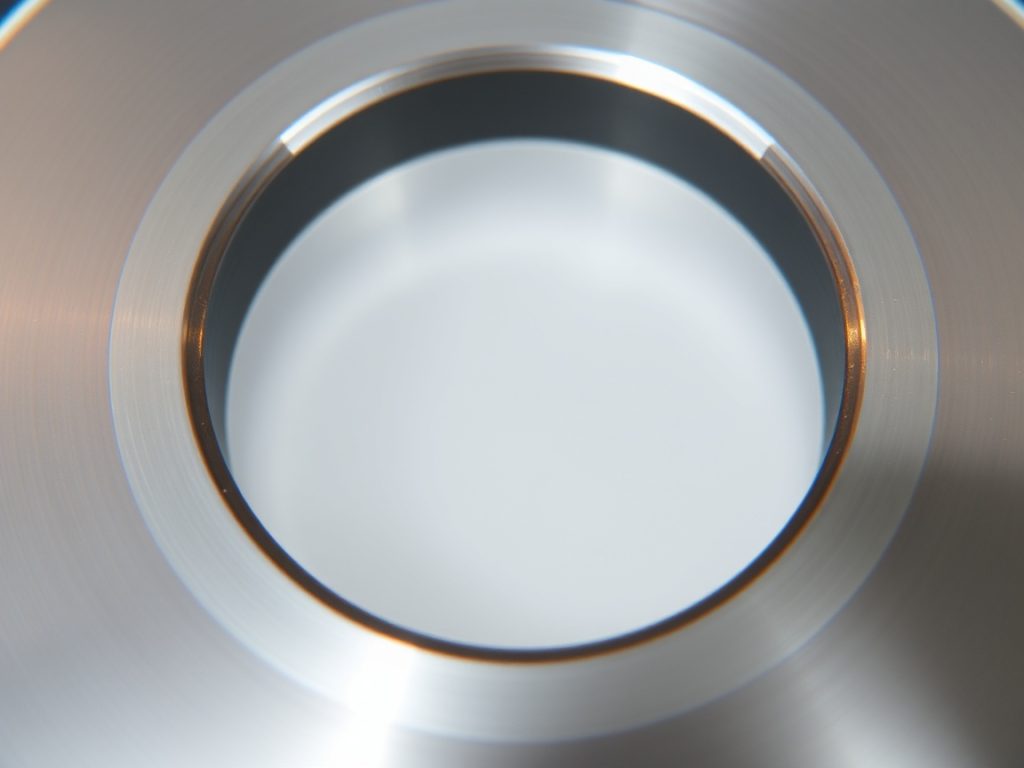

Technical Specifications and Quality Verification of EMD Thrust Washers

The reliability of your heavy-duty diesel engine depends entirely on stringent technical verification. Procuring the correct Thrust Washer requires deep knowledge of material science and precise Industrial Component Numbering.

These critical Locomotive Parts are typically forged from high-load bronze alloys, often utilizing tin-lead plating to ensure a low-friction interface against the hardened crankshaft steel.

Dimensional precision is non-negotiable. Components must adhere strictly to established EMD Part No standards to guarantee perfect Engine Component Compatibility across the entire power assembly.

The Risk of Substandard EMD Parts

Precision is paramount. Even marginal deviation in specification can lead to catastrophic end play, resulting in total engine failure and massive downtime. You require suppliers who understand the difference between a replacement part and a technically certified component.

Here is a comparison of typical requirements for high-demand Thrust Washer types used in EMD engines, detailing why sourcing integrity is paramount:

| Specification Feature | Standard EMD 645/710 Requirement | Risk of Substandard Component |

|---|---|---|

| Material Composition | High-load bronze alloy, often with tin-lead plating | Rapid scoring, premature wear, and material flaking |

| Thickness Tolerance | +/- 0.0005 inches | Incorrect crankshaft end play, leading to catastrophic failure |

| Surface Finish (Ra) | Micro-polished for optimal oil retention | Increased friction and heat generation at high RPM |

| Part Number Example | 40102453 or equivalent | Mismatch in size or load rating, invalidating warranty |

Verifying Quality Across Related EMD Components

Verification extends beyond the washer itself. You must demand full traceability and quality certifications from your supplier, especially when dealing with high-wear items.

Reliability in a Thrust Washer is directly linked to the quality of other critical EMD Parts. A trusted supplier will offer a comprehensive Product Catalog Indexing system covering components from the Cylinder Liner and Valve Seat Inserts to the complete Turbocharger Changeout kit.

Ensure your sourcing partner understands the full scope of engine overhaul kits, including specialized sealing solutions like the Viton Seal for the Cylinder Head Seat Ring and precision cuts required for the Gasket Exhaust Manifold and Crankcase Gasket.

This attention to detail must extend to all ancillary systems, including the integrity of Expansion Joints and the Joint Assembly used in the exhaust system.

Always prioritize suppliers who detail their use of advanced manufacturing, including the application of specialized coatings like Chrome Plating Technology on components such as the Water Pump Shaft and Cylinder Liner. This holistic approach minimizes unexpected downtime caused by related component failure.

Maintaining Engine Integrity: Integrated Gasket, Seal, and EMD Expansion Joints

Replacing a critical component like the Thrust Washer demands a holistic approach to engine maintenance. The integrity of surrounding seals, gaskets, and joints is non-negotiable.

Engine stability and uptime rely on addressing related systems simultaneously, particularly those managing exhaust flow and crankcase pressure. Ignoring these associated EMD Parts leads directly to costly operational downtime.

Securing Critical Seals: The Necessity of EMD Gasket Changeout Kits

A common operational pain point for Locomotive Parts maintenance is leakage around the Turbocharger and exhaust system.

When performing a major service, always ensure you have a complete Kit Gasket or Gasket Changeout Kit ready.

Critical seals include the Gasket Turbocharger connection to the Exhaust Manifold. Securing the Gasket Exhaust Manifold connection prevents heat loss and maintains optimal turbo performance.

Furthermore, maintaining crankcase sealing integrity is paramount for proper oil pressure. You must source the correct Gasket Chamber and Crankcase Gasket components to prevent oil leaks and maintain engine efficiency.

Reliable suppliers offer comprehensive kits for components like the Lube Oil Separator, ensuring all necessary Gasket Lube Oil seals are included for a complete and reliable service.

Thermal Management: EMD Expansion Joints and Turbocharger Efficiency

High operational temperatures in the exhaust system necessitate durable, precision-engineered EMD Expansion Joints.

These crucial Locomotive Parts manage significant thermal expansion between the engine block and the Turbocharger housing.

They are often supplied as a complete Joint Assembly to guarantee perfect fitment and function.

Failure of these Expansion Joints directly causes exhaust leaks, leading to a critical loss of turbo boost and severely reduced locomotive power output.

Ensure your supplier has expertise in Turbocharger Parts, including specialized seals for connections like the Adapter to Turbocharger.

Cylinder Head Integrity: Sealing the Combustion Chamber

Do not overlook the Cylinder Head during major engine service. Precision components like the Cylinder Head Seat Ring are essential for maintaining combustion efficiency in Heavy Duty Diesel Engine Parts.

When dealing with extreme heat applications, only source seals utilizing materials like Viton Seal technology. This ensures longevity and resistance to high temperatures and corrosive chemicals.

Proper sealing of the Cylinder Head Seat components is critical to prevent water or oil ingress into the combustion chamber, protecting the entire engine system.

Sourcing these comprehensive EMD Parts ensures that your investment in a new Thrust Washer is protected by the integrity of the entire engine assembly.

Practical Strategies for Urgent Component Procurement

In locomotive maintenance, component procurement is a race against the clock. Every hour of downtime directly impacts revenue and delivery schedules.

Securing genuine EMD Parts quickly requires a supply chain built entirely on speed and trust.

Prioritizing Urgent Logistics

You need a partner with global supply chain expertise. Look for an exporter that understands international logistics and customs procedures, minimizing transit delays.

Mikura International, for instance, operates with core values centered on urgency in response to inquiries and guaranteed on-time delivery, critical for global maintenance operations.

This focus ensures critical components, from the EMD Thrust Washer to the complex Joint Assembly for the turbocharger system, reach your facility fast.

Ensuring Financial and Transit Transparency

When sourcing specialized items, verification is key. Always look for suppliers who offer transparent tracking and flexible shipping terms, whether FOB or CIF.

For high-value, specific components like the EMD Thrust Washer (often tracked by EMD Part No. 40102453), clear documentation guarantees authenticity and speed.

Precision Sourcing: The Power of Comprehensive Cataloging

Do not waste critical time searching for individual components or cross-referencing obsolete numbers.

A high-quality parts manufacturer provides detailed Product Catalog Indexing that instantly cross-references both EMD and ALCO part numbers.

This efficiency extends to sourcing less common, yet vital, parts like Valve Seat Inserts or specialized seals for the Accessory Drive Housing.

Verification: Maintaining Engine Integrity

The integrity of surrounding components, such as the Crankcase Gasket, Gasket Lube Oil Separator, or the Gasket Exhaust Manifold, cannot be compromised.

Always verify the supplier’s quality control process, especially for precision items like the Cylinder Head Seat Ring (Viton Seal).

Choosing certified suppliers ensures engine component compatibility and longevity, crucial when dealing with critical systems like EMD Expansion Joints.

The Advantage of Complete Maintenance Kits

To further reduce procurement complexity, focus on suppliers that offer complete system solutions, not just single parts.

A Gasket Changeout Kit or a complete Turbocharger Changeout package should include every necessary component, seal, and Gasket Chamber item required for the repair.

This approach prevents delays caused by missing small, yet critical, items during a major repair, such as replacing the Cylinder Liner or components of the Lube Oil Separator.

Maintaining Engine Component Compatibility

Engine component compatibility is non-negotiable in EMD architecture. After securing urgent component delivery, the next critical step is verifying dimensional precision and material integrity.

The EMD engine demands strict adherence to dimensional standards. Failure here leads directly to catastrophic failure, such as seized bearings or damaged crankshafts, the exact disaster a faulty Thrust Washer is meant to prevent.

When installing new components, especially those related to the power assembly and rotating elements, compatibility dictates the engine’s operational lifespan.

Dimensional Accuracy and Power Assembly Integrity

The core components of the power assembly require micron-level precision. Even minute variances in dimensions can compromise performance.

For example, the precise fit between the Cylinder Liner and the engine block must be perfect to ensure proper heat transfer and maintain compression integrity. Similarly, the thickness and flatness of the replacement Thrust Washer must match the EMD Part No specification exactly to control crankshaft end play.

Sourcing quality Locomotive Parts from reliable EMD Manufacturers ensures that components are designed for the rigorous environment of heavy-duty diesel engine parts.

Verifying Material Grades for Longevity

Dimensional fit is only half the equation. You must scrutinize the material integrity of all replacement components.

Substandard metals or alloys in critical parts lead to premature wear under high load conditions, regardless of initial fit. Always check the material grade of the replacement part against the OEM standard, focusing on durability under extreme thermal and mechanical stress.

This is crucial for items like the Cylinder Head Seat Ring (Viton) and the Valve Seat Inserts, which operate directly in the combustion zone.

Sealing Systems and Peripheral Components

Compatibility extends to all sealing systems and accessory components. A complete overhaul requires attention to every detail, ensuring the longevity of the entire system.

When performing maintenance on the exhaust system, verify the quality of the Gasket Exhaust Manifold and the integrity of the Expansion Joints and Joint Assembly. These components must manage intense thermal cycling associated with the Turbocharger system.

Furthermore, ensure that all necessary seals, such as the Gasket Lube Oil for the Lube Oil Separator or the various seals in the Kit Gasket, meet the high standards required for EMD Parts operating in demanding locomotive applications.

Frequently Asked Questions Regarding EMD Component Sourcing

What is the typical lifespan of an EMD Thrust Washer?

The lifespan of a genuine EMD Thrust Washer is highly dependent on operational variables: engine load, precise maintenance schedules, and oil quality.

A high-specification component should reliably last through several scheduled overhaul cycles. The critical factor is consistently monitoring the crankshaft axial end play; excessive play accelerates wear dramatically, threatening catastrophic failure.

How do I verify the authenticity of EMD Part No 40102453?

Verifying authenticity requires demanding comprehensive certification and traceability records from your supplier. You must ensure the EMD Part No 40102453 meets the exact dimensional tolerance and metallurgical composition defined by EMD Manufacturers.

Look for suppliers who are certified members of recognized industrial bodies, such as the EEPC or MCCIA. This confirms ethical business practices and adherence to stringent quality control standards required for critical Locomotive Parts sourced from reliable Parts Manufacturers India.

What other critical seals and Gaskets require replacement during this maintenance?

Since this repair necessitates significant engine disassembly, it is highly recommended to perform a comprehensive seal and Gasket inspection.

We advise ordering a complete Kit Gasket or Gasket Changeout Kit. Key components to inspect and replace include the Crankcase Gasket, seals associated with the Accessory Drive Housing or Camshaft Drive Housing, and the Oil Pan gasket.

Furthermore, check the seals for the Lube Oil Separator, and if performing a wider inspection, inspect the Gasket Exhaust Manifold and related Turbocharger Parts, especially if a full Turbocharger Changeout is being considered.

Can I use marine engine thrust washers in a locomotive EMD engine?

While EMD utilizes similar engine families (like the 645 and 710) for both marine and locomotive applications, component interchangeability is rarely guaranteed.

The specific component numbers and load ratings differ significantly due to the unique demands of traction service versus continuous marine duty. Always reference the official Locomotive Parts Manufacturing catalog for rail applications to ensure the Thrust Washer meets the specific operational stresses.

Why are the Cylinder Head Seat Ring (Viton) and related components often discussed alongside main bearings?

The Cylinder Head Seat Ring (Viton) and other power assembly components, such as the Cylinder Liner and Valve Seat Inserts, are critical for maintaining compression and sealing combustion gases.

While the Thrust Washer addresses axial movement at the crankshaft, these components are all part of the larger engine overhaul. Reliable suppliers stock these critical items together, including the Head Seat Ring and Viton Seal, ensuring you can execute a full overhaul without delay. This holistic approach is essential when dealing with Heavy Duty Diesel Engine Parts like EMD and ALCO components.

Should I inspect EMD Expansion Joints during a major overhaul?

Absolutely. If the engine is opened for major repairs, inspecting the EMD Expansion Joints and related Joint Assembly is crucial for preventing exhaust leaks and maintaining Turbocharger efficiency.

Faulty Expansion Joints can lead to serious performance issues, often requiring replacement Gasket Chamber components. Sourcing high-quality replacements alongside your Thrust Washer is a vital part of proactive maintenance planning.

Infographic Summary